Tower Cranes TC5610 Construction Equipment Building Machinery

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Tower Crane TC6016 Details:

Minimum Order Quantity: 1unit Unit: unit Loading Port: China main Port

Supply Capability: 5unit/month Payment Terms: T/T or L/C

Tower Crane TC6016 Description:

1.CMAX Tower Crane TC6016 is one of the main product of CNBM company, which have competitive price and excellent quality, suitable for all kinds of construction project and can work under all kinds of work condition.

2. Tower Crane TC6016 can adopts standard section hydraulic lifting and connecting, and can decide the crane height according to the actual height of the building, and at the same time the lifting capacity will not be affected.

3. Tower Crane TC6016 has high working speed, good speed-adjusting performance, steady operation and high efficiency. Three-speed motor and mono-speed ratio decelerator are applied in the lifting struction, which enables heavy load low speed and light load high speed.

4.Tower Crane TC6016 has complete set of safety devices, which can guarantee the safe and high efficienct operation of the equipment. The machine is equipped with lifting height limiter, dolly range-change limiter, moment limiter,weightlimiter,circumgyrating limiter,and so on.

5.Tower Crane TC6016 has scientific layout and beautiful appearance. The operator's room is set independently on one side, with good vision field. It creates a good working environment for the operato.

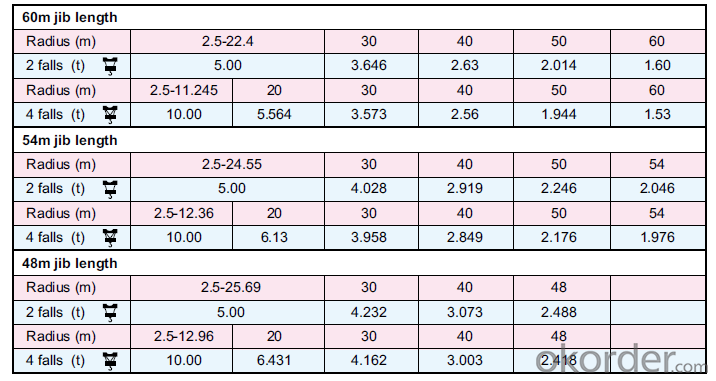

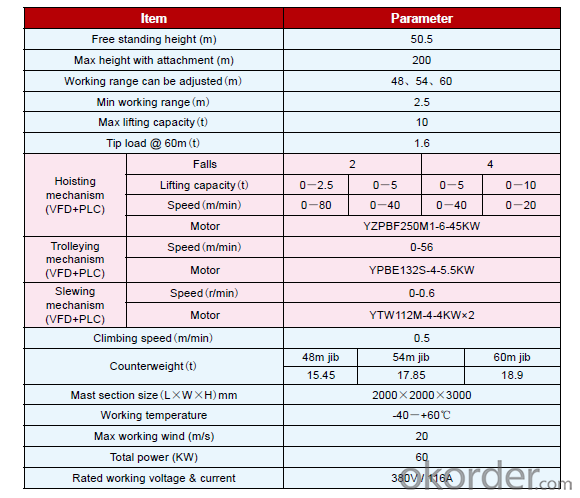

Tower Crane TC6016 Parameter:

Max. working range 60m, tip lifting weight 1.6T and Max. lifting weight 10T.

Hoisting mechanism fitted with three speed motor, stable braking and less shock when shifting.

Trolleying mechanism can provide two operation speeds.

Free standing height (m) 50.5

Max height with attachment (m) 200

Working range can be adjusted (m) 48、54、60

Min working range (m) 2.5

Max lifting capacity (t) 10

Tip load @ 50m (t) 1.6

Tower Crane TC6016 Packaging & Delivery:

40HQ container

20~25days after deposit

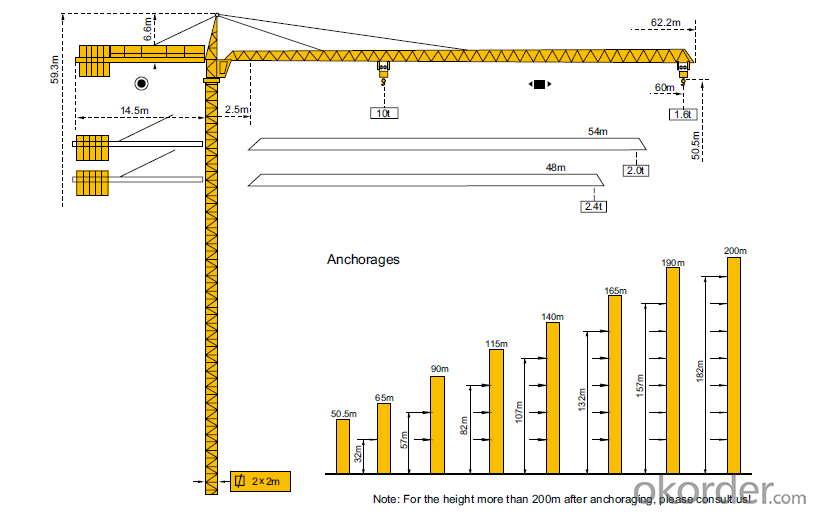

Tower Crane TC6016 Diagram:

Tower Crane TC6016 Technical Sheet:

Tower Crane TC6016 FAQ:

1.What is tower crane?

Tower crane is a modern form of balance crane that consist of the same basic parts. Fixed to the ground on a concrete foundation (and sometimes attached to the sides of structures as well), tower cranes often give the best combination of height and lifting capacity and are used in the construction site.

2. What is the meaning of the tower crane’s code?

Take Tower Crane TC6016 for example, the first two letters “TC” means Tower Crane, “60”means jib length is 60 meter, and the last two letter “16” means the tip load is :1.6 ton.

3. What is the principal to quote the right tower crane to the client?

First, we need to know clients’ requirements,for example, max lifting capacity, height, tip load and jib length.. Second, we need to know what the foundation requirement from the client is and Third if there are special needs. CNBM could suggest proposal according to clear data provided by the clients.

- Q:What is equipment manufacturing and machinery manufacturing? What's the difference between them?

- Major technical equipment refers to the technical difficulty in equipment manufacturing, complete and strong, is of great significance, has a significant impact on the national economy need to be beneficial to the people's livelihood, complete sets of major technical equipment organizations across sectors, industries and regions to complete.

- Q:Where was the construction machinery conference held in 2015?

- Co organizer: BMW (Chinese) Engineering Machinery Company Limited, Shandong Lingong Construction Machinery Co, Limited by Share Ltd, Shantui construction machinery Futian leiwo international heavy industry Limited by Share Ltd, Shandong Chang Linzhu Machinery Group Limited by Share Ltd, Shandong rhinos Engineering Machinery Company Limited, Beijing Tianshun Hydraulic Technology Co., Ltd. Ji'nan the Great Wall Andy Machinery Co. Ltd., Langfang Deji machinery Polytron Technologies Inc, Tai'an Dongyue Heavy Industry Co. Ltd.

- Q:How do the welding parts in the welding drawings of the machine parts indicate the technical requirements of the drawings?

- The whole circle of the triangle is welded as an angle weld, and the other is the outer circle with the same diameter as the two, so the butt joint is better to open the groove. Welding, for V type welding seam, and, technical requirements are generally, welding firm, no defects, welding smooth grinding, cleaning welding slag splash

- Q:What are the principles, performances and uses of the commonly used construction machinery equipment?

- 1.: concrete pump principle: concrete pump driven by motor pump system, the conveying capacity of constant power control of hydraulic system of concrete pump automatic control, manual control can also be used to select the concrete delivery volume. Performance: 1. using the hydraulic system of double pump double open circuit, the main pump valve swing circuit and S circuit are separate for fault diagnosis and removal; 2. pumping hydraulic circuit adopts the main valve pilot pressure control; 3. hydraulic system has safe relief protection, while the main pumping system overpressure, oil pump automatic pressure cutting off; 4. switching circuit with constant voltage supply with the energy storage device, so as to guarantee reliable swayingforce large and have the advantages of energy saving effect; 5. pumps and valves are used continuously, the world famous brand is more reasonable and more reliable and easily realized commodity concrete transport quantity adjustment; 6. hydraulic pipeline with cone seal pipe joint sealing material; 7. pumping circuit adopts a valve block mode of high and low voltage switch, convenient, no leakage; 8. with oil and oil filter technology, foreign body into the hydraulic system. Further improve the hydraulic system reliability and component life; 9. hydraulic hose hose. Use: widely used in commercial concrete demand for large, high grade and strict quality requirements, long conveying distance of high-rise buildings, municipal construction, electric power, energy, transportation and other civil and industrial buildings, especially the construction of the narrow space more show its true colour of a hero.

- Q:What is the use of spare parts prices in Chinese market by foreign companies?

- You might be gathering information for him. You have no data for one person, if there are several people? They can analyze a lot of things through big data. You can't find out, you're OK. Once you find out, your whole life is over.

- Q:What measures can effectively reduce the construction accident rate?

- Hefei construction workers training _ eliminate dangerous source: eliminate the risk source of the system can fundamentally prevent accidents. But an important point of system safety is that it is impossible to completely eliminate all sources of danger and that people can only selectively eliminate several specific sources of danger. Generally speaking, when the risk of a dangerous source is higher, we should first consider whether we can take measures to eliminate it. A dangerous source can be completely eliminated by selecting the proper production process, technology, equipment, reasonable design, structural form or suitable raw material. For example: instead of the power system with pneumatic or hydraulic system, to prevent the occurrence of electrical accidents; instead of compressed air system for hydraulic system, to avoid the pressure vessel, pipeline rupture caused by shock wave; with incombustible materials instead of combustible materials, to prevent the occurrence of fire. It should be noted that sometimes measures are taken to eliminate certain sources of danger, but new sources of danger may be brought about. For example, an electric pneumatic system instead of a power system can prevent electrical accidents, but a physical explosion accident may occur in the compressed air system.

- Q:Construction machinery production need to deal with what documents?

- At all levels of production safety responsibility system, mainly refers to: the legal representative of the safe production responsibility system; the responsible person in charge of safety production safety responsibility system; the technical director (Chief Engineer) production safety responsibility system; the safety department (Department) Changan production responsibility system; responsibility for production safety, the project manager; specifically (and) post safety responsibility system for production safety; construction technician (technician), safety production responsibility system; 8 class (Group) Changan production responsibility system; workers, production safety responsibility system. Departments responsible for production safety system, mainly in accordance with the functions of enterprises set up departments, the corresponding formulation of the responsibility system for safety in production.

- Q:The building electrical iron pipe and the pipe line fixing member connected to what is called, what is called the iron pipe and the 86 fixed part of tin

- The distribution of the construction site, construction machinery and electric hand-held electric tools, lighting, construction site construction site: risk factors and lightning protection, the construction site of common electrical tools and instruments, the construction site of the electricity management, common electrical fault, accidents and accident cases.

- Q:How are the machine parts stacked?

- Classification ah! Put small pieces of different sizes and functions into boxes and attach labels; larger items can be placed outside in a certain order (for example, function, length, value, etc.)

- Q:What are the mechanical drawing software?

- The 3D map only contact with SolidWords and Pro/E, Pro/E is better than Solidwords in general, but Solidwords is very simple to use, see Help tutorials you can learn to draw a three-dimensional map is not particularly complex easily to estimate a few days is enough. But any one of the two kinds of software, want to do not understand the words, expert advice is not really easy. UG and MasterCAM haven't touched much, but I've heard that it's suitable for processing stereogram.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Tower Cranes TC5610 Construction Equipment Building Machinery

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords