Tower Crane TC5013B Construction Machiney

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 15 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction:

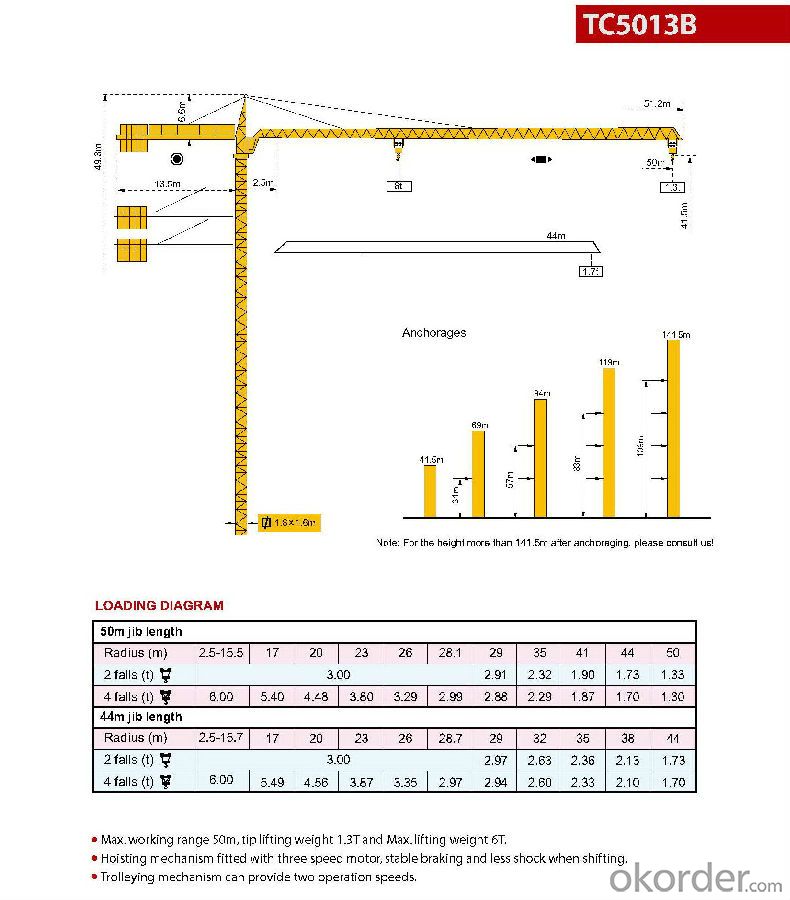

Tower crane is used to lift, lower and horizontally move materials in construction and other industry. It has large lifting capacity and lifting height, wide moving range, and can rotate. It basically consists of base foundation, mast, slewing unit, working jib, counter jib, counterweight, hook, and operating cabin.

Features:

1. Hoisting Mechanism

Three-gear speed modulation by electrical motor or frequency conversion, giant winch.

2. Rotation Mechanism

Speed modulation with frequency conversion, stable break, accurate position,

3. Luffing Mechanism

Speed modulation with frequency conversion, less concussion, stable operation.

4 Control System

PLC control, auto diagnosis on electric malfunction, alarm of light and sound, international top brand key components.

5. Security & Protection

In addition to usual standard security mechanism, this model adopts self-developed advanced mechanism, such as unique double tighten mechanism on luffing steel cable, anti-break mechanism on sliding vehicle, anti-drop mechanism on standard section, speedy link between rotary body, hoisting boom and balance boom.

6. Structure

Mechanical-electrical integration design, CAD supported design, optimization design, modularization design. Steel structure have outstanding intensity, firmness and anti-fatigue capability.

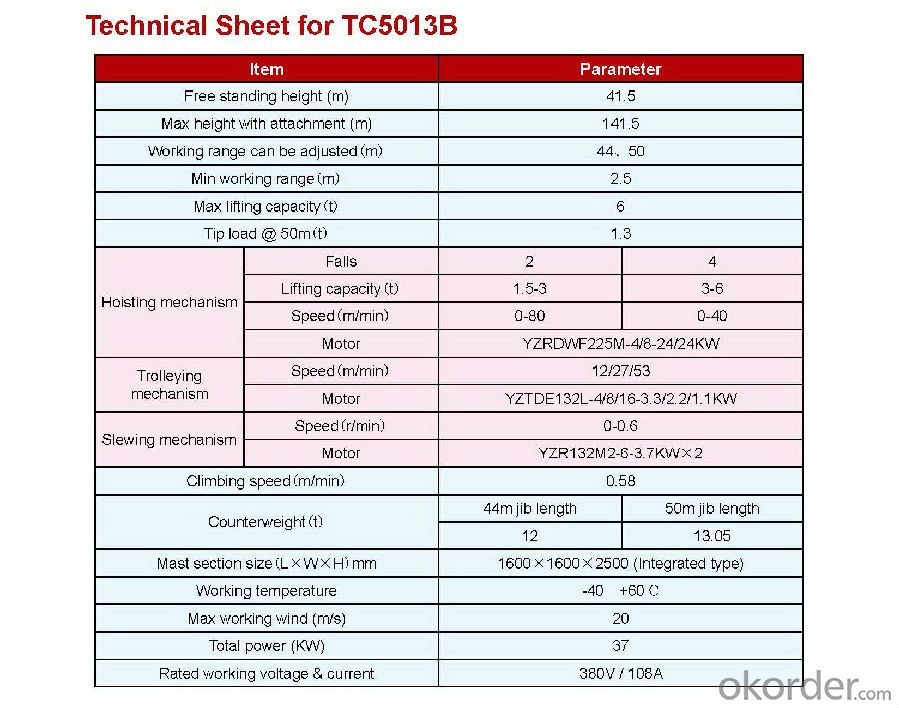

Specifications:

- Q:where does it live? what does it eat? How do you feel about it? (positive side)thank you! thank you! thank you!help!help!help!

- In the spring and summer, the Red-crowned Crane breeds in Siberia and occasionally in northeastern Mongolia (i.e., Mongol Daguur Strictly Protected Area). Normally the crane lays 2 eggs, with only one surviving. Later, in the fall, it migrates in flocks to Korea, Japan, China, Taiwan, and other countries in East Asia to spend the winter. All Red-crowned Cranes migrate, except for a flock that is resident in Hokkaidō.

- Q:I don't really believe that the wish will be granted.Anyways I've really been into Origami and I remember reading in my Heroes book (slash the show) that a certain number of cranes means a wish. But before I start making all these cranes, I want to know if it's 100 or 1,000.So if you haven't gotten it in your head yet the question is:Is it 100 or 1,000 cranes to get a wish

- 1000 Cranes Wish

- Q:i probably sound like an idiot asking this question :Pis it electricity? fossil fuel burning involved? pulleys? how does the pulley work? any human power involved? specifically, how is it stupid to lift a chair that can be lifted by a person, with a crane?

- Most cranes are diesel engine powered hydraulics and hydraulic motor. So that would be fossil fuel. Some cranes use pulleys to magnify the total lifting capacity. A pulley magnifies work by exchanging distance for lifting power. For example, to lift a 10 ton weight 20 feet in the air, if you put four pulleys in there so that 80 feet of cable would have to be pulled up , then it would only take 1/4 the amount of power to lift that 10 tons (2.5 ton lifting force would lift it) Look at any links or wikipedia for how compound pulleys work.

- Q:please tell me thats not what i think it is O_O

- It probably is what you think. I've heard that they use whale parts to make some brands of lipstick so I wouldn't be surprised if they used parts of other animals in cosmetics. =X

- Q:Who is it? And when in the book do they say who it is?Thank you so much! :D

- was the head games maker in the first book or the 74th annual, now it's plutarch

- Q:explain thoroughly please

- Sure. Let's say that a crane needs to hoist a load of 10 tons, and that because it needs to reach over some obstacles, needs to lift at a horizontal distance of 50 feet away. That creates a torque about the base of the crane of 500 ton·ft. By positioning a counterweight on the opposite side of the tower, the magnitude of the moment can be mitigated. For instance, let's say a counterweight of 10 tons is positioned at 25 ft on the other side of the tower. The moment produced by the counterweight is 250 ton·ft, so the net moment at the base is 250 ton·ft. Furthermore, when the 10 ton load is positioned and release, there is still a 250 ton·ft moment at the base of the tower; it has simply switched direction (say from rotating the crane to the right, to rotating it to the left). If you find this helpful, please award Best Answer!

- Q:What are the main technical parameters of a tower crane?

- Generally speaking, the main parameters of the tower crane are:Maximum amplitude unit MMaximum lifting height, unit MMaximum lifting torque unit KN.mMaximum lifting speed unit m/minMaximum lifting unit tRotational speed unit r/minVariable speed unit m/min or o/minWalking speed per unit m/minMotor power unit w......Please refer to the product manual.

- Q:I have to build a hydralic system that can pick up a paper clip . the supplies you are allowed to use are 10 straws, 5 pipe cleaners, 1 yard of masking tape. 10 note cards. 2 syringes and tubing. 5 rubber bands. 8 popsicle sticks. 2 feet of string. 1 magnet. Please help.

- build a basic crane out of your materials and thread the string to the magnet hold it on with tape secure opposite end of the string to the plunger on one syringe. and fix this syringe(syringe 1) to the frame of the crane. position the plungers of both syringes at mid point, and fill both with water, and fill your tubing with water. connect the needle ends of both syringes together with the tubing. pushing the plunger on syringe 2 will cause the plunger in syringe 1 to move out. pulling the plunger on syringe 2 will cause the plunger on syringe 1 to retract and can be used to lift the paperclip.

- Q:Ok, so I figured out that last step after watching an origami tutorial thing on youtube

- It okorder / The animations on this site are good, showing what you have to do, without hands in the way.

- Q:Tower crane 5610 why is it called QTZ63?

- Q is reusable, T is tower, Z is jack up, and combined is jack up tower crane. (this is the earliest known China, now the various manufacturers have their own name, some close to the French take, such as F0/23B, the tower jib 50 meters, a maximum weight of 10 tons, 2.3 tons of weight lifting arm tip)80 is the moment, the unit is t * m, (should say is the force multiplied by distance, 800kn.m) for 5613 cranes, the maximum lifting capacity of 8 tons, the boom length is 56 meters, arm tip lifting weight 1.3 tons, maximum weight in the range of 2.5 meters ---13 meters, calculation of 8 * 13=104, so the name is QTZ104, now the provisions should be a QTZ104, but before, people think is 8 tons of weight, so called QTZ80, is now available.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Tower Crane TC5013B Construction Machiney

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 15 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords