TPt300 BackSheet of Hiuv for Solar Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m²

- Supply Capability:

- 2000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

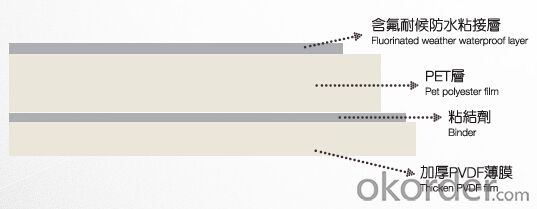

1. Structure of TPt300 BackSheet for Solar Panel

TPt300 BackSheet for Solar Panel is a new generation of backsheet for solar panel, as an important component material of solar panel, new technology helps the backsheet have better performance and wider use. There is 4 layer`s structure of this series: Thicken PVDF film, binder pet polyester film, Fluorinated weather waterproof layer.

2. Main Features of TPt300 BackSheet for Solar Panel

With thicken PVDF film, we have better weathering, water blocking performance compare to PVF film(Tedlar)

More reliable inner film, easier for reworking.

Simple structure makes our BackSheet more reliable, more cost effectiveness.

3. TPt300 BackSheet for Solar Panel Images

4. TPt300 BackSheet for Solar Panel Specification

| Layers of material

| Element | Thickness | Properties |

Weather proof layer | Thicken PVDF film | 43 μm | Weathering & |

Binder | Imported polyester adhesive | 10 μm | Adhesive property |

Thicken PVDF film | White PET | 250 μm | Insulating property \ Mechanical support |

Fluoride weather-water-proof layer | FEVE compound | 3 μm | Weather proof \ water proof \ strong bonding to EVA |

Testing Item | Testing method | Unit | Specification value

|

Thickness | GB/T 13541-92 | μm | 305±10 |

Tensile strength(MD/TD) | ASTM D-882 | N/cm | MD ≥300 TD ≥300 |

Elongation at break(MD/TD) | ASTM D-882 | % | MD ≥100TD ≥80

|

Heat shrinkage rate (MD/TD) | GB/T 13541-92 |

% | MD≤1 TD≤1 |

PVDF/PET peel strength | 180° peel | N/cm | MD ≥5 TD ≥5 |

T-layer cross-cut testing |

GB/T9286-1998 |

level |

0(no drop) |

T-layer cross-cut test after 24 hrs boiling | |||

Peel strength with EVA film | 180° peel | N/cm | ≥40 |

Breakdown voltage | ASTM D-149 | KV | ≥17 |

Partial Discharge | IEC 60664-1 | VDC | ≥1000 |

Moisture vapor transmission rate (MVTR) | 38℃,90%RH |

g/day.m2 |

≤2 |

5. FAQ

1. How to choose backsheet for solar panel?

It’s not easy question, but the first but most important thing is that the life period of the solar panel depends on the material quality of the backsheet.

2. If there is some scratches on the backsheet, how to deal with the solar panel?

Firstly, the scratch will destroy the waterproofness of the solar panel through the backsheet, which will finally have bad influence on the performance of the panel,; then the scratches on the backsheet should be regarded as defective and you should contact with the supplier or manufacturer to change it as soon as possible.

3. What is the color that backsheet should be?

Absolutely is white. As time goes by, the corrosion of the backsheet makes the white color into yellow. So make sure when you get the new solar panel the backsheet is in appropriate state.

- Q:Solar garden lamp product parameters

- Rainy days guarantee: can work continuously for more than 15 rainy days (regional / seasonal different) (can be made on request)Without the need for laying underground cables, without payment of lighting, key components of solar panels, solar garden lights the solar street lamp intelligent controller, DC maintenance free storage battery and a lighting lamp through the national development and Reform Commission, the world bank /GEF/ photovoltaic products certification. The utility model is mainly suitable for the lighting and lighting of the city road, the small square, the industrial park, the scenic spot, the park green belt, etc..

- Q:Now there is no sun, cloudy days can use solar products?

- The amount of radiation of solar water heater is the meaning of the sun. The sun did not reach that he cannot.

- Q:The advantages and disadvantages of solar energy?Want to buy solar energy solar energy what is bad? Know about

- I personally think that the use of solar energy is not very environmentally friendly, because the market is currently the main products of solar energy use monocrystalline silicon or polysilicon, thin film with very little. We all know that silicon is a heavy metal, pollute the environment and can not be removed, because the film component cheap but the conversion rate is low, can only be used in small products, such as computer, application of technology products such as lamps, although the silicon conversion rate is high but the price is expensive, so the application of products currently on the market to see the most use of polysilicon, 25 years after this type of product, service life expires, how to deal with??? Is a problem, so I still want to improve the conversion rate of thin film components.

- Q:Product category and comparison of solar thermal utilization

- What is the reason?The main reason is that China's solar energy (water heater) is the most in-line vacuum tube solar water heater, vacuum tube itself is vulnerable, tube explosion caused by vibrations, icing, improper water and other reasons, the vacuum tube fouling phenomenon is very serious, affecting the normal use, needs a great amount of customer service service, high maintenance costs. Once, encountered bad weather, frequent accidents, too busy to attend to all enterprises and dealers.Where is the way out?According to the experience and lessons of foreign countries, the use of a new type of high-performance flat solar energy is the most feasible and effective solution.

- Q:What are the third generation solar cells

- Major technical breakthrough:Multi junction solar cellNanostructured solar cellsPhotoelectrochemical solar cell

- Q:The best authoritative research report, even if their YYThank you for the answer to the first floor, but I found the 2000 water heater Research Report, although a bit long, but you can also use

- Please look at the following article, how, I hope to help you.Along with the development of circular economy and energy-saving society, harmonious society, promote the development of renewable solar energy will further deepen and utilization, a huge space for development of the solar water heater manufacturers are increasing, the solar water heater manufacturers more and more in the current imperfect and immature market competition is intense, and even had a "bad money drives out good money" phenomenon, in the homogenization of the competition is a piece of the Red Sea, currently on the market on the one hand is the electric water heater, gas burner and solar water heaters on the other hand is a situation of tripartite confrontation, many district or city because of the "City" to the solar water heater, coupled with low barriers to entry and not mature consumer environment, frequent occurrence of water heater on the market collapsed, Water Leakage, no hot water phenomenon, making consumers. Solar water heater to break through the market, the need for in-depth market analysis, market segmentation, innovative marketing strategies, and then win the market.

- Q:Solar energy items in daily life

- The solar water heater, solar flashlight, solar micro kitchen, decoration, solar car

- Q:Solar products must be in the sun

- Energy (Solar), generally refers to the sun's radiant energy, passive use (photothermal conversion)

- Q:Good solar polymer or monocrystalline

- 1, the actual total power (load) and the use of time, should be reserved for the normal operation of the system;2, the local effective sunshine time, the proportion of rainy weather;3, the local meteorological data, such as sunshine time, weather disasters, storms and so on;4, the construction site must be open, in the installation of solar cells can not be tall buildings or other things blocking the sun;

- Q:Solar derived products The role of solar panels is to convert solar energy into electrical energy, the output of DC stored in the battery

- On the direct use of solar energy in humans is still at the primary stage, mainly solar collectors, solar water heating systems, solar heating, solar power, solar wireless monitoring etc.. Along with the development of modern enterprise system in our country's popularization and deepening development of enterprise informatization construction unceasingly thorough, safety and prevention work for enterprises using digital video technology has been combined with the development of solar energy technology represent the general trend, the launch of the real Winncam zero wiring for wireless monitoring solution. (solar wireless monitoring installation renderings)In the modern industrial park, the implementation of video surveillance system, the security department can realize all-weather real-time video monitoring in the industrial park at the entrance, the main road, office buildings, such as perimeter wall sites; the relevant departments can understand the situation, strengthen campus security management, improve work efficiency; the relevant departments can real-time understanding of each monitoring point the leading enterprises in the office; using a desktop computer, you can keep abreast of the real-time status of each monitoring point, handling emergencies, can also record multiple days ago, tracking and analysis, in addition to the establishment of local network monitoring system, but also to focus on remote video monitoring of branches. The actual production of Zhongcheng labor discipline inspection at any time Trw Corporation employees according to the actual needs of the park, some difficulties to take power, we use Solar power supply, with reference to the relevant international standards and national standards, combined with the company's experience in the Industrial Park monitoring and accumulated, the preparation of this zero wiring solar wireless monitoring technology program.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

TPt300 BackSheet of Hiuv for Solar Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m²

- Supply Capability:

- 2000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products