Tri HDPE Geocomposite Drainage for Slope Protection Best Quality

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

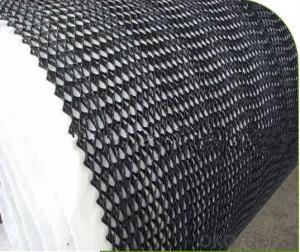

Tri HDPE Geocomposite Drainage for Slope Protection

Description :

Drainage Geocomposites GCD is a high drainage capacity geocomposite, consisting of a flexible and high compressive strength HDPE Geogrid, covered by non woven-needle punched PP polypropylene geotextiles on one or both sides. Also available in PES polyester, HDPE high density polyethylene, coloured - recycled or waterproof one side.

This structure provides for high flow rates for the life of a drainage structure, not just for few hours. Therefore TENAX TENDRAIN are triplanar geocomposites engineered for long term drainage in waste containment application characterized by the following

Ability of the drainage structure to maintain high long term in-plane flow;

Ability of the drainage structure to withstand long term compressive loads;

Ability of the drainage structure to provide adequate shear stability.

Application:

Water Lagoons

Lagooning and Water Treatment Tanks,

Reservoirs, Liquid

Waste Ornamental Ponds,

Golf Courses

Drainage and Filtration

Landfill CappingTailing ponds,

Leach miningVertical Barriers

Erosion ControlTunnels

Linear and Surface Works

Consolidation of Margins Building – Parking:

Features:

1)Excellent drainage function, can bear long time hige press load

2)High tensile and shear strength

3Reduce the rate geotextile embedding into the core of geonet, can protect long time stable water conductivity

4)Tri-dimension composite geonet for drainage can bear more than 2000kpa compression load

5)Its anti-compression capacity is much larger than common geonet for drainage

6) Certificate :ISO14001:2004, ISO9001:2008

Specifications and technical parameters:

Drainage network core | units | Specification | ||||

Unit weight | g/m2 | 750 | 1000 | 1300 | 1600 | |

Thickness | Mm | 5.0 | 6.0 | 7.0 | 7.6 | |

Hydraulic conductivity | m/s | kx10-4 | Kx10-4 | Kx10-4 | Kx10-4 | |

Elongation | % | 50 | 50 | 50 | 50 | |

Tensile strength (core netwaork) | kN/m | 8 | 10 | 12 | 14 | |

Geotextile | g/m2 | Heavier grades of geotextiles can be bonded to geonet on request | ||||

FAQ

Questions and Answers:

Q: Can you accept sample order?

A: Yes, we accept samples with little and reasonable charge.

Q: What is your MOQ?

Q:How about your quality?

A: Try a small order, you will have your own judgment!

- Q:How do geocells help in slope protection applications?

- Geocells provide effective slope protection by improving soil stability, preventing erosion, and enhancing overall slope integrity. They act as a confinement system that reinforces the soil, creating a grid-like structure that distributes and absorbs the forces exerted on the slope. This helps to prevent soil movement, erosion, and landslides, thereby ensuring long-term stability and durability of the slope.

- Q:What are the different types of geocomposites used in earthwork?

- There are several types of geocomposites used in earthwork, including geotextile-geogrid composites, geotextile-geocell composites, and geotextile-drainage composites. These geocomposites are designed to provide reinforcement, stabilization, and drainage capabilities, depending on the specific needs of the earthwork project.

- Q:What are the four major mechanics in civil engineering?

- Should be theoretical mechanics, material mechanics, structural mechanics, soil mechanics

- Q:How do earthwork products contribute to water conservation?

- Earthwork products, such as rainwater harvesting systems, permeable pavements, and bioswales, play a significant role in water conservation. These products are designed to manage and control stormwater runoff effectively, reducing the amount of water that enters the drainage system or gets wasted. By collecting and storing rainwater, these systems help replenish groundwater resources and reduce the burden on municipal water supplies. Additionally, earthwork products can enhance the natural filtration of water, removing pollutants and contaminants before they reach water bodies, thereby improving overall water quality.

- Q:Civil Engineering Materials. e Material saturated with water, and then dry the surface, is the hole filled with water or closed hole filled with water? What is the condition of putting the material in a jar filled with water? Not to say that the closed hole is not water?

- Civil Engineering Materials. e Material saturated with water, and then dry the surface, is the hole filled with water or closed hole filled with water? What is the condition of putting the material in a jar filled with water? Not to say that the closed hole is not water?

- Q:What are the benefits of using geosynthetic clay liners in golf course ponds?

- Geosynthetic clay liners offer several benefits in golf course ponds. Firstly, they provide excellent hydraulic performance by reducing water seepage, thus helping to maintain the desired water levels in the ponds. Secondly, these liners are highly resistant to chemical degradation, ensuring the water quality remains optimal for irrigation purposes. Additionally, geosynthetic clay liners act as a barrier, preventing the migration of contaminants from the surrounding soil into the pond, thereby protecting the ecosystem. Lastly, these liners are easy to install and require minimal maintenance, making them a cost-effective solution for golf course pond management.

- Q:Can earthwork products be used for constructing horse riding arenas?

- Yes, earthwork products can be used for constructing horse riding arenas. Earthwork products such as gravel, sand, and clay can be used as base materials to create a suitable and stable surface for horse riding arenas. These materials provide the necessary foundation to support the weight and movement of horses, ensuring a safe and functional riding area.

- Q:What are the different applications of geogrids in road and railway construction?

- Geogrids have various applications in road and railway construction. They are commonly used for soil stabilization, reinforcement, and erosion control. Geogrids help to distribute loads, increase the strength and stability of the ground, and prevent the movement of soil particles. In road construction, geogrids are used for base reinforcement, subgrade stabilization, and pavement overlay. They can also be utilized in railway construction for ballast reinforcement, track bed stabilization, and slope protection. Overall, geogrids play a crucial role in enhancing the durability, performance, and longevity of roads and railways.

- Q:Can earthwork products be used for retaining walls?

- Yes, earthwork products can be used for retaining walls. Earthwork products such as geogrids, geotextiles, and geomembranes are commonly used in retaining wall construction to provide stability, erosion control, and reinforcement. These materials help to retain the soil behind the wall and prevent it from moving or eroding, ensuring the structural integrity of the retaining wall.

- Q:Are earthwork products suitable for use in swimming pool construction?

- Yes, earthwork products can be suitable for use in swimming pool construction. These products, such as compacted soil or fill materials, can be used to create a stable base for the pool, ensuring proper drainage and preventing shifting or settling of the pool structure. Additionally, earthwork products can be utilized for grading and shaping the surrounding landscape, providing a visually appealing and functional pool area.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Tri HDPE Geocomposite Drainage for Slope Protection Best Quality

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords