Tower Crane Max Lifting Capacity 10Ton New

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Detail of Tower Crane

Feature:Tower Crane

Condition:New

Model Number:TC6520(QTZ160)

Place of Origin: China (Mainland)

Brand Name: CMAX

Certification: ISO,CE

Warranty: 1 Year

Application:Building,Construction,Industrial

Main Features of Tower Crane

1) This kind of crane adopts standard section hydraulic lifting and connecting.The max. height can reach 180m with wall tie ins.

2) It has high working speed, good speed-adjusting performance, steady operation and high efficiency. Three-speed motor and mono-speed ratio decelerator are applied in the lifting struction, which enables heavy load low speed and light load high speed.

3)The range-change structure drives the trolley moving on the horizontal crang jib, with good positioning performance. Planet gear decelerator is applied in the circumgyrating structure, together with moment-limiting hydraulic coupler, which can relize high load capacity, steady starting and reliable operation.

4) The crane has complete set of safety devices, which can guarantee the safe and high efficienct operation. The crane is equipped with lifting height limiter, trolley ranging limiter, moment limiter, weight limiter etc..

5)The cranehas scientific layout and handsome appearance. The drivers cab is set independently on one side, with good vision field. It creates a good working environment for the operator.

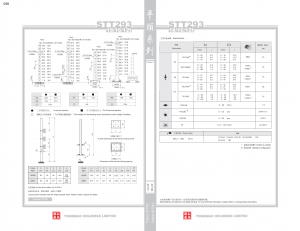

Specification of Tower Crane

Technical Sheet for TC6520

Free standing height (m) | 50 | ||||

Max height with attachment (m) | 200 | ||||

Working range can be adjusted(m) | 55、60、65 | ||||

Min working range(m) | 2.5 | ||||

Max lifting capacity(t) | 10 | ||||

Tip load @ 65m(t) | 2 | ||||

Hoist mechanism (VFD+PLC) | Falls | 2 | 4 | ||

Lifting capacity(t) | 0-2.5 | 0-5 | 0-5 | 0-10 | |

Speed(m/min) | 0-80 | 0-40 | 0-40 | 0-20 | |

Motor | YZPBF250M1-6-45KW | ||||

Trolleying mechanism (VFD+PLC) | Speed(m/min) | 0-56 | |||

Motor | YZPBE132S-4-5.5KW | ||||

Slewing mechanism (VFD+PLC) | Speed(r/min) | 0-0.6 | |||

Motor | YTW112M-4-5.5KW×2 | ||||

Climbing speed(m/min) | 0.5 | ||||

Counterweight(t) | 21.3 | ||||

Mast section size(L×W×H)m | 2×2×3 | ||||

Working temperature | -40-+60℃ | ||||

Total power (KW) | 63 | ||||

Power supply requirement (KVA) | 230KVA for generator | ||||

Cable type ( within 35 meters from site power source to lower electric box of tower crane ) | 50mm2(3+2, 5 cores) | ||||

Startup voltage & current | 380V×95%=361V 219A | ||||

Rated working voltage & current | 380V 121A | ||||

Loading diagram:

65m jib length:

R | 20 | 25 | 30 | 35 | 40 | 46 | 48 | ||

a=2 (t) | 5t---29.1m | 4.84 | 4.1 | 3.53 | 3.02 | 2.87 | |||

a=4 (t) | 10t---14.73m | 7.33 | 5.8 | 4.77 | 4.03 | 3.46 | 2.95 | 2.8 | |

R | 50 | 52 | 54 | 56 | 58 | 60 | 62 | 64 | 65 |

a=2 (t) | 2.74 | 2.62 | 2.5 | 2.4 | 2.3 | 2.21 | 2.12 | 2.04 | 2.00 |

a=4 (t) | 2.67 | 2.55 | 2.43 | 2.33 | 2.23 | 2.14 | 2.05 | 1.97 | 1.93 |

60m jib length:

R | 20 | 25 | 30 | 36 | 38 | 40 | 42 | ||

a=2 (t) | 5t---35.67m | 4.95 | 4.67 | 4.42 | 4.19 | ||||

a=4 (t) | 10t---18.15m | 9.06 | 7.2 | 5.94 | 4.88 | 4.6 | 4.35 | 4.12 | |

R | 44 | 46 | 48 | 50 | 52 | 54 | 56 | 58 | 60 |

a=2 (t) | 3.98 | 3.79 | 3.61 | 3.45 | 3.3 | 3.16 | 3.03 | 2.91 | 2.8 |

a=4 (t) | 3.91 | 3.72 | 3.54 | 3.38 | 3.23 | 3.09 | 2.96 | 2.84 | 2.73 |

55m jib length:

R | 20 | 25 | 30 | 32 | 34 | 36 | 38 | ||

a=2 (t) | 5t---37.75m | 4.97 | |||||||

a=4 (t) | 10t---19.23m | 9.61 | 7.64 | 6.31 | 5.89 | 5.52 | 5.19 | 4.90 | |

R | 40 | 42 | 44 | 46 | 48 | 50 | 52 | 54 | 55 |

a=2 (t) | 4.70 | 4.45 | 4.23 | 4.03 | 3.85 | 3.67 | 3.52 | 3.47 | 3.3 |

a=4 (t) | 4.63 | 4.38 | 4.16 | 3.96 | 3.78 | 3.6 | 3.45 | 3.3 | 3.23 |

Images of Tower Crane

FAQ about Tower Crane

Q: What kind of steel used for tower crane ?

A: Normally, as for the main force bearing steel structure, Q345B is adopted; as for the assistance force bearing steel structure Q235B is adopted. All of the raw material is outsourced from qualified steel factory in China.

Q: What about our tower crane warranty?

A: Usually there is one-year quality warranty including main electronic parts (not including consumable parts). There are consumable spare parts together with whole machine and normally they are enough for one year.

Q: What is 3 main mechanism of the tower crane ?

A: there are trolleying mechanism/ slewing mechanism/ hoisting mechanism.

- Q:How were Churches and really tall buildings constructed hundreds of years ago before the invention of cranes?

- Scaffolding, pulley systems, pure strength.

- Q:My great grandparents' kamon was the crane and I was thinking of getting it as a tattoo for a symbol of my family.However, I'm not sure which it is. I've bought a book on Japanese Crests especially for this, and saw a couple of crane crests but was wondering if there's an origami crane kamon? And if there is, what is the meaning of it?Thank you very much for the help in advance!

- I found an origami crane crest. It is called Orizuru Omodaka (折鶴沢潟) or Omodaka Orizuru (沢潟折り鶴). e-mon .jp/kamon/kamon12.html (on the 7th row, 2nd from the left) Orizuru = origami crane. As the previous answerer said, cranes are considered as sacred birds (reichou; 霊鳥) which bring us luck and happiness. They are also considered as a symbol of longevity as you can see in the following saying. 鶴は千年亀は万年 Cranes live for 1000 years, turtles live for 10000 years. Omodaka = a plant that stands near water. It is also called Kachigusa (勝ち草 = plant of victory). Hope this helps.

- Q:what does dog everything mean in crane lift lingo?

- it means to stop the crane from doing anything, just sit still untill otherwise told to carry on

- Q:...the crate weighs 4000N when resting on the ground. Find the followinga)The tension in the cable necessary to do thisb)The work done by the cablec)The work done by gravityd)The total work done by the systeme)The final velocity of the crate

- One-fifth of a g is 1.96 m/s?. The mass of the crate is... m = F / a = 4,000 N / 9.8 m/s? = 408 kg The force of the crane must be greater than that of the force of gravity. The acceleration must therefore greater as well. 9.8 m/s? + 1.96 m/s? = 11.8 m/s? a) T = ma = 408 kg x 11.8 m/s? = 4.81 x 10^3 N b) W = Fd = (4.81 x 10^3 N) x 25.0 m = 1.20 x 10^5 J c) W = Fd = 4,000 N x 25.0 m = 1.00 x 10^5 J d) W (total) = W (crane) + W (gravity) = (1.20 x 10^5 J) + (1.00 x 10^5 J) = 2.20 x 10^5 J e) v (final) = (v? + 2a?x)^(1/2) = ((0 m/s)? + (2 x 1.96 m/s? x 25.0 m))^(1/2) = 9.90 m/s I'm sure that all of my answers are correct. If anything is incorrect, please e-mail me again. Best of luck to you Jim.

- Q:Is a tower crane a fixed type crane? Still can walk? Thank you

- The tower crane is the equipment that can be used in the construction site and is not to walk.

- Q:Can someone find me a map that shows the geographic location of the white naped crane?

- it's not a map but it tells where theyre habitat range is.

- Q:Wall mounted tower crane

- The construction of tower crane installation, operation and dismantling safety technical regulations "(JGJ196-2010) design provisions in article 3.3 attachment device of tower crane: when the tower crane attachment for use, attachment device settings and free height should comply with the provisions of the instructions; when the attachment level distance, attachment spacing does not meet the the instructions to.

- Q:I want to make a sculpture out of 1,000 paper cranes. I have sometime to work on it, but not months. Has anyone ever known someone to do this, or done this themselves? How much time should I allow for such a project?

- I think it will be hard to tell, the easiest form to calculate is the time to make one crane times 1000. However, as long you fold you will get a little bit exhausted therefore you should add 1/5 of the total times to make of the 1000 cranes, good luck!

- Q:What is the load moment of a crane?

- The load moment for a crane is a number measuring the weight of the load lifted times the distance between the mass and the centre of the crane's superstructure. For example, a 20 ton weight lifted at 5m away from the crane (in reality, right next to it!) gives us a load moment of 100 ton*m, the same as a 10 ton weight lifted 10m from the crane. Cranes can handle higher load moments closer to the crane, so really heavy lifts are always done from very close to the load.

- Q:what are the effects of fiction in cranes?

- Uh.... Do you mean fRiction? And cranes... as in the machine or the bird..... Try to be specific.....

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Tower Crane Max Lifting Capacity 10Ton New

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords