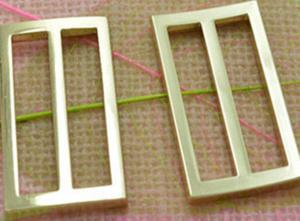

Tri-glide with Cold Rolled Steel for Handbags

- Loading Port:

- Yantian

- Payment Terms:

- TT or LC

- Min Order Qty:

- 200000 pc

- Supply Capability:

- 10000 Pieces per Day pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details of Tri-glide For Handbags

Material:Stainless Steel, Cold Rolled Steel

Finish

Specifications of 100 coatings are available in a range of colors

Quality Control:

1.ISO approved.

2.Inspection at site.

3.Inspection before shipping.

4.testing machine.

Fetures:

A: Eco-friendly( could be Nickel Free, Lead Free)

B: Zinc alloy, with long lasting plating

C: Top quality products in China

D: With more than 15 years rich experiences, make perfect products.

Specifications of Tri-glide For Handbags

Size(inner) :

8mm,10mm,12mm,18mm,20mm,26mm,32mm,38mm,40mm,etc.

Special specification and marks can be made according to customers requirements

Usage/Applications

Widely Used for Bags and Paracords.

Packaging & Delivery

Packaging Detail:A: Each one in a polybag, several bags in a inner carton, several inner cartons in an outer carton. B: or according to your request。

Delivery Detail:Upon the quantity of order or as customer requested.

Service we can provide

1. Good after sales service: Any small problem happening will be solved at the most prompt time;

2. We have many years of experience

3. Specifications list is available upon your request

4. Welcome to send enquiry,we will reply soon.If you want to know more,pls feel free to contact us.

5. Prompt shipment with professional documents

6. Packing as your request, with photo before shipment

7. High quality and competitive price

- Q:What is the standard of lifting hook?

- The dangerous section or the hook neck produces the plastic deformation

- Q:Elevator shaft hook is the construction side or elevator shaft, the factory do?

- Usually manufacturers to drawings, and then the construction side as shown in the construction! Organic elevators sometimes have holes in shear walls and floors to facilitate installation in the later stages of the plant!

- Q:How to wear a steel rope for 20 ton double beam overhead crane?

- From the middle of two respectively through the corresponding side of the movable pulley, then upward through the two fixed pulleys corresponding to one side above the rest, and then put down through the following two sides of the movable pulley corresponding to one side, finally to the steel wire rope is fixed on the fixed on the reel.

- Q:There are several kinds of crane hooks

- Crane hook; S hook, nose hook, American hook, claw hook, eye shaped sliding hook, etc..

- Q:What are the dangerous sections of the crane hook

- by the A-A sling tension section on the one hand, the hook has straightened trend; also by the effect of bending moment on the other hand. Because the moment in this section, the bending stress is maximum, this section is a dangerous section.

- Q:CAD how to draw hook

- Well, if you want to paint it yourself, I'll probably tell you about it,,The first part of the 23cm should be no problem, say the hook part..First dotted at the intersection of 24 diameter circle, and then draw T with vertical and tangential circle diameter of 24 intersecting circles, after pruning that arc.. Draw a circle with a radius of 29 and a radius of the right on the same side as the radius of the circle of 24..And then the lower left part, draw a circle with a radius of 36 from the point of intersection of the line, find the intersection of the horizontal line at the bottom of the intersection point of 9 points (because the radius of the tip part of the radius of the circle of 24 tangent). So we can find the intersection of the 24 circles.. Circle at the intersection.The radius of 14 circle and the radius of 29 circle tangent point in the horizontal line intersection point line, so it can draw out.. Then use the tangent radiusDraw a circle with a radius of 2, trim.. Just fine

- Q:How to classify lifting hook? What are the advantages and disadvantages?

- Hook crane is one of the essential part. On the basis of the shape, the hook can be divided into singleanddouble hookhook; the manufacturing method can be divided into forging hook and hook sheet.The utility model has the advantages of easy manufacture and convenient use, and is used for lifting light materials

- Q:Why does the crane have two hooks?

- There are two hooks in the double beam crane is a large tonnage crane, a small tonnage hook, use can be selected according to the use of heavy quality, heavy quality is small small hook can improve the efficiency and energy saving.

- Q:What is the top of the crane hook

- [top] crane hook level of tower crane jib truck trolley for collision with the trolley bottom to prevent the lifting hook up to the highest position, lifting height limiter is arranged on the lifting mechanism, GB5031 tower crane "5.6.1.2" provisions of tower crane trolley, hook up to the top of the device the minimum distance of the lower end of the small frame of 800mm, should be able to immediately stop the lifting movement, but due to falling movement. In the actual operation process of tower crane, lifting height limiter is failure, the driver failed to timely stop hook upward movement, it will form at the top of the lower part of the frame hook device with small collision (also called top), lifting wire rope for hoisting and often pulled off the hook with lifting weights from falling, the consequences are very serious, because the hook hoisting hoisting wire breakage caused by hook falling accidents have occurred in the construction site. There are several reasons for the top:1, crane after a long period of operation of internal parts will occur, such as the relaxation of the upper limit of the screw. When the limiter is loose, the screws on it cannot touch the retainer better.2, because each device has its own service life. If you do not check it on time, the long-term accumulation of the device to limit the potential for more hidden, leading to the occurrence of roof.3, if the joint limiter without sticking occurred lax. Once the limiter fails, it will lead to the top of the hook.4, due to the installation of the crane, the staff did not modulate the order of the controller. At this time, the contacts of the limiter will be hidden, and the top of the case will be produced.5, even if there is no problem in the installation, in the use of still have to pay special attention to. Some of the wrong operation will cause the top.

- Q:Hook crack Hook crack what method of crack detection?what method of crack detection?

- Detection of cracks in general with surface detection (magnetic particle or permeability), high sensitivity. In view of the hook surface oil is more, the effect of penetration test is not good, and the hook is generally ferromagnetic material, so the effect of magnetic particle inspection is good.

1. Manufacturer Overview |

|

|---|---|

| Location | Guangdong, China |

| Year Established | 1992 |

| Annual Output Value | Above US$ 10 Million - US$ 50 Million |

| Main Markets | North America, South America, Eastern Europe, Southeast Asia, Africa, Oceania, Mid East, Eastern Asia, Western Europe, Central America |

| Company Certifications | ISO 9001:2000 ISO 9001:2008 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Shenzhen |

| Export Percentage | 60% - 80% |

| No.of Employees in Trade Department | 301 - 500 People |

| Language Spoken: | English; Chinese; |

| b)Factory Information | |

| Factory Size: | above 2000 square meters |

| No. of Production Lines | |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | High; Average |

Send your message to us

Tri-glide with Cold Rolled Steel for Handbags

- Loading Port:

- Yantian

- Payment Terms:

- TT or LC

- Min Order Qty:

- 200000 pc

- Supply Capability:

- 10000 Pieces per Day pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords