Tower Crane Intergrated Mast Section Fast Delivery

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

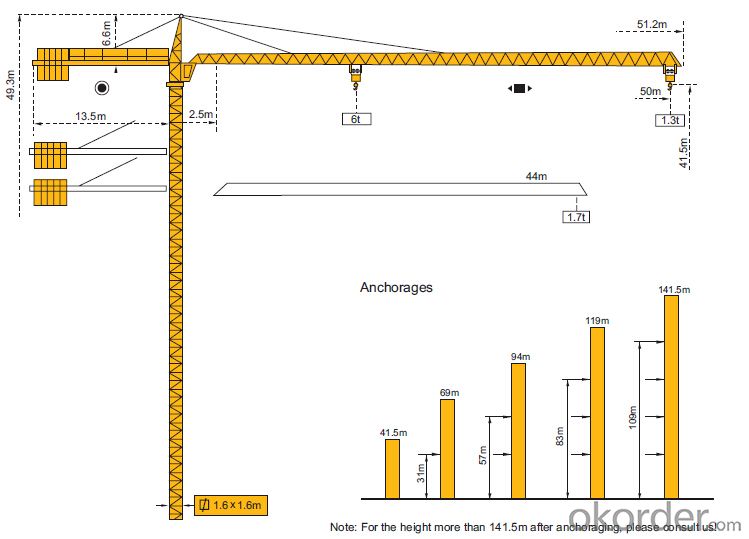

Detail of Tower Crane

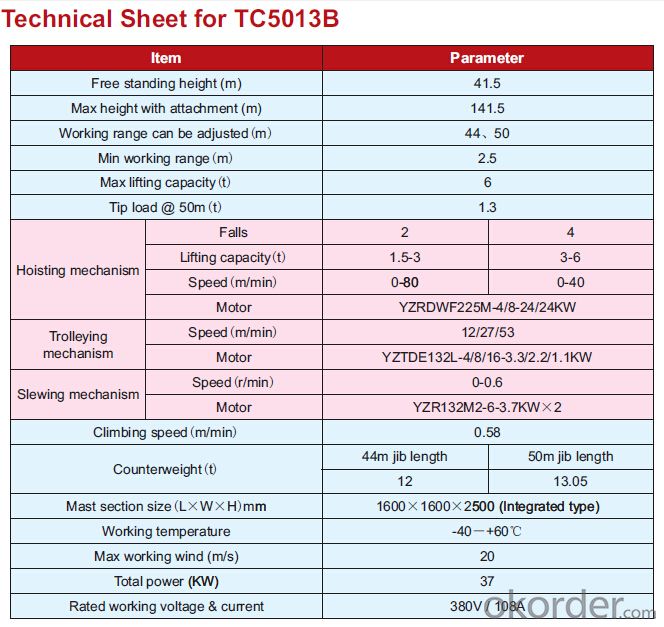

Feature:Tower Crane Condition:New Model Number:TC5013B(QTZ63) Place of Origin: China (Mainland) Brand Name: CMAX Certification: ISO,CE Warranty: 1 Year Application:Building,Construction,Industrial

Main Features of Tower Crane

1) This series of tower cranes, ranging from QTZ40 to QTZ400 has a horizontal jib frame, a jib-trolley radius-changing mechanism and a hydraulic self-raising mechanism. It is original in design, reliable in operation and satisfactory in shape. Equipped with all necessary safety devices, these cranes show a good speed-control capacity, satisfactory operating stability and high work efficiency. They can be widely used for the construction of high-rise hotels, residential buildings, high-rise industrial buildings, large-span factory buildings and tower-like buildings like tall chimneys.

2) It has high working speed, good speed-adjusting performance, steady operation and high efficiency. Three-speed motor and mono-speed ratio decelerator are applied in the lifting struction, which enables heavy load low speed and light load high speed. 3)The range-change structure drives the trolley moving on the horizontal crang jib, with good positioning performance. Planet gear decelerator is applied in the circumgyrating structure, together with moment-limiting hydraulic coupler, which can relize high load capacity, steady starting and reliable operation.

4) The crane has complete set of safety devices, which can guarantee the safe and high efficienct operation. The crane is equipped with lifting height limiter, trolley ranging limiter, moment limiter, weight limiter etc..

5)The cranehas scientific layout and handsome appearance. The drivers cab is set independently on one side, with good vision field. It creates a good working environment for the operator.

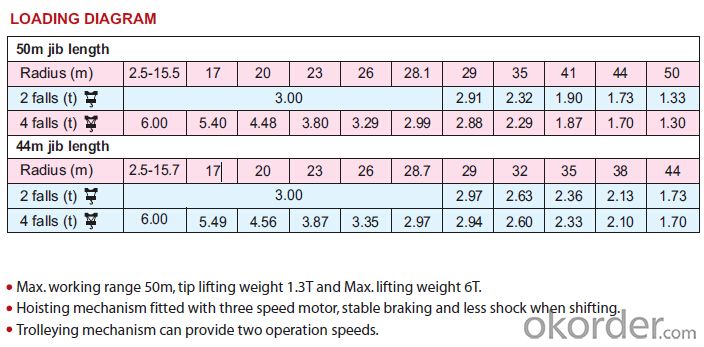

Specification of Tower Crane

Images of Tower Crane

FAQ about Tower Crane

Q: What serice you could provide? A: Providing timely delivery, standby engineers are ready to slove any of your problem Providing all-embraced warranty of products quality, worksite installation guidance Providing ample spare parts and training of operation and maintenance Engineers have more than 20 years' experience in tower crane, ready to solve any of your problems.

Q: What kind of steel used for tower crane ? A: Normally, as for the main force bearing steel structure, Q345B is adopted; as for the assistance force bearing steel structure Q235B is adopted. All of the raw material is outsourced from qualified steel factory in China.

Q: What about our tower crane warranty? A: Usually there is one-year quality warranty including main electronic parts (not including consumable parts). There are consumable spare parts together with whole machine and normally they are enough for one year.

Q: What is 3 main mechanism of the tower crane ? A: there are trolleying mechanism/ slewing mechanism/ hoisting mechanism.

Q: Can you equip with light on tower crane jib, monitor, remote control and anemometer? A: Sure. All of these could be provided with extra cost upon the clients' requirements. But according to general practice, remote control is not suggested because most of the operator feedback operation in the cabin will provide a wide working view. | |||||

| (0) | |||||

- Q:How many meters of cranes should be in accordance with the anemometer?

- Tower crane type test items, technical requirements and test methods provides that: Boom root hinge point height of greater than 50m tower crane, should be equipped with anemometer. When the wind speed is greater than the working limit wind speed, the alarm can be issued to stop the operation. The anemometer shall be installed at the top of the tower without the wind.In fact, this is also the requirements of the type test rules for tower cranes and the safety technical specifications for crane overload protection devices.The answer is recommended dogmatism, mainly because the standard setters do not understand the actual situation of the construction, and not the outdoor crane need, need only part of crawler crane and tower crane installation, as the case may be other.Welcome to the emperor student - lifting expert Sina blog, my blog is committed to the dissemination of hoisting safety and professional knowledge.

- Q:The rated lifting capacity of a tower crane refers to what is allowed and what is allowed to be divided by the crane

- The total quality of the crane rated liftingweightincludes the lifting load and the hook and rope a simplified example, such as the rated lifting weight of 100 tons, the quality of the hook and spreader for 5 tons, the actual quality of the goods can lift 95 tons.

- Q:Can the attached arm of the tower crane be welded?

- The following points: the calculation of tower crane according to the instructions provided with the attachment of the building, a maximum load attachment device (Fig. 14-44), therefore, should be in the way of adhering bar load as the design or check attached bar section basis.

- Q:job description of crane operator and truck driver?

- Crane operator has to be certified by the state and the truck driver has to have a class A drivers license :)

- Q:Please write in days, hours, weeks, etc.I need math help!!!!

- 13 years 8 months 2 hours 13 minutes 20 seconds

- Q:Is there a crane big enough to lift Hillary off the yoga matt when she has finished her yoga?

- Unfortunatly....

- Q:What are the working mechanisms and safety devices of tower cranes?

- A safety device: four limit: height limit, amplitude limit, slewing limit, travel limit; three insurance: luffing rope insurance, car insurance broken shaft, the hook to prevent falling insurance; two limit: torque limiter, weight limiter on these roughly.

- Q:A crane operator was extended his Tadano crane boom(two section of boom out of five) at almost 0 degree boom angle. My question is-Is it safe to lift any load at 0 degree boom angle.

- The answer is yes. The amount of the lift weight depends on the weight of the counter weights on the back of the crane. There is an indicator (printed or electronic) which indicates the maximum lift based on angle and extension. TexMav

- Q:which is crane lift planning software free to download?

- I okorder /

- Q:what is the meaning of the color red in the book The Red Badge of Courage by stephen crane?

- In some ways Crane's style is ornate, as has been noted above, with profuse use of color and rampant metaphor in a way which was rare for his time. The blues and grays of the two sides of the American Civil War are often described as natural phenomena, swirling like clouds. Fleming's Regiment was a broken machine. In dialog, however, the style is earthy, written out to sound as close to the vernacular of the day as possible. This realism was later to inform many works but was relatively rare at the time.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Tower Crane Intergrated Mast Section Fast Delivery

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords