Tower Cranes TC7135 ConstructionEquipment Building Machinery Sales

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Tower Crane TC6024 Details:

Minimum Order Quantity: 1unit Unit: unit Loading Port: China main Port

Supply Capability: 5unit/month Payment Terms: T/T or L/C

Tower Crane TC6024 Description:

1.CMAX Tower Crane TC6024 is one of the main product of CNBM company, which have competitive price and excellent quality, suitable for all kinds of construction project and can work under all kinds of work condition.

2. Tower Crane TC6024 can adopts standard section hydraulic lifting and connecting, and can decide the crane height according to the actual height of the building, and at the same time the lifting capacity will not be affected.

3. Tower Crane TC6024has high working speed, good speed-adjusting performance, steady operation and high efficiency. Three-speed motor and mono-speed ratio decelerator are applied in the lifting struction, which enables heavy load low speed and light load high speed.

4.Tower Crane TC6024 has complete set of safety devices, which can guarantee the safe and high efficienct operation of the equipment. The machine is equipped with lifting height limiter, dolly range-change limiter, moment limiter,weightlimiter,circumgyrating limiter,and so on.

5.Tower Crane TC6024 has scientific layout and beautiful appearance. The operator's room is set independently on one side, with good vision field. It creates a good working environment for the operato.

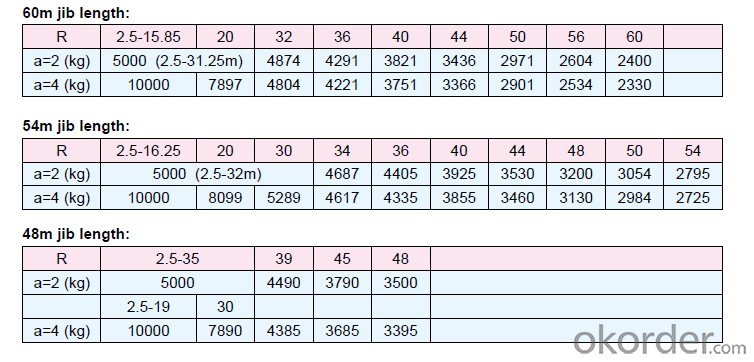

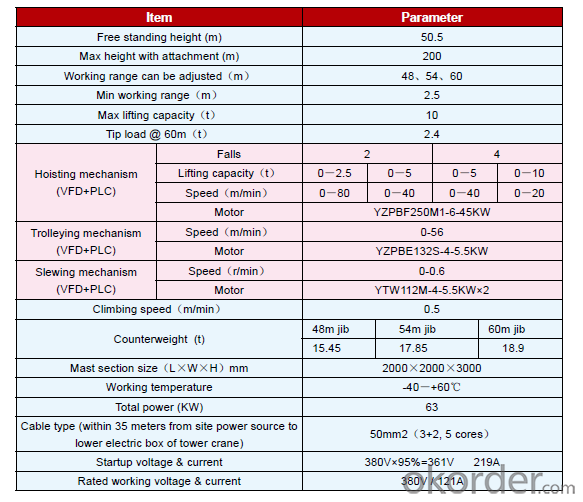

Tower Crane TC6024 Parameter:

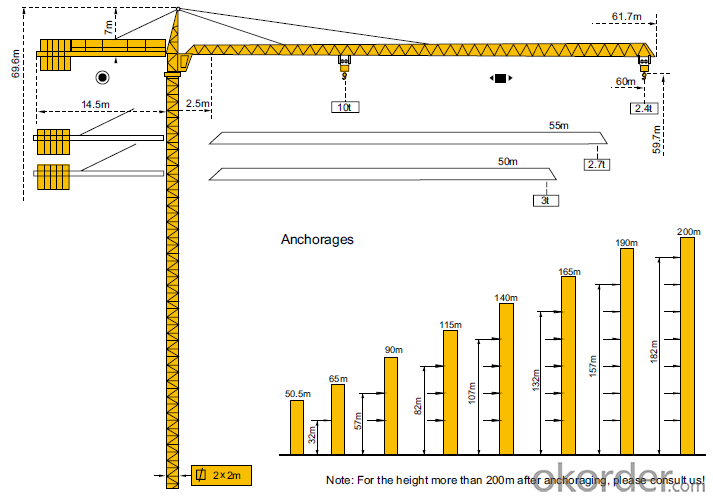

Max. working range 60m, tip lifting weight 2.4T and Max. lifting weight 10T.

Hoisting mechanism fitted with three speed motor, stable braking and less shock when shifting.

Trolleying mechanism can provide two operation speeds.

Free standing height (m) 50.5

Max height with attachment (m) 200

Working range can be adjusted (m) 48、54、60

Min working range (m) 2.5

Max lifting capacity (t) 10

Tip load @ 50m (t) 2.4

Tower Crane TC6024 Packaging & Delivery:

40HQ container

20~25days after deposit

Tower Crane TC024 Diagram:

\ \

\

Tower Crane TC6024 Technical Sheet:

Tower Crane TC6024 FAQ:

1.What is tower crane?

Tower crane is a modern form of balance crane that consist of the same basic parts. Fixed to the ground on a concrete foundation (and sometimes attached to the sides of structures as well), tower cranes often give the best combination of height and lifting capacity and are used in the construction site.

2. What is the meaning of the tower crane’s code?

Take Tower Crane TC6024 for example, the first two letters “TC” means Tower Crane, “60”means jib length is 60 meter, and the last two letter “24” means the tip load is :2.4 ton.

3. What is the principal to quote the right tower crane to the client?

First, we need to know clients’ requirements,for example, max lifting capacity, height, tip load and jib length.. Second, we need to know what the foundation requirement from the client is and Third if there are special needs. CNBM could suggest proposal according to clear data provided by the clients.

- Q:What is equipment manufacturing and machinery manufacturing? What's the difference between them?

- Equipment manufacturing, also known as equipment industry, mainly refers to the capital goods manufacturing industry, is to meet the needs of the development of the national economy departments and national security needs and manufacture all kinds of technical equipment industry collectively. According to the national economy sector, its range of products including investment manufactured goods machinery electronics and ordnance industry, belonging to the metal products industry, general equipment manufacturing industry, special equipment manufacturing, transportation equipment manufacturing, electrical equipment and equipment manufacturing industry, electronics and communications equipment manufacturing, instrumentation and cultural office the equipment manufacturing industry in the 7 major categories of 185 kinds.

- Q:How are buildings, installations and materials divided?

- Equipment generally includes the following: (1) all kinds of equipment and the equipment with the arrival of accessories, spare parts and equipment attached to the body made of ladders, platforms, railings and pipes. (2) various gauges, instruments and automatic control devices, experimental instruments, instruments and meters in the main part of the equipment. (3) components of equipment, such as oils, chemicals, etc. attached to the equipment body.

- Q:What are the mixing arms of the concrete mixer?

- Mixing arm concrete mixer is a component of the mixing arm itself and divided into lateral mixing arm (positive and negative points), stirring arm (also have positive and negative points), stirring arm below is the bearing seat connected, connected with 4 sets of high strength bolts with stirring arm. The top is equipped with wear-resistant mixing blades, connecting with mixing blades, high-strength bolts 2 sets. In addition, some manufacturers have designed mixing side bonded shaft swivel, is installed in the interval between the stirring arm fixed and rotated in two ways.

- Q:What is the difference and connection between equipment manufacturing and machine building?

- When our company went to the training center of the Department of industrial engineering of Tsinghua University, the professor of Qinghua University told us about it. Equipment manufacturing industry is a general term for the equipment provided for the national economy and national security

- Q:What are the principles, performances and uses of the commonly used construction machinery equipment?

- 2.: Principle: loader loader work, powered by a flywheel of the diesel engine to the hydraulic torque converter, the torque converter will drive to the gearbox, and before and after the output flange of the gearbox, the power output of the gearbox after the transmission shaft are respectively transmitted to the front and back drive axle to drive the wheels forward. Performance: 1) Central articulated frame, turning radius is small, flexible and convenient operation in narrow space; 2) using hydraulic mechanical transmission, according to the size of the external resistance and automatic stepless speed change, which can make full use of engine power, and improve the maneuverability, simplifies the loader operation. Is to protect the transmission parts and engine; 3) adopts full hydraulic steering, power shift transmission, hydraulic or flexible manipulation, portable and flexible machine; 4) stable and reliable operation; wide use of low-pressure off-road tires, rear axle swing, with good cross-country performance and through the performance by 5); gas cap oil disc brake system and brake foot up, emergency braking system, the braking performance is safe and reliable; 6) with advanced structure and bright cab. The air conditioning system operates more comfortably. Uses: loaders are mainly used for shovel, loading, unloading, transport of soil and stone a kind of bulk materials, rock and hard soil can also be slightly shovel operations.

- Q:What measures can effectively reduce the construction accident rate?

- Hefei construction workers training _ eliminate dangerous source: eliminate the risk source of the system can fundamentally prevent accidents. But an important point of system safety is that it is impossible to completely eliminate all sources of danger and that people can only selectively eliminate several specific sources of danger. Generally speaking, when the risk of a dangerous source is higher, we should first consider whether we can take measures to eliminate it. A dangerous source can be completely eliminated by selecting the proper production process, technology, equipment, reasonable design, structural form or suitable raw material. For example: instead of the power system with pneumatic or hydraulic system, to prevent the occurrence of electrical accidents; instead of compressed air system for hydraulic system, to avoid the pressure vessel, pipeline rupture caused by shock wave; with incombustible materials instead of combustible materials, to prevent the occurrence of fire. It should be noted that sometimes measures are taken to eliminate certain sources of danger, but new sources of danger may be brought about. For example, an electric pneumatic system instead of a power system can prevent electrical accidents, but a physical explosion accident may occur in the compressed air system.

- Q:The building electrical iron pipe and the pipe line fixing member connected to what is called, what is called the iron pipe and the 86 fixed part of tin

- Pipe or direct protection, construction of special operation personnel of construction electrician training materials, focus on the "construction of special operations personnel management regulations", "construction of special operations personnel safety technology assessment program (Trial)", "construction of special operations personnel safety operation skills examination standard (Trial)" and other relevant provisions safety, technical knowledge and skills to master for construction electricians were explained, the book has 10 chapters, including: basic knowledge, common low-voltage electrical appliances and Motor City, power supply and grounding earthing protection system.

- Q:How are the machine parts stacked?

- Then there is a point to note, that is, from there to get used, must be put back where, so that will be organized, all things are owned by you, it will not mess.

- Q:What are the sectors of machine building and parts processing?

- 1., industry generally refers to its production of similar products, or with the same process, or to provide similar labor services division of economic activities, categories.

- Q:Definition of large mechanical equipment?

- The hoisting machinery used in bridge construction can be divided into three categories: light and small lifting equipment, bridge type crane and boom type crane. Light and small lifting equipment, such as jacks, hoists, winches, etc.. Bridge type lifting machinery, such as beam cranes, Longmen cranes and so on. Boom type cranes, such as stationary slewing cranes, tower cranes, truck cranes, tires, crawler cranes, etc..

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Tower Cranes TC7135 ConstructionEquipment Building Machinery Sales

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords