Triangular Form Traveller in High Quality

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

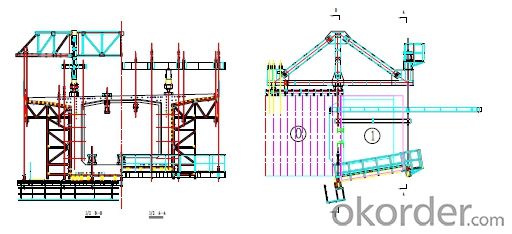

TRIANGULAR FORM TRAVELLER

Trianngular form traveler has the advantages of low gravity of front

trancerse beam, safe & easy operation, easy fixing, and safty during

walking, etc..

During the designing of the form traveller, we always provide

different modes of traction, such as hydraulic pushing mode or

pulling mode, and chain hoist mode, etc. to the constructors for their

choice.

The design of the form traveller could be divided into two types:

external sliding girder and self-moving exteral formwork according to

de construction conditions. When the site condition does not allow

to remove the form traveller at the closure part which have to go

backwards to segment, the second type is suggested.

● Low gravity of front trancerse beam

● Applicable to large-scale stay-cable cantilever casting bridge with wide bridge deck

● Safe & easy operation, easy fixing, and safty during walking

● Big operational space under the main frame, and easy installation and removal

- Q:I would like to ask a joint (32m+48m+32m) continuous beam cantilever hanging basket perfusion, each phase of the most reasonable construction cycle is how long (in days), thank you

- Continuous beam of a block of the construction period of about 10 days to about 12 days, the 10 day is a bit illegal operation

- Q:Hanging basket construction steel binding labor costs a ton of money

- Steel straight, processing, assembling, derusting, welding, sleeve connection, transportation, installation, transportation and other mold materials on-site and reinforced construction about everything related ancillary work

- Q:The post tensioned prestressed anchorage of suspension bridge can be reused?

- Obviously not, after a method is used to anchor the pre-stressed anchorage prestressed reinforcement

- Q:You know how space travelers are astronauts and time travelers are crononauts? Well, what is the naut form of an inter dimensional traveler? (Obviously in fiction).

- Internaut? ;) I don't think one exists yet. You could try making it up. If Cosmos is the universe and inter-dimensional travel is travelling between different parallel universes, maybe it should be Cosmonaut (though the Russians already took that one...)

- Q:Construction technology of hanging basket construction:

- Short platform composite hanging basket construction: short platform composite hanging basket by hanging basket platform, tripod and servo system (including cable system, suspension system, walking system, anchorage system, horizontal support system, fine positioning system) three parts. As shown in the construction of the main girder section, under the condition of the front suspension and the pull rope, it must ensure that the front boom is under tension, and the tension value must be within the scope of the design. To install the dynamometer. Self-propelled front fulcrum hanging basket construction either truss or cable-stayed type are the fulcrum of form for the widespread use of cantilever hanging basket, the basket is a single cantilever force under negative bending moment is large, so the concrete segment length limitation. The front pivot hanging basket can make full use of the action of the stay cable and the negative moment of the cantilever is the force of simply supported positive bending moment. The pouring length and bearing capacity can be greatly improved. 1 hanging basket hanging void, at this point the anti force downward force to the hanging beam hanging basket, hanging basket and the longitudinal beams under negative bending moment.

- Q:80m hanging basket construction section of how to pull tension longitudinal reinforcement? At this point both ends of the concrete, how to pull ah

- Internal tooth block! You look at the construction plans will know.

- Q:How to evaluate the construction scheme of bridge hanging basket

- Hanging basket construction is a more common construction, the expert review is only for some non common problems to discuss the refinement

- Q:Hanging basket dry steel, steel hinge line, how much money a ton. How much money one concrete

- 580 or so, including: equipment installation, removal, transportation, raw materials distribution, loading and unloading vehicles, on-site storage and storage;

- Q:After the completion of prestressed tension grouting on the basket can move forward

- [prestressed grouting is not completed after the hanging basket forward is not allowed] duct grouting has two main purposes: one is to protect the steel wire no rust, prolong the service life of structure, so the grouting be plump and compact; two is as a medium in relaxation steel strand, to transfer beam a part of stress.

- Q:Hanging basket in the construction of the 2 block construction is also need to press it

- 6 when you walk in the basket, be sure to move smoothly.7 cantilever pouring concrete should be from the basket to the front of the basket to the end of the basket.8 jack is an important tool in construction, must be carefully maintained.9 walking system should be lubricated regularly.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Triangular Form Traveller in High Quality

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords