TP-A Series Multihead Weigher food usage

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 200 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. General descriptions of the TP-A Series Multihead Weigher

It is suitable for weighing leisure foods such as candy, seeds, jelly, pet foods, puffy foods, pistachio, peanuts, nuts, raisins etc. and big shell nuts, hardwares, dried fruits, frozen foods, snack foods, meatballs and so on.

2.Mains Features

- Adopt high precision and high accurate loadcell of famous brand, resolution is improved up to 2 decimal;

- Program recovery function can reduce operation failures and support multi-segment weight calibration;

- No products auto pause function can improve weighing stability and accuracy;

- 100 programs capacity can meet various weighing requirements and user-friendly help menu contributes to easy operation;

- Linear amplitude can be adjusted independently in the running;

- Many languages available for global markets.

- Sanitation with 304S/S construction ;

- Rigid design for vibrator and feed pan make feeding strictly correct ;

- Quick release design for all the contact parts

- Grand new modular control system .

- Adopt stepless vibrating feeding system to make products flow more fluently .

- Make mix different products weighing at one discharge .

- Parameter can be freely adjusted according to production .

3. Technical parameters

| Model | TP-A10 | TP-A14 |

| Weighing range | 10-1000g | 10-1500g |

| Accuracy | X(0.5) | X(0.5) |

| Max speed | 65P/M | 120P/M |

| Hopper volume | 1.6/2.5L | |

| Control panel | 7" Touch screen | |

| Options | Dimple plate/Timing Hopper/Printer/Reject Device | |

| Driving system | Step motor | |

| Power Requirement | 220V/1000W/ 50/60Hz / 10A | 220V/1500W/ 50/60Hz / 10A |

| Packing dimension(mm) | 1620(L)*1100(W)*1110(H) | 1700(L)*1100(W)*1265(H) |

| Gross weight | 380kg | 490kg |

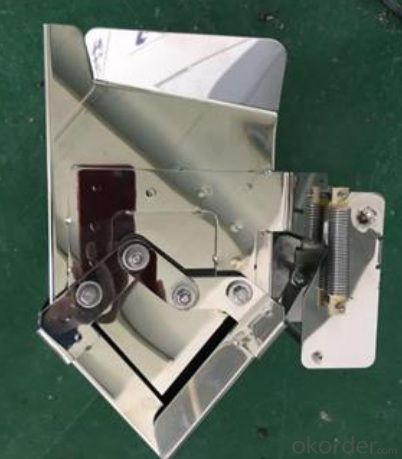

4. Detailed photos

-Grand new modular control system, high stability, high accuracy, can be accurate to 0.1g.

- Multi languages on touch screen for choice

- Weighing hopper 4.5L SUS material, full mirror polished, it meets food grade, and very easy for cleaning

-Linear vibrator

1) SUS material, full mirror polished, it meets food grade, and very easy for cleaning.

2) Quick release design, easy for fixing and cleaning.

5. Packages and delivery

6. Remarks

- TWO YEAR warranty, ENGINE THREE YEARS warranty, life-long service

(Warranty service will be honored if the damage is not caused by human or improper operation)

- Provide accessory parts in favorable price

- Update configuration and program regularly

- Q:What's the best place to use the pillow type packing machine?

- Suggest that manufacturers can find communication, there is no technical strength,

- Q:What are the structures of the packaging machinery?

- Is a company engaged in outsourcing clients, packaging, processing, packaging equipment, leasing, services, sales in one of the specialized companiesSales of second-hand packing equipment according to the customer's product features and requirements. Reduce customer purchasing costsAccording to the customer's product characteristics and requirements. Select the best packaging equipment for customers, reduce customer purchasing costsPackaging equipment spare parts sales and maintenance services

- Q:What does the mechanical equipment include?

- Track roller type rail flat car track car battery car nailThese are, want to know more, you can go to the network building equipment to see there

- Q:What kind of reducer is commonly used in packaging machinery?

- There are many kinds of packing equipment, such as food packing, filling, quantitative packing, back channel packing and so on

- Q:Predecessors please point out: what is the future of packaging machinery industry?

- China's packaging machinery and equipment manufacturing enterprises should seize this opportunity.The overall upgrading of packaging machinery equipment is the general trend of the development of packaging machinery in China and the world. The main features of the renewal is: a large number of transplanted with civilian and military industries all modern high precision technology and electronic technology, microelectronic technology, edge technology, fuzzy technology, accelerate the further improve the reliability, safety, no work of the level of automation of packaging machinery and equipment and production line. Intelligence will move into the field of packaging machinery, equipment and production lines.

- Q:Is there anyone who knows what groups of users of packaging machinery are in general?

- This is really not sure, it can be said that any group, as long as the packaging products are required to use packaging machinery. Most of the products are now in need of packing. So it can be said that any group.

- Q:Vacuum packing machine for cooked food: can whole chicken, whole goose and whole duck be packed?

- Sometimes, this wine packaging PigHead, with different types of vacuum packaging machine

- Q:What is the price of a small jujube packing machine?

- What is the price of a small jujube packing machine?

- Q:What is the design basis of automated packaging?! Just for today!

- Greatly improve the degree of automation of process flowA few years ago, automation technology accounted for only 30% of the design of packaging machinery, now has accounted for more than 50%, a large number of micro computer design and mechanical and electrical integration control. To improve the packaging machinery automation, one is to increase productivity; the two is to improve the flexibility and agility equipment; three is to improve the ability of packaging machinery to complete the complex action, namely the manipulator to complete the packaging process. Such as chocolate packaging has been achieved, with mechanical hand instead of the original manual. Automatic design of packaging machinery has the following two main characteristics:

- Q:Energy saving reform of packaging machine

- Due to the adoption of variable frequency speed regulation, the chain drive is greatly reduced, the stability and reliability of the operation of the machine are improved, and the noise of the machine operation is reduced. It guarantees the high efficiency, low loss and automatic detection of the packaging machine. It has both a beautiful and fashionable appearance, and a healthy and smart mind.Although the transmission system used in food packaging machine is relatively simple, it has higher requirements for the dynamic performance of the transmission. The system requires fast dynamic follow-up performance and high stability speed accuracy. Therefore, we must consider the dynamic technical indicators of inverters, and select high-performance inverter to meet the requirements.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

TP-A Series Multihead Weigher food usage

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 200 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords