Tower Crane TC6520 Construction Equipment Building Machinery Distributor Sales

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Tower Crane TC6520 Description:

1.CMAX Tower Crane TC6520 is one of the main product of CNBM company, which have competitive price and excellent quality, suitable for all kinds of construction project and can work under all kinds of work condition.

2. Tower Crane TC6520 can adopts standard section hydraulic lifting and connecting, and can decide the crane height according to the actual height of the building, and at the same time the lifting capacity will not be affected.

3. Tower Crane TC6520 has high working speed, good speed-adjusting performance, steady operation and high efficiency. Three-speed motor and mono-speed ratio decelerator are applied in the lifting struction, which enables heavy load low speed and light load high speed.

4.Tower Crane TC6520 has complete set of safety devices, which can guarantee the safe and high efficienct operation of the equipment. The machine is equipped with lifting height limiter, dolly range-change limiter, moment limiter,weightlimiter,circumgyrating limiter,and so on.

5.Tower Crane TC6520 has scientific layout and beautiful appearance. The operator's room is set independently on one side, with good vision field. It creates a good working environment for the operato.

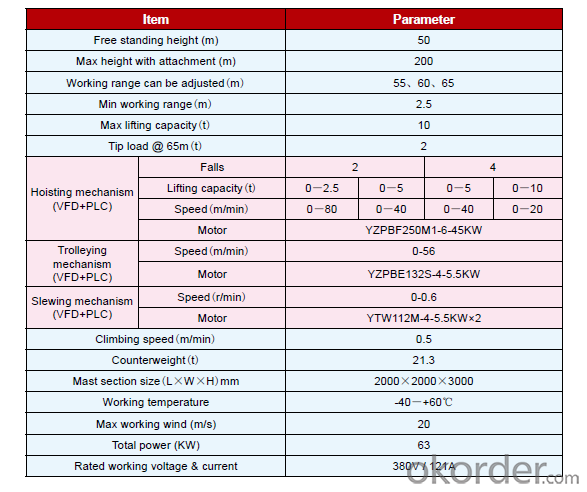

Tower Crane TC6520 Parameter:

Max. working range 65m, tip lifting weight 2T and Max. lifting weight 10T.

Hoisting mechanism fitted with three speed motor, stable braking and less shock when shifting.

Trolleying mechanism can provide two operation speeds.

Free standing height (m) 50

Max height with attachment (m) 200

Working range can be adjusted (m) 55、60、65

Min working range (m) 2.5

Max lifting capacity (t) 10

Tip load @ 50m (t) 2

Tower Crane TC6520 Packaging & Delivery:

40HQ container

20~25days after deposit

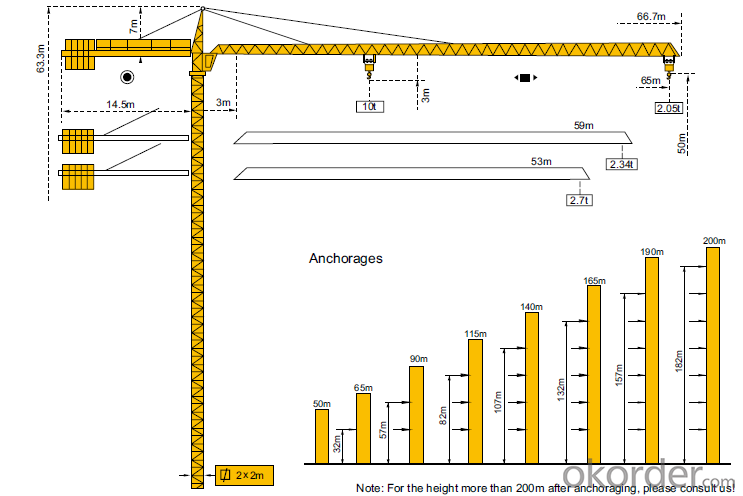

Tower Crane TC6520 Diagram:

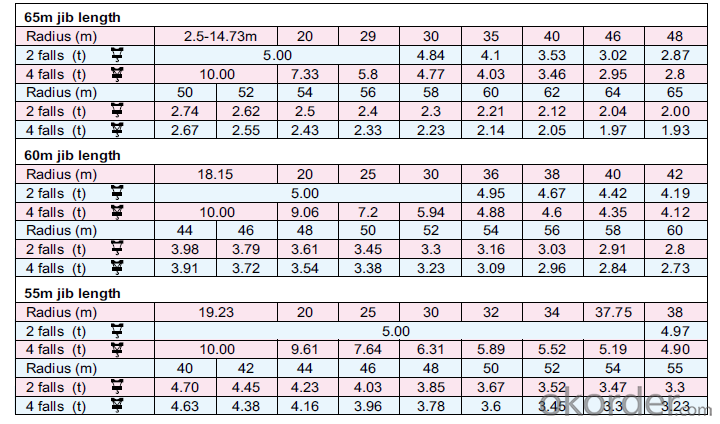

Tower Crane TC6520 Technical Sheet:

Tower Crane TC6520 FAQ:

1.What is tower crane?

Tower crane is a modern form of balance crane that consist of the same basic parts. Fixed to the ground on a concrete foundation (and sometimes attached to the sides of structures as well), tower cranes often give the best combination of height and lifting capacity and are used in the construction site.

2. What is the meaning of the tower crane’s code?

Take Tower Crane TC6520 for example, the first two letters “TC” means Tower Crane, “65”means jib length is 65meter, and the last two letter “20” means the tip load is :2 ton.

3. What is the principal to quote the right tower crane to the client?

First, we need to know clients’ requirements,for example, max lifting capacity, height, tip load and jib length.. Second, we need to know what the foundation requirement from the client is and Third if there are special needs. CNBM could suggest proposal according to clear data provided by the clients.

- Q:I loved Dr. Crane and his sexy glasses and eyes. Plus, I just love Cillian Murphy, haha. Is his character back in the Dark Knight, I heard he was...but I was wondering if anybody could confirm it?

- Just in the beginning in the movie for about 3 minutes when his parking garage drug deal is interrupted by a bunch of Batman wannabe's wearing hoaky Batman costumes and using guns. The real Batman arrives and Scarecrow takes off.

- Q:A site would be nice...

- I just used that poem for a project!

- Q:stories about paper cranes?

- Sadako and the Thousand Paper Cranes by Eleanor Coerr - about a girl who gets luekemia from the Atom bomb dropped on Hiroshima and her making paper cranes to pass the time in the hospital.

- Q:Denny Crane (played by William Shattner), and Alan Shore (played by James Spader) are partners in a Boston law firm. I would like to know if those those two are father and son in the series,

- No. They're just partners. Freddie Prinz Jr. Guest starred on i think 2 episodes as Denny Crane's son.

- Q:I am writing a short paper on the significance of the white doves and the crane in the book Sadako and I'm really not sure what to say.

- They had been ample and have been superb when cooked on an open hearth in the open air. When it used to be hot in those days, persons did not need to warmness up their kitchens and houses with the aid of making use of the oven. Electricity used to be high-priced then and with utilising the oven and having to show up the a/c it got rather highly-priced. Most families would decide on to pay money for different things reside significant display TVs and DVDs and Tivo. Additionally they appreciated having swimming swimming pools and fancy automobiles--so the opted to barbecue doves and save money for the opposite matters. As soon as Wal Mart went in everybody had to have cash to shop the revenue there every week. It's similar to today--no longer so much has modified, besides we do not devour too much dove--we consume hen, but it surely style like dove.

- Q:Tower crane TC6013A-6-A2, what does "A-6-A2" mean later?

- TC6013A-6-A2:TC is the abbreviation of tower crane, and 6013 is crane lifting moment, which means that 60 meters long arm tip can lift 1.3 tons. A says Model 6 means lifting capacity of 6 tons. "A2" means code.

- Q:can u have a small dog w/u when u are operating a crane?

- I can't imagine any employer allowing that condition to exist. A crane operator's attention must be on the job at all times. If the dog were to do something unexpected at a critical time, the operator may be distracted and lose control of the load.

- Q:heres a picture of one

- There are a few types. Some more modern cranes jack themselves up and then back down after wards. There is a large mis-conception about tower cranes. Many people think they can handle larger loads than portable jib cranes. This is not the case. The advantage of a tower crane is its cost and ability to see. The ones that are not capable of jacking themselves up are erected and taken down by large jib cranes with many times the lifting capacity and cost.

- Q:Brief introduction of ten no hanging criterion for tower crane operation

- 1, hanging weight more than no mechanical properties allow the crane; 2, the command signal is unknown, the weight is unknown, the dim light to hang; 3 working face, stand or floating active objects not hanging;

- Q:If a friend folded a thousand paper cranes for you what would you think?

- If a friend folded even a single crane for me it would be enough.I'd feel lucky for sure.Its the feelings of your friend that counts not Sadako's theory.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Tower Crane TC6520 Construction Equipment Building Machinery Distributor Sales

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords