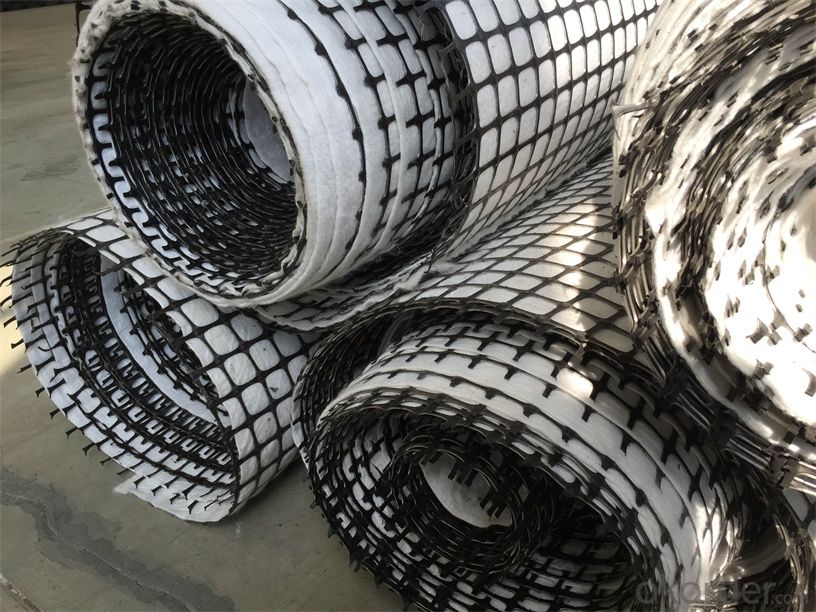

Tri-dimension Composite Geonet for Drainage with Width of 5m

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction

It is a new type drainage material, made of geonet and non woven geotextile, a unique tridimension geonet adhibited geotextile on both sides. It has the property of geotextile and geonet.

Product Application

Landfill drainage, roadbed and road drainage, railway drainage, tunnel drainage, underground structure drainage, the retaining back wall drainage, gardens and sports grounds drainage.

Product Specifications:

Geonet thickness: 5m-8m.

Width: 2m-4m.

Weight of non woven geotextile: 200g/m2.

Length: according to clients' request

Packaging Details:pp woven bags or at your request

Delivery Detail:15 days

Product Property:

It has the property of geotextile and geonet and provide a function system filtration-drainage-protection.

The core of net with its unique tri-dimension structure can bear higher compression load in construction and remain the cerain thickness, provide good water conductivity.

FAQ:

Q: What kind of payments could you support?

A: T/T, L/C, Cash are accepted.

Q: Can we visited your factory?

Y: Yes, warmly welcome to visit our factory.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are freee, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q:How are geosynthetic materials used in railway bridge construction?

- Geosynthetic materials are used in railway bridge construction to enhance the stability and durability of the infrastructure. These materials, such as geotextiles, geogrids, and geocomposites, are incorporated to reinforce the soil, provide drainage, and prevent erosion. They act as a barrier against soil movement, reducing the risk of settlement or slope failure that could compromise the bridge's integrity. Overall, geosynthetic materials play a crucial role in ensuring the long-term performance and safety of railway bridges.

- Q:Are earthwork products suitable for constructing fish ponds?

- Yes, earthwork products are suitable for constructing fish ponds. Earthwork products such as clay, soil, and gravel can be used to create the foundation and structure of a fish pond. These materials provide stability, support, and a suitable environment for fish to thrive. Additionally, earthwork products can be sculpted and shaped to create different pond features like shelves, slopes, and depths, which are important for fish habitat and breeding.

- Q:What are the benefits of using geonets in land reclamation projects?

- Geonets offer several benefits in land reclamation projects, including improved soil stability, enhanced drainage, and increased erosion resistance. They provide a strong reinforcement layer, preventing soil movement and reducing the risk of slope failure. Their high permeability promotes efficient water drainage, preventing waterlogging and allowing for proper soil aeration. Geonets also help control erosion by distributing water evenly and reducing the impact of rainfall on the soil surface. Overall, the use of geonets in land reclamation projects can significantly enhance the long-term stability and productivity of reclaimed land.

- Q:Can geosynthetics be used for reinforcement in airport runways?

- Yes, geosynthetics can be used for reinforcement in airport runways. Geosynthetics such as geogrids, geotextiles, and geocomposites have been successfully employed to enhance the stability, durability, and load-bearing capacity of airport runways. These materials help to distribute the load and provide reinforcement against differential settlement, base course deformation, and lateral movement. Additionally, geosynthetics can improve the overall performance and lifespan of airport runways while reducing maintenance requirements.

- Q:How do geogrids aid in reinforcement of bridge abutments in earthwork projects?

- Geogrids aid in the reinforcement of bridge abutments in earthwork projects by providing stability and increased load-bearing capacity. These high-strength geosynthetic materials are placed within the soil layers surrounding the abutments, creating a composite structure that distributes the load more evenly and prevents excessive settlement. This reinforcement helps to resist lateral forces, such as earth pressure, and improves the overall performance and longevity of the bridge abutments.

- Q:How do geotextile tubes compare to traditional construction methods?

- Geotextile tubes are a more cost-effective and environmentally friendly alternative to traditional construction methods. They offer faster installation, reduced labor requirements, and minimized disturbance to surrounding areas. Additionally, geotextile tubes are highly durable and provide excellent erosion control and sediment containment.

- Q:Can earthwork products be used in retaining walls?

- Yes, earthwork products can be used in retaining walls. Earthwork products such as fill material, geosynthetics, and drainage systems are commonly used in the construction of retaining walls to provide stability, prevent erosion, and manage water drainage.

- Q:Brief description of the application range of Portland cement, ordinary cement, slag cement, volcanic ash cement and fly ash cement

- Slag Portland cement (referred to as slag cement), volcanic ash Portland cement (referred to as volcanic ash cement) and fly ash Portland cement (referred to as fly ash cement) are made of cement clinker. Mixed with the amount of gypsum made of fine. Wherein the variety and the content of the mixed material are different. The mixed material of the slag cement is granulated blast furnace slag, and the blending amount is 20% ~ 70% by weight; the mixed material of the volcanic ash cement is a mixed material of volcanic ash, the dosage is 20% ~ 50% by weight; Fly ash cement in the mixed material is fly ash, blending by weight percentage of 20% to 40%.

- Q:What are the benefits of using geocells for channel protection?

- Using geocells for channel protection offers several benefits. Firstly, geocells provide excellent erosion control by confining and stabilizing soil, preventing it from being washed away by water flow. This helps to maintain the integrity and stability of channels, preventing erosion-related issues. Secondly, geocells promote vegetation growth. The interconnected cells create a stable structure that allows for the growth of vegetation, further enhancing erosion control. The plants' roots intertwine with the geocell structure, reinforcing the channel's stability. Thirdly, geocells are easy to install and require minimal maintenance. They are lightweight and flexible, making them quick and efficient to deploy. Once installed, they require little to no maintenance, reducing the overall costs and efforts associated with channel protection. Moreover, geocells are environmentally friendly. They are typically made from recyclable materials, reducing their ecological footprint. Additionally, their erosion control capabilities help to prevent sediment runoff, protecting water quality and the surrounding ecosystem. In summary, the benefits of using geocells for channel protection include erosion control, promotion of vegetation growth, ease of installation and maintenance, and environmental friendliness.

- Q:How do earthwork products contribute to LEED certification?

- Earthwork products, such as soil, gravel, and mulch, can contribute to LEED (Leadership in Energy and Environmental Design) certification in several ways. Firstly, these products can be sourced locally, reducing the carbon footprint associated with transportation. Secondly, earthwork products can be made from recycled or repurposed materials, promoting resource conservation. Additionally, these products can help with stormwater management and erosion control, which are essential aspects of sustainable site development. Overall, earthwork products play a crucial role in achieving LEED certification by supporting sustainable construction practices and minimizing environmental impact.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Tri-dimension Composite Geonet for Drainage with Width of 5m

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords