TP8-200A Rotary Packing Machine automatic

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 200 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Descriptions of TP8-200A Rotary Packing Machine

TP-TGXG-200 Bottle Capping Machine is an automatic capping machine to press and screw lids on bottles. It’s special designed for automatic packing line. Different to traditional intermittent type capping machine, this machine is a continuous capping type. Compared to intermittent capping, this machine is more efficient, pressing more tightly, and do less harm to the lids. Now it’s widely applied in food, pharmaceutical, chemical industries. It consists of two parts: capping part and lid feeding part. It works as following: Bottles coming(can joint with auto packing line)→Convey→Separate bottles in same distance→Lift lids→Put on lids→Screw and press lids→Collect bottles.

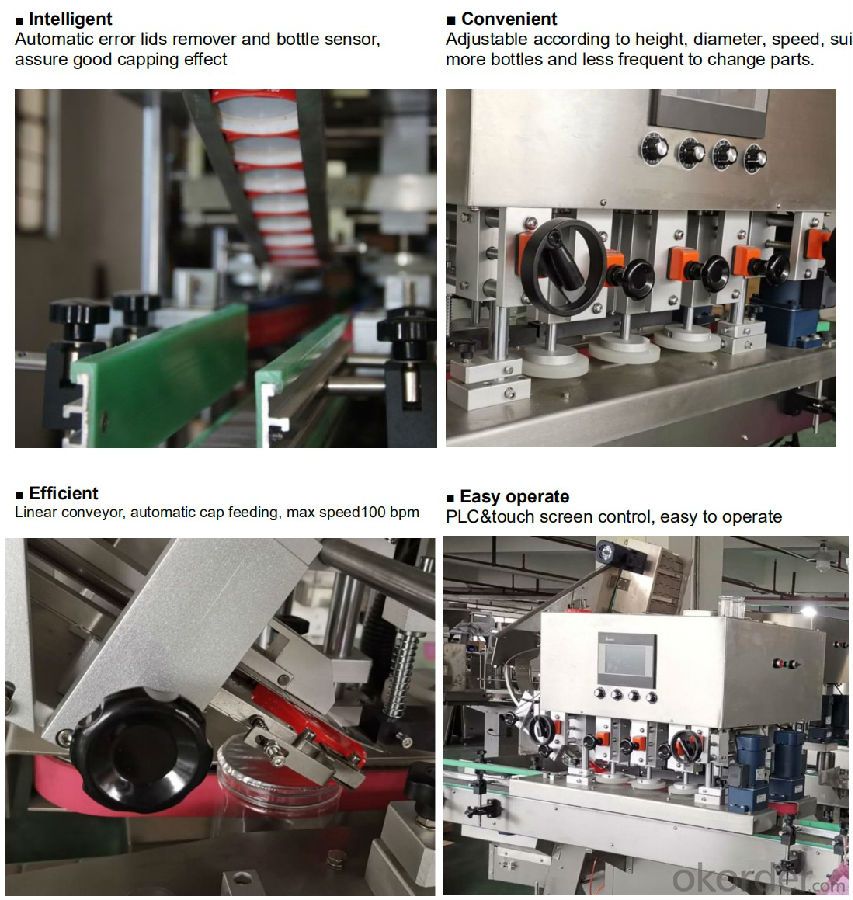

2. Main features

- PLC&touch screen control, easy to operate

- Easy to operate , Speed of conveying belt is adjustable to synchronous with whole system

- Stepped lifting device to feed in lids automatically

- Lid falling part can remove error lids away(by air blowing and weight measuring)

- All the contact parts with bottle and lids are made of material safety for food

- The belt to press the lids is inclined, so it can adjust the lid into the correct place and then pressing

- Machine body is made of SUS 304, meet GMP standard

- Optronic sensor to remove the bottles which are error capped (Option)

- Digital display screen to show the size of different bottle, which will be convenient for changing bottle(Option).

3. Technical parameters

| TP-TGXG-200 Bottle capping machine | |||

| Capacity | 50-120 bottles/min | Dimension | 2100*900*1800mm |

| Bottles diameter | φ22-120mm(customized according to requirement) | Bottles height | 60-280mm(customized according to requirement) |

| Lid size | φ15-120mm | Net weight | 350kg |

| Qualified rate | ≥99% | Power | 1300W |

| Material | Stainless Steel 304 | Voltage | 220V/50-60Hz ( or customized) |

4. Detailed photos

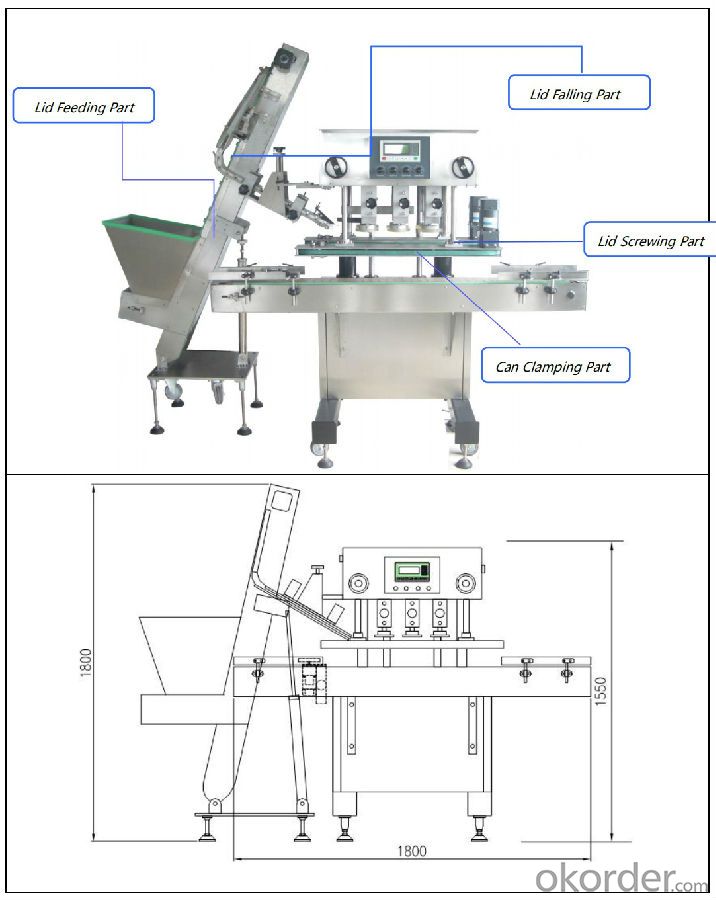

5. Structure & Drawing

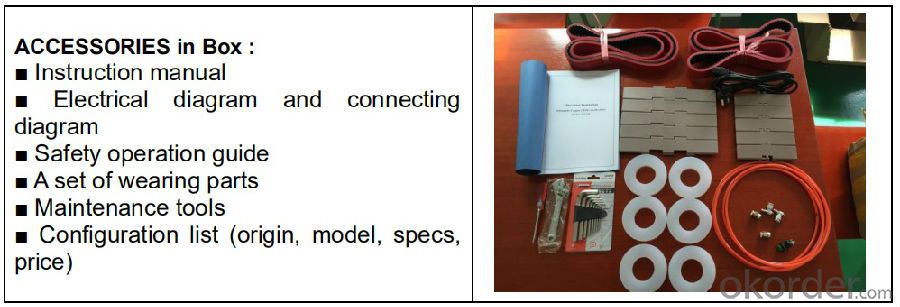

6. Shippment & Packaging

- Q:What is the delay time of the packer's cross sealing?

- The sealing time is how long the delay is when the sealing dies are joined together.

- Q:What is the general packing cost of beer beverage packaging?

- A privately owned enterprise production and processing, wholesale distribution, production of various types of complete packing machine, sealing machine, packing machine, vacuum machine, sealing machine, electromagnetic machine, packing machine, mushrooms should be material, full automatic filling machine, cuff type packing machine, sending spot

- Q:What are the structures of the packaging machinery?

- Is a professional engaged in "packaging machinery" research and development, production, sales as one of the multinational enterprise groups. It is the largest manufacturer of packaging machinery in china. Located in the Chinese science and Education City - Hefei, the geographical position is superior, the traffic condition is convenient, and the sale network extends the whole country. Is far from, with a group of the world's top machinery manufacturing R & D team, specializing in all walks of life packaging enterprises, for the efficient production of enterprises to provide power. It is a large enterprise that put forward the concept of packaging automation earlier in china. Brand with strong economic strength, first-class R & D level, advanced business philosophy and good brand service, more and more people all over the world are respected and trusted. The entire manufacturing process in full accordance with the highest standards of global manufacturing; at the same time according to the quality standard of global market development process, operating procedures and quality control system of production, all is "far Machinery" have reached world-class standards. "Far distance machinery" combines the characteristics of all kinds of products in China, such as packaging machinery, food packaging machines, two times packaging machines, powder packaging machines, particle packaging machines, liquid packaging machines, weighing machines, and so on.

- Q:The role of packaging equipment in packaging equipment

- Packaging is the necessary condition for products to enter the circulation field, and the main means of packaging is the use of packaging machinery. With the development of the times and the progress of technology, packaging equipment is playing a more and more important role in the field of packaging. The main functions of packaging equipment are as follows:

- Q:What does the mechanical equipment include?

- Track roller type rail flat car track car battery car nailThese are, want to know more, you can go to the network building equipment to see there

- Q:What kind of reducer is commonly used in packaging machinery?

- There are many kinds of reducers used. What kind of machines are they under?

- Q:Whether you can press paper plastic molding after PET

- Sure;Note cards must be coated with plastic oil;Can use blister sealing machine or high frequency plastic welding machine hot pressing;

- Q:The role of food packaging machinery

- (8) can promote the development of packaging machinery related industry is a comprehensive science which is related to many subjects, materials, process and equipment, electronics, electrical appliances, automatic control and other related disciplines, requires the simultaneous and coordinated development, the overall performance of any discipline problems will affect the packaging machinery. Therefore, the development of packaging machinery will effectively promote the progress of related disciplines. In addition, in order to meet the needs of high-speed packaging machinery packaging, the relevant front and rear processes are bound to adapt, and also promote the simultaneous development of related processes.Fig. 3 is a flow chart of liquid filling. With empty bottles of boxes stacked on pallets, by the conveyor belt to depalletizers, will remove the tray one by one, the box with the conveyor belt to the machine, remove the empty bottles from the box, empty by the conveying belt to the washing machine, after cleaning, and transported to the packing machine next to filled with beverage bottles into them. The empty bottles removed from the unloading machine are sent into the bottle washing machine by another conveyor belt for disinfection and cleaning. They are tested by the bottle inspection machine and conform to the cleaning standard and then enter the filling machine and capping machine. The beverage is bottled from a filling machine. Packed beverage bottle capping machine with the sealed and transported to the labeling machine labeling, (see pictures) with various beverage bottle filling line of the process is similar. But because of the different nature of beverage, the filling machine and capping machine are also different.

- Q:A & B two sets of packaging machines, at the same time packaging quality of 500 kilograms of goods

- 10 bags were randomly extracted from each of them, and the actual quality was measured as follows: (unit G)A: 501500503506504506, 500498497495B: 503504502498499501, 505497502499

- Q:What is the name of the paper used in packing machine parts and yellow?

- Vapor phase rust proof paper is coated with vapor phase corrosion inhibitor on the base of antirust base paper (surface like kraft paper, but with chloride ion and sulfate ion limit requirement)

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

TP8-200A Rotary Packing Machine automatic

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 200 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords