Tower Crane TC7021 QTZ250 New Mast Section

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

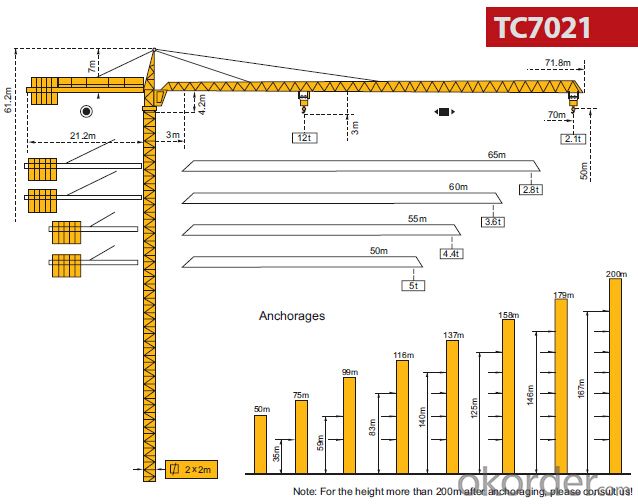

Detail of Tower Crane

Feature:Tower Crane Condition:New Model Number:TC7021(QTZ250) Place of Origin: China (Mainland) Brand Name: CMAX Certification: ISO,CE Warranty: 1 Year Application:Building,Construction,Industrial

Main Features of Tower Crane

1) This series of tower cranes, ranging from QTZ40 to QTZ400 has a horizontal jib frame, a jib-trolley radius-changing mechanism and a hydraulic self-raising mechanism. It is original in design, reliable in operation and satisfactory in shape. Equipped with all necessary safety devices, these cranes show a good speed-control capacity, satisfactory operating stability and high work efficiency. They can be widely used for the construction of high-rise hotels, residential buildings, high-rise industrial buildings, large-span factory buildings and tower-like buildings like tall chimneys.

2) It has high working speed, good speed-adjusting performance, steady operation and high efficiency. Three-speed motor and mono-speed ratio decelerator are applied in the lifting struction, which enables heavy load low speed and light load high speed. 3)The range-change structure drives the trolley moving on the horizontal crang jib, with good positioning performance. Planet gear decelerator is applied in the circumgyrating structure, together with moment-limiting hydraulic coupler, which can relize high load capacity, steady starting and reliable operation.

4) The crane has complete set of safety devices, which can guarantee the safe and high efficienct operation. The crane is equipped with lifting height limiter, trolley ranging limiter, moment limiter, weight limiter etc..

5)The cranehas scientific layout and handsome appearance. The drivers cab is set independently on one side, with good vision field. It creates a good working environment for the operator.

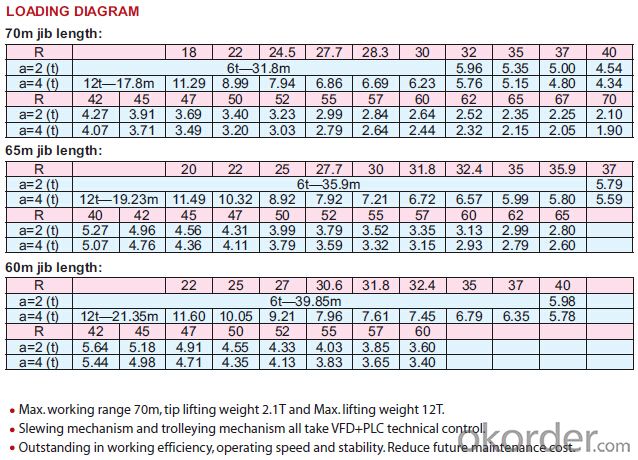

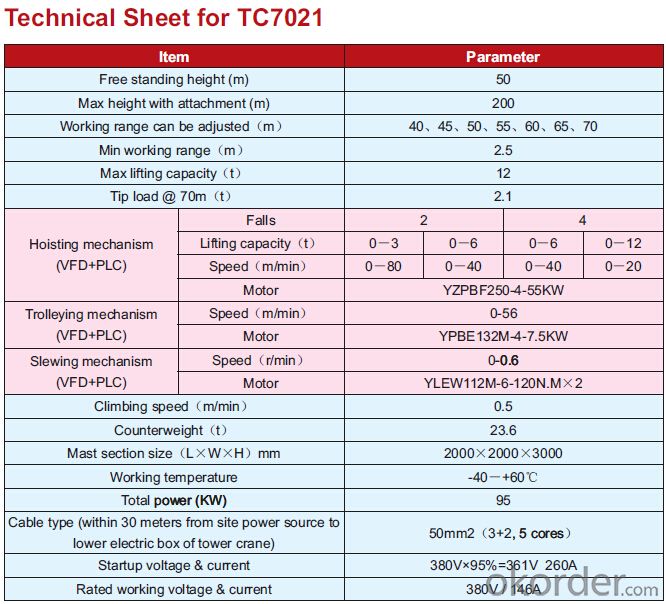

Specification of Tower Crane

Images of Tower Crane

FAQ about Tower Crane

Q: What serice you could provide? A: Providing timely delivery, standby engineers are ready to slove any of your problem Providing all-embraced warranty of products quality, worksite installation guidance Providing ample spare parts and training of operation and maintenance Engineers have more than 20 years' experience in tower crane, ready to solve any of your problems.

Q: What kind of steel used for tower crane ? A: Normally, as for the main force bearing steel structure, Q345B is adopted; as for the assistance force bearing steel structure Q235B is adopted. All of the raw material is outsourced from qualified steel factory in China.

Q: What about our tower crane warranty? A: Usually there is one-year quality warranty including main electronic parts (not including consumable parts). There are consumable spare parts together with whole machine and normally they are enough for one year.

Q: What is 3 main mechanism of the tower crane ? A: there are trolleying mechanism/ slewing mechanism/ hoisting mechanism.

Q: Can you equip with light on tower crane jib, monitor, remote control and anemometer? A: Sure. All of these could be provided with extra cost upon the clients' requirements. But according to general practice, remote control is not suggested because most of the operator feedback operation in the cabin will provide a wide working view. | |||||

| (0) | |||||

- Q:I saw a picture of a oragami crane ring that was made out of money on a website but it diddint have any instructions on how to make it. I can already make the regular ring, but i would really like to try to make the crane ring does anyone know of any website that has instructions on how to make it??

- I okorder /

- Q:If a crane fly loses a leg will he be okay? Is it painful for him or do they just 'release' them like a lizard can release it's tail?

- Chances are, it won't be O.K. Some spiders can release their legs, but only if given fair warning (a gentle tug). If the crane fly lost his leg violently, he will probably die from the injury. Whether or not the injury kills him, he will, of course, be more vulnerable to predators. Not to be morbid or cold, because I really do love animals, and hate to see harm come even to the under appreciated invertebrates, but the Crane fly usually only lives a couple of days, so as long as he mated, his job on earth was finished anyway.

- Q:can anyone tell me the principle under which a GANTRY CRANE works..........Suggest me some websites which gives details about the working of gantry crane ....please help me......

- This okorder /

- Q:My best friend is going to live in Japan for about a year soon, and I want to send him a birthday present while he's there. A lot of the places I've looked say it's common to make 1000 cranes for people as a wedding present, or in preparation for your own wedding so I'm not sure this is an appropriate gift -___- Also, I have no idea how I would ship them to him...

- One idea would be to send one crane that you've made using airmail paper. Write your wish for your friend tell him that you have 999 more cranes waiting for him to return home again.

- Q:quick answer or i'll delete it!

- Well, Skill Crane is my favorite, but it doesn't come on that much. I think they play the Splinter WAY too much. (Oh, and also they play the one with the Salty Spitoon too much.)

- Q:What kind of flower is the Sunset Crane?

- Okay, i'm going to get every backyard gardener east of denver jumping down my throat on this one, but it's time you all wake up and know the real name of one of your favorate potted plants. only then will you beleave me when i tell you the sunset crane is a type of geranium. the true geranium. not the plant most people know as the geranium is botanically Pelargonium. that silly looking, red flowered, fuzzy leafed thing everyone loves to stick in a pot by their front door every summer back east and mistakenly call a geranium is not really a geranium. even the fancy Martha Washington geranium is not a geranium. it is the Martha Washington Pelargonium. but whats the use? unless you are a botanist everybody back east is going to say i'm just another fruit cake from california. (born and raised in wisconsin i'd like to add) okay, your sunset crane is botanically a geranium, often called by it's common name cranesbill. okay, you have the real best answer, so go ahead and pick the wrong best answer from some smuck from back east who knows best. sure i have two post graduate degrees in science, been a univ certified master gardener for over 15 years and just might know a tad bit more then the eastern fair weather, summer time gardener. but don't let that prevent you from thinking i'm nuts and choosing a better, best answer. i'm used to it. grandma is always right... until her plant dies. then they call me for the real low down.

- Q:How do I get on the cranes on the Highrise map in MW2?

- watch that video its the easiest way to learn it and not have someone explain through text and what the hell is that first guy saying??

- Q:How do they get the cranes and counterweights down off the top of buildings when finished?

- sometimes they dont. i have heard of buildings where they left the crane body as the structure for the elevator

- Q:I'm confused about one of the final scenes, where Seneca Crane is locked in the room with the nightlock berries. Does this mean that he is supposed to eat the berries and presumably die? Or is it symbolism of some sort of distaste in the way he ended the Games?

- I think he is supposed to eat and die because Prez Snow got pretty angry at Seneca for having two winners for the Hunger Games

- Q:i have a report on it and its due on the 20th

- I'm from the Sandhills of Nebraska and that is where some of them come from.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Tower Crane TC7021 QTZ250 New Mast Section

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords