TP-PF Series Semi Automatic Powder Auger Filling Machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 500 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Description of TP-PF Series Semi Automatic Powder Auger Filling Machine

This type can do dosing and filling work. Due to the special professional design, so it is suitable to the fluidic or low-fluidity powder and small granules materials,It is widely used in food manufacturing, pharmaceutical manufacturing and other fields, Like instant coffee powder, formula milk powder, flour, proteins, flavors, sweetener, condiment, solid drinks, veterinary drugs, dextrose, pharmaceuticals, ,talcum powder, agriculture pesticide, dyestuff, and so on.2. Main features

- Lathing auger screw to guarantee the precise filling accuracy

- PLC control and touch screen display

- Servo motor drives screw to guarantee stable performance

- Split hopper could be washed easily without tools

- Can be setting to semi-auto filling by pedal switch or auto filling

- Full stainless steel 304 material

- weight feedback and proportion track to materials, which overcomes difficulties of filling weight changes due to materials' density change.

- Save 20 sets of formula inside the machine for later use

- Replacing the auger parts, different products ranging from fine powder to granule and different weight can be packed

- Multi language interface

3.Technical parameters

| Model | TP-PF-A10 | TP-PF-A11 | TP-PF-A11S | TP-PF-A14 | TP-PF-A14S |

| Control system | PLC & Touch Screen | PLC & Touch Screen | PLC & Touch Screen | ||

| Hopper | 11L | 25L | 50L | ||

| Packing weight | 1-50g | 1-500g | 10-5000g | ||

| Weight dosing | By auger | By auger | By load cell | By auger | By load cell |

| Weight feedback | By off-line scale ( in picture) | By off-line scale( in picture) | Online weight feed back | By off-line scale(in picture) | Online weight feedback |

| Packing accuracy | ≤100g, ≤±2% | ≤100g,≤±2%; 100-500g,≤±1% | ≤100g,≤±2%; 100-500g,≤±1%;≥500g,≤±0.5% | ||

| Filling speed | 40-120 times per minute | 40-120 times per minute | 40-120 times per minute | ||

| Power supply | 3P AC208-415V 50/60HZ | 3P AC208-415V 50/60Hz | 3P AC208-415V 50/60Hz | ||

| Total power | 0.84 KW | 0.93KW | 1.4KW | ||

| Total weight | 90kg | 160kg | 260kg | ||

| Overall dimensions | 590*560*1070mm | 800*790*1900mm | 1140*970*2200mm | ||

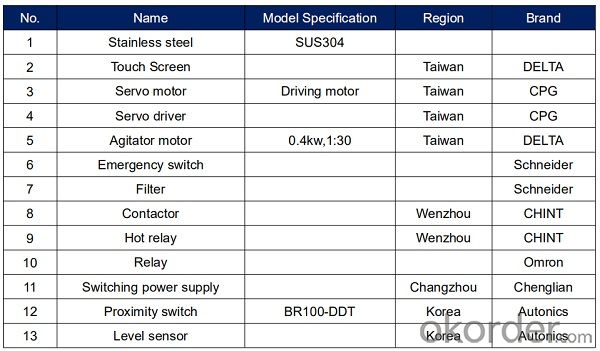

4. Configuration list

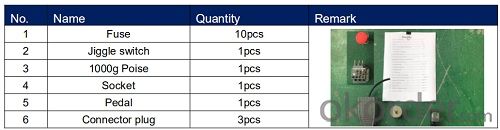

Accessories

Tools box

5. Detail images of the machine

-Level sensor----tuning fork type level sensor, P+F brand, it is more suitable for all kinds of materials, especially dusty materials.

- Feed inlet & air outlet----feed inlet with radian to reduce impact for hopper; Air outlet with quick connection type, more convenient installation and dis- assembly.

-screw way to fix metering auger in the hopper----It will not make material stock and easy for cleaning.

-Height adjust handwheel for filling nozzle----It is suitable for filling into bottles/bags with different height.

6. Remark

- One year warranty, life-long service

- Provide accessory parts in favorable price

- Update configuration and program regularly

- Q:What are the main plastic forming processes?

- The main equipment used for molding compression is to press and mold. The most used hydraulic press is self support hydraulic press. The tonnage varies from tens to hundreds of tons. There is a lower press and an upper press. The die used for compression molding is called pressing die. It is divided into three kinds: overflow mould, half overflow mould, no overflow mold.The main advantage of compression molding is that it can be molded into larger flat products and can be produced in large quantities. Its disadvantage is long production cycle and low efficiency.2. lamination forming. A method of combining two or more layers of material of the same or different material by heating and pressurizing with or without a binder.A layer of floating hot pressing plate is arranged between the movable plate and the fixed plate of the press.The reinforcing materials used in laminated forming are cotton cloth, glass cloth, paper and asbestos cloth. The resins are phenolic, epoxy, unsaturated polyester, and some thermoplastic resins.

- Q:Food, equipment, tools, containers, packaging materials, etc. shall comply with food safety standards or requirements

- Hygienic standard for polyethylene terephthalate resin for GB 13114 food containers and packaging materialsGB, 13113-1991. Hygienic standard for polyethylene terephthalate molded articles for food containers and packaging materials

- Q:What's the best place to use the pillow type packing machine?

- In the early communication can be reflected, and sometimes non-standard customized to see the level of Technology

- Q:What are the packing machines?

- Heat shrink packaging machine, mask packaging machine, pillow type packaging machine, food packaging machine, I suggest you can go to see

- Q:What is the general packing cost of beer beverage packaging?

- A privately owned enterprise production and processing, wholesale distribution, production of various types of complete packing machine, sealing machine, packing machine, vacuum machine, sealing machine, electromagnetic machine, packing machine, mushrooms should be material, full automatic filling machine, cuff type packing machine, sending spot

- Q:What's the fastest packing machine?

- Depending on the characteristics of your material, the speed is adjustable!

- Q:Whether you can press paper plastic molding after PET

- Sure;Note cards must be coated with plastic oil;But to use the hot pressing machine there is to do bakelite mold. Our company specializing in the production of blister, in addition to help customers hot packaging, directly to the finished products to customers

- Q:The role of food packaging machinery

- 3) to achieve manual packaging can not achieve the operation, some packaging operations, such as vacuum packaging, inflatable packaging, body packing, isobaric filling, etc., are manual packaging can not be achieved, can only be achieved by mechanical packaging.(4) can reduce labor intensity, improve the working conditions of the labor intensity of manual packaging, such as volume, weight heavy manual packaging products, both the consumption of physical strength, and safety; and for small and light products, due to high frequency, easy to make the action monotonous, worker occupation disease. Carton folding machine(5) in favor of labor protection for some serious impact on health products, such as serious dust, toxic products, irritating, radioactive products, manual packaging is a health hazard, and packaging machinery can be avoided, and can effectively protect the environment from being polluted.(6) it can reduce the cost of packing and save the storage and transportation expenses. It can reduce the volume and reduce the packing cost by compressing and packing the loose products, such as cotton, tobacco leaf, silk and hemp. At the same time, due to the reduction of large volume, in order to save storage capacity, reduce storage costs, is conducive to the transport.(7) ensure product health of certain products, such as food and drug packaging, according to the health law is not allowed to use manual packaging, because it will pollute the products and packaging machinery to avoid direct contact with the staff of food and medicine, to ensure the quality of health.

- Q:What is the price of a small jujube packing machine?

- What is the price of a small jujube packing machine?

- Q:Ask a mechanical problem, the waste film recycling in the packaging machinery is a new film packaging, after cutting, then use the roller to recycle the waste film. Encounter a

- It is recommended not to check the cursor, if the speed is stable, with the amount of speed (recommended to detect the angular speed of the drum) to detect, a closer speed will be smaller, you can do the implementation of the operation. If the speed is unstable, you can only use the scale. But the 2 one is marked out. The beginning and the end. A colleague detects the difference in velocity between the 2 displacements. The difference in speed means that the film is stretched and the excessive velocity is stopped directly, which means that the film has been stretched

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

TP-PF Series Semi Automatic Powder Auger Filling Machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 500 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords