Tri-dimension Compound Geonet/ 3D Composite Geonet for Drainage/ Drainage Tri-dimension Composite

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 900000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

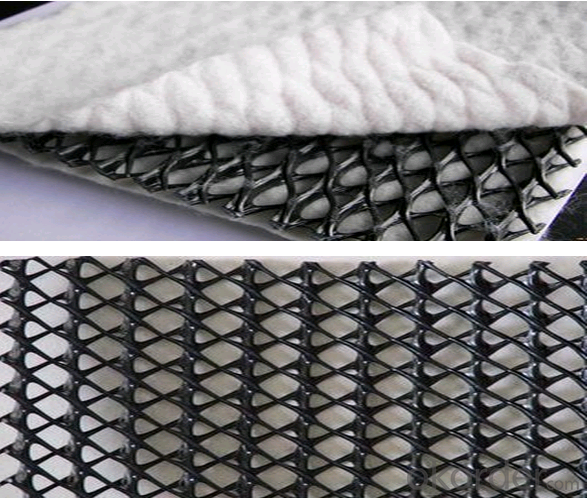

Tri-dimension composite genet for drainage is a new type of geosynthetics.

Its made of atri-dimension geonet coated with geotextile on both sides. Network core consists of a tri-dimension

thick vertical rib, and a rip on top and bottom .

It can drain underground water quickly, also there is a protection system,which can block the capillary water under high load. At the same time, it can also reinforce and isolate of foundation.

Product Uses

1,Landfill drainage;

2, Roadbed and road drainage;

3,Railway drainage, tunnel drainage, underground structure drainage.

4,The retaining back wall drainage,

5,gardens and sports grounds drainage

Functions

Excellent drainage function, can bear long time hige press load

High tensile and shear strength

Reduce the rate geotextile embedding into the core of geonet, can protect long time stable water conductivity

Tri-dimension composite geonet for drainage can bear more than kpa compression load

Its anti-compression capacity is much larger than common geonet for drainage.

Project | Index | |||

GL | GH | |||

GL-1 | GL-2 | GH-1 | GH-2 | |

Tensile strength (MPa) | ≥14 | ≥17 | ≥14 | |

Break elongation (%) | ≥400 | ≥450 | ≥400 | |

Right angle tear strength (N/mm) | ≥50 | ≥80 | ≥50 | |

Carbon black content (%) | ≥2 | |||

Water vapor permeability coefficient (g.cm/(cm.s.Pa) | ≤1.0x10-12 | |||

-70 Low temperature brittleness properties | pass | |||

Dimensional stability (%) | ±3 | |||

FAQ

How about the delivery time?Lead time since receipt of 30% T/T deposit payment: 3 weeks.(Samples will be prepared within 3 days.)

2.What's are the MOQ?Generally speaking, the MOQ is one container, but we can provide you samples for quality inspection.

3. Do you charge for the samples?Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

4. Can you produce according to customers' design?Sure, we are professional manufacturer, OEM and ODM are both welcome.

- Q:What need to pay attention to when choosing the imported geomembrane?

- What needs to note are uniformity of the thickness, acid and alkali resistance, biodegradability, tensile stress limit and puncture strength.

- Q:How do geomembranes perform in extreme weather conditions?

- Geomembranes are designed to perform exceptionally well in extreme weather conditions. These durable synthetic liners have excellent resistance to UV radiation, temperature variations, and extreme weather events such as heavy rain, snow, and freezing temperatures. They maintain their integrity and impermeability, effectively preventing any leakage or seepage. Moreover, geomembranes exhibit high flexibility, allowing them to withstand ground movements caused by earthquakes or freeze-thaw cycles. Overall, their performance in extreme weather conditions is commendable, making them a reliable solution for various environmental and civil engineering applications.

- Q:High density polyethylene root-resistant geomembrane

- High density polyvinyl chloride root puncture resistant geomembrane, aslo called high density PVC root resistant membrane, is a kind of geomembrane which has good seepage-proof effect and good resistance to puncture as well. High density PVC root resistant membrane, with good flexibility and puncture resistance, can be used in a variety of complex construction environment. The width of common High density PVC root resistant membrane in current market is 2m. You can use dedicated welding machine when paving a large area of high density PVC root resistant membrane. Besides, the high density polyethylene root puncture resistant geomembrane in market is also called HDPE root resistant membrane which has better anti-seepage effect, anti-puncture ability and longer service life than High density polyvinyl chloride root puncture resistant geomembrane. It is also cheaper than High density polyvinyl chloride root puncture resistant geomembrane so it can completely replace High density polyvinyl chloride root puncture resistant geomembrane. The width of high density polyethylene root acupuncture resistant geomembrane in current market is 8m, which the common width is 6m. Compared with High density polyvinyl chloride root puncture resistant geomembrane, it can reduce welding cost in construction greatly.

- Q:What are the differences between seepage-proof geomembrane and impermeable geomembrane?

- Just different names, products are the same.

- Q:How do geomembranes contribute to landfill leachate collection systems?

- Geomembranes play a crucial role in landfill leachate collection systems by acting as a barrier to prevent the leachate, which is the liquid produced as waste decomposes, from penetrating into the surrounding soil and contaminating groundwater. These impermeable membranes are installed at the base and sides of the landfill, effectively containing the leachate and guiding it towards collection pipes and sumps for further treatment and disposal. In this way, geomembranes help to minimize environmental impact and protect water sources from potential pollution.

- Q:What are the different kinds of warm reflective film?

- Warm reflective film on the market can be divided into three categories according to material: One is basilemma and the others are fabric basilemma and insulation material composite basilemma. The paper basilemma can also be divided into two categories. One is the paper basilemma (not reinforced). Another is the reinforced paper basilemma (commonly known as reinforced aluminum foil).

- Q:What functions does moistureproof membranes have?

- It prevents moisture and bug bites.

- Q:What is the role of geomembranes in coal seam gas extraction?

- Geomembranes play a crucial role in coal seam gas extraction by acting as a barrier to prevent the migration of gas and other contaminants from the coal seam to the surrounding environment. They are used to line and seal the wellbore and storage ponds, ensuring the containment and safe disposal of wastewater and produced fluids. Additionally, geomembranes help in managing and controlling the water flow within the coal seam, optimizing gas production and minimizing potential environmental impacts.

- Q:How to use electrothermal?film?

- Clip must be used on one of the ends of the wire and then connect the wire, wrap with daub and black rubber in case of electric leakage, and on another end of the wire should be wrapped with professional daub and black rubber in case of electric leakage. It is about 200 watts per square meter.

- Q:Are geomembranes suitable for use in oil spill containment?

- Yes, geomembranes are suitable for use in oil spill containment. They are impermeable barriers that can effectively prevent oil from spreading and contaminating surrounding areas. Additionally, geomembranes are durable, flexible, and resistant to chemicals, making them ideal for handling the harsh properties of oil spills.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Tri-dimension Compound Geonet/ 3D Composite Geonet for Drainage/ Drainage Tri-dimension Composite

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 900000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords