Top Quality PPR female threaded socket Comply with Food Hygiene Regulations and Non-toxic

- Loading Port:

- Tianjin

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 2400 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Features

1. Corrosion resistance

PPR pipes and fittings can resistant to most chemical corrosion; it can withstand PH value range 1-14 high concentration of acid and alkali corrosion over a wide temperature range.

2. Installation performance

PPR pipe PPR pipe is light in weight, and the operation installation is easy, which make it available to weld again. It is very important that pipe and pipe fittings can be welded together in seconds with a simple tool. Compared to traditional connection methods it can save 40%~50% of the time.

3. Safety Indicators

The basic component of PPR is carbon and hydrogen which is simple. It keeps in line with food hygiene regulations, non-toxic. If you use PPR pipe, there will no dirt in the inner wall or “secondary water pollution” caused by rust any more.PPR pipe ,green building materials, is more suitable for transporting drinking water.

Advantages of PPR pipe

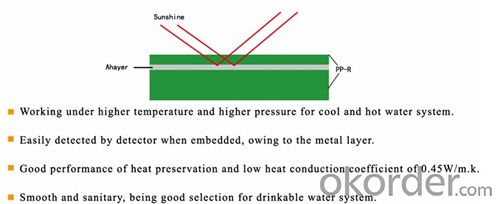

1. Maximum operating temperature can up to 95℃; it can work in a long term under the condition of 70℃ and 1.0Mpa.

2. PPR pipe density is only 1/8 of metal pipe; pressure resistance strength test is up 5Mpa, with good toughness, impact resistance.

3. Inner diameter of PPR pipe is little bigger than that of pipe fittings, which can ensure not to increase the resistance to fluid flow.

4. Inner wall of PPR pipe is smooth, no rust, no scaling, small fluid resistance

5. PPR pipe has excellent insulation properties, can significantly reduce the vibration and noise caused by the flow of liquid.

6. PPR pipe energy consumption is only 20% of steel pipe; its thermal coefficient is also only 1/200 of steel pipe, reducing heat loss greatly.

7. PPR pipe is poor electrical conductor material, which can avoid galvanic corrosion phenomena.

8. With poor thermal conductivity, PPR pipe can reduce condensation.

9. PPR pipes, fittings are recyclable.

Application

1. Hot and cold drinking water supply system of civil and industrial buildings

2. Clean, pure water piping system

3. Beverage production and transport systems

4. Industrial liquid delivery system

5. Central air conditioning system

6. Hot water circulation Heating System

7. Compressed air piping system

8. Garden and greenhouse irrigation systems

Advantages and disadvantages of PPR pipes

The full name of PP-R pipes with an international level of new energy-saving plastic products in the nineties is the random copolymer polypropylene piping. PPR installation and use of the advantages and disadvantages are as follows:

Advantages:

1. Harmless to human health, to all ions in water and chemicals in the building are no chemical reaction, compared with metal pipes do not rust, plastic water pipe will not corrode, and has a high degree of acid resistance and chloride resistance.

2. Belonging to the sustainable development green products. There is no environmental pollution in the process of production, construction and use. Secondary recovery can be repeatedly used.

3. Are different, homogeneous melt PP-R pipe is connected with other pipeline is the biggest advantage of this pipe system. Pipe connections disclose rate is very low, no maintenance, usable visual inspection, the joint firm could no corrode.

4. Light weight, easy handling construction, can greatly reduce the labor intensity, fast construction progress.

5. Good heat resistance: instant use temperature can reach 95 degrees. Long-term use at work pressure does not exceed 0.6Mpa, temperature up to 70 degrees. To meet the general needs of life and production of hot water, it is an ideal hot water pipe.

6. Low thermal conductivity: thermal conductivity of 20 degrees was 0.23 ~ 0.24W / Mk, much smaller than steel and copper. Used in air conditioning or hot water supply and drainage, you can save the investment in the pipeline insulation.

7. Elastic modulus is small: stress due to temperature change is small, suitable for direct burial, in-wall and floor surface layer Concealed way. With High-grade appearance, it is a trend of fashion.

8. Small pipe resistance: pipe wall smooth, non-furring, small head loss, head loss is smaller than the metal pipe; the local head loss is also smaller than the metal tube.

9. Performance can be repaired pipeline: full advantage of PP-R pipe hot melt, the use of PP-R of the eye of a needle stick fill holes in the pipeline repair can also be cut out the damaged pipe replacement pipe.

Disadvantages:

1. Higher cost: With the continuous promotion of the pipe is now ready to accept the price, but the price is still too high, pipe fittings, because one mold imports; Second, copper and stainless steel fittings materials pipe fittings are used in special requests these metals temperature coefficient and accessories for a temperature coefficient of PP-R materials strict consensus, now also need foreign imports.

2. PPR size is only a small outer diameter of 20-110 mm diameter products; types of fittings and valves missing, there is connected to the metal valves inconvenient questions.

3. Rigidity and impact resistance worse than metal pipes.

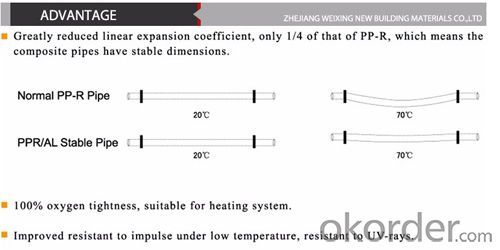

4. Larger coefficient of linear expansion, for surface or overhead required to lay more pipe hangers, affect the appearance.

5. Construction equipment advanced complex, construction technology requirements, construction workers and construction quality management requirements high. Joint quality and temperature of the hot melt connection, heating time, the seam stress-related, construction prone to bias.

6. UV resistance is poor, in the long sunlight easy to aging.

7. PP-R pipe belonging to combustible materials, it cannot be used for fire water supply system.

- Q:I don't need the candy, just the tubes. Do you know where I can buy them in bulk , and at a reasonable price?

- OKorder might have them. If not, find a candy supply company.

- Q:A plastic tube allows a flow of 12.4 cm3/s ofwater through it.How long will it take to fill a 215 cm3 bottlewith water? Answer in units of s.

- Take 215 cm^3 and divide it by 12.4 cm^3/s, and you'll have your answer. T = (215/12.4) s

- Q:Can plastic tubes be used for gas lines?

- Yes, plastic tubes can be used for gas lines.

- Q:Can plastic tubes be used for storing sensitive electronic components?

- No, plastic tubes are not suitable for storing sensitive electronic components as they do not provide adequate protection against electrostatic discharge (ESD) and can generate static electricity, potentially damaging the components.

- Q:How can I get the feed to keep going down into the cups? The birds peck it out, but it never goes back into the feeder cup. I have to go out and use a wire hook i made up to get it back in the cups so the birds can reach it again. It is a 4 port, about 18 inches tall, the cups are closer to the bottom, so yo'd think the weight would push the seed down into the cups. Very frustrating. It is a plastic tube maybe 1.5 inches wide, and I use black oil sunflower seed (not the shelled kind)

- Yeah, get seed mix, not 100% sunflowers. And my cousin did this. It has a hole for the seeds to come out, not a little slit, right? The feeders with the slits are for thistle seed, not normal seeds.

- Q:Are plastic tubes suitable for hydroponic systems?

- Yes, plastic tubes are suitable for hydroponic systems. They are commonly used as a cost-effective and versatile option for transporting water and nutrients to the plants in a hydroponic setup. Plastic tubes are lightweight, easy to install, and resistant to corrosion, making them a practical choice for hydroponic gardening.

- Q:I have forgotten the name of the breed altough i know it starts with sy. I just want to know if they can fit in a tube cage or will they get stuck? And what is the best breed to get if you do have a tube cage?

- Syrian hamsters, the larger breed of hamster, can outgrow the tubes and get stuck. Dwarf hamsters are better suited for those types of cages. If you're interested in a syrian hamster, a large, basic wire cage is probably a good idea. A bin cage is also a good cage to have for hamsters.

- Q:How are plastic tubes used in the packaging industry?

- Plastic tubes are commonly used in the packaging industry to store and protect various types of products, such as cosmetics, pharmaceuticals, and food items. These tubes offer a convenient and hygienic packaging solution, allowing for easy dispensing and application of the product. They are often sealed with a screw-on or flip-top cap to prevent leakage and ensure product integrity. Additionally, plastic tubes can be customized with labels, logos, and other branding elements, making them an effective marketing tool for businesses.

- Q:just needed to know before i ran into a potential disaster! lol -any tidbits of advise would be gladly accepted =)gt;

- Hi, without any details it's difficult speculate but if you have never done anything like this before successfully or the tanks contain living creatures I would say forget it-the potential for disaster is VERY great! As a caveat have a look at the link below for what is possible with a great deal of money, time engineering know-how.

- Q:Can plastic tubes be used for DIY projects?

- Yes, plastic tubes can definitely be used for DIY projects. They are versatile and can be cut, shaped, and connected to create various objects such as storage organizers, planters, furniture, or even simple plumbing systems. The choice of plastic tube material will depend on the specific project requirements, but options like PVC, acrylic, or ABS tubes are commonly used due to their durability and easy availability.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Top Quality PPR female threaded socket Comply with Food Hygiene Regulations and Non-toxic

- Loading Port:

- Tianjin

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 2400 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords