Tower Crane of Chang Li Model Number QTZ50(TC5010)

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 888 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

QTZ31.5 (4075) Description

Feature: Jib Crane

Condition: New

Application: all kinds of construction

Rated Loading Capacity: 5T

Rated Lifting Moment: 500KN

Max. Lifting Load: 5T

Max. Lifting Height: 120m

Span: 50m

Place of Origin: Henan, China (Mainland)

Brand Name: YU JIE

Model Number: QTZ50(TC5010)

Certification: ISO/CE

Warranty: one year

After-sales Service Provided: Engineers available to service machinery overseas

Model: QTZ50(TC5010)

Working Radius: 50m

Tip Load: 1T

Max Load: 5T

Lifting Power: 18/18.5kw

Lifting Speed when load 5T: 5m/min

Trolley Travel Speed: 38/25m/min

Slewing Speed: 0.6r/min

Jacking Up Speed: 0.4m/min

Power Supply: 380V,50HZ

QTZ50(TC5010) Features

1.Thirteen years of experience in supplying new self-erecting tower crane with Huiyou Brand.

2. Export to more than 20 countries with CE/ISO/GOST Certificates.

3. Stationary/Travelling, external/ internal climbing tower crane

4. Impeller blasting/rust protection paint

5. Potain masts designed with dismountable panels, making teansport easier and cheaper.

6. New designed mast, can be used to Internal and external climbing tower crane

QTZ50(TC5010) Specification

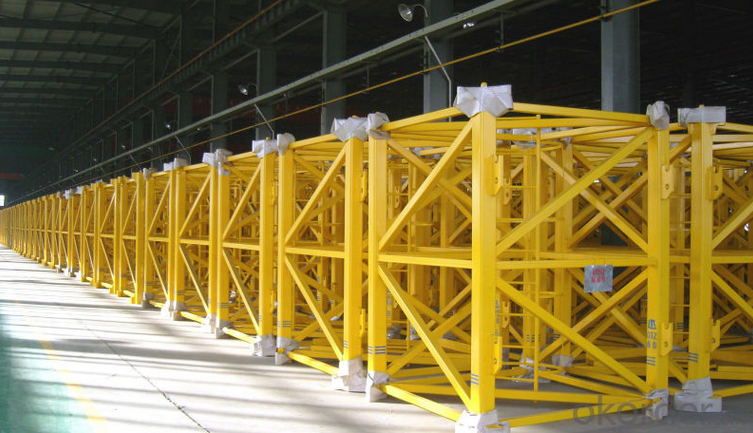

QTZ50(TC5010) Pictures

QTZ50(TC5010) FAQ

Q: What can we do for the clients in the market and after-sale service?

A: There is branch office for us in the kingdom and she could provide any commercial assistance for the clients; our exclusive agent would fully represent lifting machinery for business communication and rapid & professional technical support.

Q: What is tower crane?

A: Tower crane is a modern form of balance crane that consist of the same basic parts. Fixed to the ground on a concrete foundation (and sometimes attached to the sides of structures as well), tower cranes often give the best combination of height and lifting capacity and are used in the construction site.

Q: What is main advantage for manufacturing construction machinery?

A: Our machinery main advantages mainly include: 1. National-level Research Academy for various building equipment for more than 30 years’ experience; 2. Complete quality control system; 3. Nearly 20 years experiences in manufacturing industries; 4. Over 50 engineers along with 6 local partner companies providing worldwide after-sales service;

Q: What is the principal to quote the right tower crane to the client?

A: First, we need to know clients’ requirements. Normally the following information should be clarified by the client: max lifting capacity, height (height under hook), tip load and jib length.

- Q:What are the climbing claws on the tower crane?

- You mean the set section? Used to be rubber, and later found that when the top of the friction is too large, not too good, plus plus the festival, but also always remove the standard section paint, and now basically the pulley

- Q:i probably sound like an idiot asking this question :Pis it electricity? fossil fuel burning involved? pulleys? how does the pulley work? any human power involved? specifically, how is it stupid to lift a chair that can be lifted by a person, with a crane?

- Most cranes are diesel engine powered hydraulics and hydraulic motor. So that would be fossil fuel. Some cranes use pulleys to magnify the total lifting capacity. A pulley magnifies work by exchanging distance for lifting power. For example, to lift a 10 ton weight 20 feet in the air, if you put four pulleys in there so that 80 feet of cable would have to be pulled up , then it would only take 1/4 the amount of power to lift that 10 tons (2.5 ton lifting force would lift it) Look at any links or wikipedia for how compound pulleys work.

- Q:I am going to make 1000 paper cranes like Sadako Sasaki did. I am doing it to remember the victims of hiroshima and nagasaki and all the others who died as a result of wwii. especially sadako sasaki who, though she died in 1955, she was poisoned by the toxic gases in hiroshima. what do you think of my project, and got any tips to help?

- Yes, you are going to make 1,000 paper cranes. Here's a tip: After you are finished making them, do not forget to make 300,000 more paper cranes for the millions of Chinese who died as a result of Japanese aggression in the Sino-Japanese War.

- Q:So how does tower cranes and cranes used in constructions make use of mechanical advantage exerted from simple machines such as pulleys and levers?In other words, how does a crane use pulleys and levers?

- Well, think about it. The cables of the crane pass over pulley. That's one simple machine right there. In addition, one that not everybody would think is a lever. On the back of the crane, there is a huge weight. The purpose of this is to compensate for what is being picked up at the front of the crane. Having a very heavy weight on the back of the crane allows a load to be picked up far forward at the front of the crane. Otherwise, it would topple over and people would die. And that would be bad.

- Q:We had a very large tree removed from beside our house. The crane parked in the driveway and caused four very large depressions and crushed concrete.

- Your insurance won't pay for this. They may help you sue the company you hired. Their insurance should pay for the repairs.

- Q:They're so big

- large cranes are build at the factory and torn down and put together the first time, then after that the can be move in larger sections than when it came from the factory.

- Q:Tower crane (tower crane)

- Fixed tower crane, mobile tower crane, flat tower crane, movable arm tower crane

- Q:I used crane to fly me to the korean folk town area. im abck in the station that crane is at but i get up to reach crane. Is there a portal in town or a place i jump to? Please help!!

- what? take the next exit

- Q:How much does it cost to build 18, 22, 35, 40, 50, 70, 100, and 120 ton cranes?

- You would have to contact the crane manufacturer. Each size would have different cranes that meet that requirement, eg portable versus not portable. That's assuming those are total crane weight numbers? Or are they lifting capacities?

- Q:Information of distributor or manufacturer for Crane Lake Cellars will be helpful too.

- contact address crane lake cellars vineyard winery napa california

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Tower Crane of Chang Li Model Number QTZ50(TC5010)

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 888 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords