Treadmill Golf Pattern PVC Conveyor Belt Treadmill Walking Belt for Gym

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Treadmill Golf Pattern PVC Conveyor Belt Treadmill Walking Belt for Gym

Description of Treadmill Conveyor Belt

PVC light industry conveyor belt

Suitable for light industrial, packing light industrial, transport for tobacco, tea, pieces vegetable, fruit and so on. Also can be used in airport, post office, storage and etc.

PU light industry conveyor belt

Widely used in food industry. Transport the material in bulk, canning and packed In box. The material includes grain, cooky, candy, vegetables, fruit, fowl, meat and so on.

Also widely used in soft material industry. Used in those field, including tobacco, electron, textile, printing and dyeing, machine manufacturing, print and package, paper processing, pottery, marble, wood processing,car shell molding, cable fishing wire, aluminium parts processing and etc.

Features of treadmill belt

thickness:1.4 1.6 1.8 2.0 2.3 2.5 3.1 4.3 4.5 mm

household treadmill: 1.8 2.0 2.3mm

gym treadmill:2.5 3.1 4.3 4.5mm

surface: diamond

color: black blue red grey

Know your treadmill belt

A damaged or worn out belt can be dangerous for you and can quickly wear out electrical components of the treadmill.It is better to replace the belt than to risk an injury or more costly repair.

If your belt is running slow, or feels loose, you may assume that the belt needs to be replaced. Often, though, these are indicators of too tight or too loose tension rollers, and can be fixed by either tightening or loosening the tension rollers.

Surface Patterns:

Flat, Grass , Golf, Diamond, Matte surface finish, Small round particles and etc.

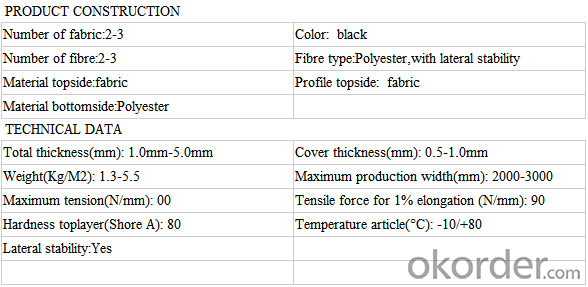

Specification of Treadmill Conveyor Belt

Photos of PVC Treadmill Conveyor Belt

RFQ:

Q: Can you do OEM?

A: Yes, we can do OEM products. It's no problem.

Q: How can I get some samples?

A: 1, We are honored to offer you samples. New clients are expected to pay for the courier cost, the

samples are free for you, this courier cost charge will be deducted from the payment for formal order.

2, Regarding the courier cost: you can arrange a RPI (remote pick-up) service upon Fedex, UPS,

DHL, TNT, etc. to have the samples collected; or inform us your DHL collection account. Then you

can pay the freight direct to your local carrier company.

Q: How do you do regarding quality control?

A: Quality is priority? We always attach great importance to quality controlling from the very beginning to the very end:

1).All raw material we used are environmental-friendly;

2).Skilful workers care every details in handling the producing and packing processes;

3).Quality Control Department specially responsible for quality checking in each process.

Q.What are your payment terms?

A: Standard payment terms are 30%T/T,and balance upon the B/L copy .

L/C at sight is acceptable

Other payment terms can be negotiable.

If you want to find more details about the PVC treadmill conveyor belt, you could make an Inquiry in okorder.com. Okorder.com provides you the products with best price and quality!

- Q:What is the rubber composition and function of the airplane tyres?

- Ethylene propylene rubber and ethylene propylene rubber are synthesized with ethylene and propylene as main raw materials. They are resistant to aging, electrical insulation and ozone resistance. Ethylene propylene rubber can be filled with oil and filled with carbon black. The price of the product is low, and the chemical stability of the ethylene propylene rubber is good. The abrasion resistance, elasticity, oil resistance and the proximity of styrene butadiene rubber are close. Ethylene propylene rubber is widely used. It can be used as tyre, sidewall, rubber strip and inner tube, as well as parts of automobile. It can also be used as wire, cable sheath and high voltage and extra high voltage insulating material. Can also manufacture rubber shoes, sanitary products and other light colored products. It is a chloroprene rubber as the main raw material, made by homopolymerization or copolymerization of small amounts of other. Such as high tensile strength, heat resistance, light resistance, aging resistance and oil resistance properties are superior to natural rubber, styrene butadiene rubber, butadiene rubber. It has a good flame resistance and excellent resistance to burning, its chemical stability is high, water resistance is good. Chloroprene rubber is electrical insulation, cold resistant performance is poor, rubber is not stable in storage. Neoprene is widely used, such as the manufacture of transport belts and belts, wires and cables, and the manufacture of oil resistant hoses, gaskets, and chemical resistant equipment linings.

- Q:What's the difference between rubber and silicone?

- Rubber is widely used, mainly the use of elastic rubber, such as rubber tires, rubber rollers, bridge damping, mainly by the industry; silica gel are mostly used in food life appliances, such as pacifiers, spoon for children, a voltage pot seal.

- Q:When rubber products are hardened, what methods soften?

- Either hardening or vulcanization. Vulcanized rubber becomes elastic rubber. This is an irreversible process. The elastomer can be changed into a plastic regenerated rubber by the desulfurization process.

- Q:Why does rubber stink?

- The word "rubber" comes from the Indian language "cau-uchu", meaning "weeping tree"". Natural rubber is flowing out from the Hevea latex when tapping after solidification and drying process. In 1770, British chemist J. Priestley discovered that rubber could be used to erase pencil writing. The material used at that time was called rubber, which has been used so far. The molecular chain of rubber can be crosslinked, and the crosslinked rubber can recover quickly when it is deformed by external force, and has good physical and mechanical properties and chemical stability. Rubber is the basic raw material of rubber industry. It is widely used in making tyres, rubber hoses, tapes, cables and other kinds of rubber products.

- Q:What about the Poisson's ratio and modulus of elasticity of three yuan ethylene propylene rubber (EPDM)?

- Three yuan ethylene propylene rubber is ethylene, propylene and non conjugated diene three yuan copolymer, began commercial production in 1963. The consumption of the whole world is 800 thousand tons every year. The most important feature of EPDM is its superior oxidation resistance, ozone resistance and corrosion resistance. Because three yuan ethylene propylene rubber belongs to polyolefin family, it has excellent curing property. Of all rubbers, EPDM has the lowest specific gravity. It absorbs large amounts of fillers and oils and has little effect on properties. Therefore, rubber compounds with low cost can be made.

- Q:Will rubber products fade?

- Rubber products will fade, is a rubber aging process, mainly due to external factors, temperature changes, the use of time, light, chemicals, external force and so on.

- Q:What adhesive does rubber and wood have better glue?

- Early rubber was made from latex of rubber trees, rubber grass and other materials made of flexible, insulating, impermeable and air. High elastic polymer compound. It is divided into two kinds: natural rubber and synthetic rubber. Natural rubber is made from rubber, tree, rubber, grass and other plants. The synthetic rubber is obtained by polymerization of various monomers. Rubber products are widely used in industry or in all fields of life.

- Q:How to enhance the performance of water resistant silicone rubber products

- In general, silicone rubber is almost free from the influence of free steam and moisture without pressure. The same is true when the steam is under low or moderate pressure. However, as the vapor pressure rises, the impact on the mechanical properties of the rubber becomes larger. Therefore, silicone rubber is not recommended for long-term use in situations where steam is more than 50psi.

- Q:PVC conveyor belts and rubber belts differ from each other in their respective advantages

- Rubber belts are widely used in conveying equipment, but do you know that proper vulcanization of rubber can maintain high elasticity of rubber and make rubber of a certain strength?. At the same time, in order to increase product hardness, strength, wear resistance and tear resistance, while adding inert filler in the process (such as Zinc Oxide, clay, chalk and barite etc.) and reinforcing filler (such as carbon black), which helps to improve the quality of the conveyor belt.

- Q:What is the relationship between synthetic rubber and crude oil?

- Synthetic rubber also has disadvantages, the drawing effect of main disadvantage lies in its relatively poor, tearing strength and mechanical properties are relatively poor, but because of synthetic rubber materials than natural rubber has the advantages of low cost, but also a lot of Companies in the production of low-end products preferred.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Treadmill Golf Pattern PVC Conveyor Belt Treadmill Walking Belt for Gym

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords