Top Heat Insulation Ceramic Fiber Blanket HA

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 5000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

セラミックファイバーモジュールの一般的な情報

cmaxセラミックファイバーモジュールの高品質のカオリン粘土で作られ、遠心力高純度アルミナとシリカまたはプロセス。それはアスベストです。ダブルサイドの鍼治療は、モジュールを提供して、大きな引張力または強さで、インストールするのが簡単にします。

製品の高圧力標準とに分けられ、それぞれhaと、1000、1100、1200の最高使用温度に対応して、1350

セラミックファイバーモジュールの特性

熱抵抗

ライトウェイト

低熱伝導率

低熱貯蔵

熱衝撃靭性

高引張強度

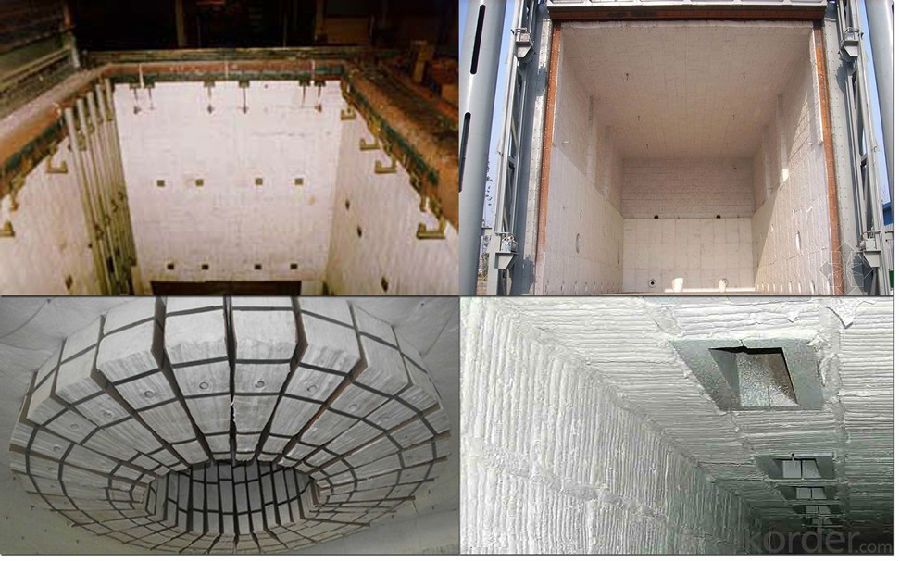

セラミックファイバーモジュールの応用

石油化学プロセス加熱炉用耐火繊維ライニング

熱処理炉または間欠的(シャトル)窯の熱面の裏

一般的なオーブンの予備絶縁

ドアのシールや窯の窯車熱

電気絶縁

セラミックファイバーモジュール

一般的な問題の解決

1。どのような製品を持っていますか?

我々は、すべての種類の耐火レンガ、耐火キャスティング材料、モルタル、セメント、セラミック繊維製品など。

または、あなたはあなたが必要とするものを選ぶ我々の製品を閲覧することができます。

2。製品の品質をコントロールする方法?

と厳しい品質管理システムは、材料の選択と製造プロセスを通して、我々は、顧客の要件を満たす耐火材料とセラミック繊維製品の品質があります。

原料の選択から始めて、我々は、制御の品質。原料の品質証明書が必要ですが、製品の各バッチ転送ラインの使用でテストされる。製造工程において、労働者によって品質管理、そして各作品の分類と品質管理と検査を通して。

3。あなたは私にあなたの製品のアプリケーションへの短い導入を与えることができますか?

私の会社は鉄鋼、セメント、ガラス、セラミックス、石油化学における耐火物で主に従事している電力と他の産業。

4。私はあなたに必要な情報を必要とするならば、何をしますか?

正しい製品を選択するために、我々は我々に情報を提供するように、米国の技術データ、受注量、製品の応用など。

あなたが質問をするならば、我々に連絡してください。

特殊な問題の解決

1。どのような製品を持っていますか?

我々は、すべての種類の耐火レンガ、耐火キャスティング材料、モルタル、セメント、セラミック繊維製品など。

または、あなたはあなたが必要とするものを選ぶ我々の製品を閲覧することができます。

2。製品の品質をコントロールする方法?

と厳しい品質管理システムは、材料の選択と製造プロセスを通して、我々は、顧客の要件を満たす耐火材料とセラミック繊維製品の品質があります。

原料の選択から始めて、我々は、制御の品質。原料の品質証明書が必要ですが、製品の各バッチ転送ラインの使用でテストされる。製造工程において、労働者によって品質管理、そして各作品の分類と品質管理と検査を通して。

3。あなたは私にあなたの製品のアプリケーションへの短い導入を与えることができますか?

私の会社は鉄鋼、セメント、ガラス、セラミックス、石油化学における耐火物で主に従事している電力と他の産業。

4。私はあなたに必要な情報を必要とするならば、何をしますか?

正しい製品を選択するために、我々は我々に情報を提供するように、米国の技術データ、受注量、製品の応用など。

あなたが質問をするならば、我々に連絡してください。

- Q:-Explain Ohm's Law and give several mathematical examples.26Calculate the current where 10 coulombs of charge pass a point in 5 seconds.27Calculate the current of a lightning bolt that delivers a charge of 35 coulombs to the ground in a time of 1/1000 second.28Calculate the current in a toaster that has a heating element of 14 ohms when connected to a 120-V outlet.29.Calculate the current in the coiled heating element of a 240-V stoveThe resistance of the element is 60 ohms at its operating temperature.30Electric socks, popular in cold weather, have a 90-ohm heating element that is powered by a 9-volt batteryHow much current warms your feet?31How much current moves through the fingers (resistance: 1200 ohms) if you touch them to the terminals of a 6-volt battery?32Calculate the resistance of a filament in a light-bulb that carries 0.4A when 3.0 V is impressed across it.33Calculate the current in a 140-W electric blanket connected to a 120-V outlet.

- I think either concrete or vermiculite would be the best , in that order.

- Q:Do you guys have any recommendations for bulky yarn that isn't made of wool? I find that wool tends to shed.

- heat it up and scrape it off with a scpaper just dont burn your self

- Q:My hair is a little past my shoulders, curly/wavy, blonde, and frizzyIs there any way to make it really shiny and preferably homemade? What should I do with my hair to make it irresistable to every guy in my school, without having to cut it? I'm tired of it now, and I need everyone's help! I appreciate it! Merry Christmas

- Your not gonna find it in Pittsburgh.Why don't you ask your friend if they know the recipe for it and surprise them by making it, OR the two of you try making it as a joint venture in the kitchenOR you could call his parents for the recipe.You might want to get a New York phone book and look there for a place that makes the desert you so desire.

- Q:OK, WE ALL KNOW THAT A HIGH-FIBER DIET IS GOODIT MAKES STOOL BIGGERIT SPEEDS UP TRANSIT TIME OF UNDIGESTED FOODAND BLOCKS SOME CARBS AND FATSMY QUESTION IS.SINCE WHEN YOU ARE ON A HIGH-FIBER DIET, YOU WILL BE CRAPPING LIKE EVERYDAY OR TWICE A DAY OR MORE, MEANING TRANSIT TIME OF FOOD IN THE DIGESTIVE SYSTEM IS FAST.SO, IF THE TRANSIT TIME OF FOOD IS FAST, DOES THE BODY GET ENOUGH NUTRIENTS FROM THE FOOD YOU ATE? AND SINCE YOU WILL CRAP ALOT DOES IT MEAN YOU WILL ALSO LOSE SOME ELECTROLYTES ETCFROM CRAPPING ALOT.THANK YOU

- i've got by no ability accomplished thatlolz they're outdatedomg ewfor a sec i presumed it became favourite element for you adult adult malespickup lines to get them terrific suited? i became thinking pickup jokesundesirable dora.

- Q:What are some pescetarian paleo foods that are really high in fiber? Also by starting the paleo I'm not missing any nutrients am I? How can I make sure I'm not?

- well my mom bakes it in water 4 50 min then lets it marinate over night then with seasoning it and lets it bake the next morning so here is it in steps 1st get some chicken then bake it use foil and water for 50 min and you know the other stuff and psfrying is bad for you but it is goodLOLOLOLOLOLLLOOLOLOLOLOLLOLOLOLOLOLO.

- Q:how to calculate gsm of fabric with knitting parameters like gauge, machine type, coursees , wales, yarn count.

- Multiply the kitchens by the bludgeons to get the fabric gsmOf course this does not work if you're using acrylicsThese fibers need to be ironed before processing.

- Q:I've seen a few pics of homemade yarn dreads (though I always love seeing more!!), and I noticed that most people suggest using woolCan any type of yarn be used to make something at least similar to dreads, or is wool the ultimate way of going about it??

- Does that mean they are located in the principal energy levels? Yes elements can only have a maximum of 8 valence electrons, so that can't be the caseNevertheless, it isThe n 1 level can only hold 2 electrons (s subshell), so there are only two elements on the first row of the periodic table: Hydrogen and HeliumHe has a full outer shell with 2 electronsThe n 2 level can hold up to 8 electrons (s and p subshells)There are 8 elements on row 2 of the periodic table, and the inert element Neon has 8 electrons in its full n 2 levelYour confusion probably starts at the n 3 levelIt has an s, p and d subshell holding 2, 6 and 10 for a total of 18 electrons altogetherYes that shell is indeed full with 8 electrons, when the s and p subshells are fullThat element is ArgonYet there's still a 3d shellWhen you get to the middle of the periodic table, you start filling that upRow 4 of the periodic table starts by filling up the 4s shellBut then starting with Sc (element 21), you start filling up 3d while you have only 2 electrons in the 4sAt Zn (element 30) the 3d shell is full, the n 3 shell is full, and then you start filling up the 6 electrons in the 4p shellThere's still a 4d shell, but you don't start filling that till the middle of the n 5 rowAnd there's a 4f shell which is being filled from elements 57-70 which is after the beginning of the n 6 rowAt this point my memory of chemistry class breaks downI know this order has to with energy, that 3d is higher energy than 4s, and that 4d is higher energy than 5s, and that's why it fills afterI don't recall why an element with 4s and 4p is inert though, even though there's a 4d levelIt also has to do with energy I suppose.

- Q:There is alot of freespace behind the drawers and cupboardsCould I use the roll of insulation and line this free space? I am a fulltimer and anything I can do to keep it warmer and cooler would be a plus.

- on the side of his pc ver there will be a console on the wall use it to open the secret door follow hall way down and you will come across another computer just keep doing that you will end up taking a elvator to his chamber but be warned the moment you open the secret door frist one all robots turn hostile

- Q:Insoluble Fiber Powder mix has me feeling dizzyIs that normal?

- The link didn't work, but buying anything from a sketchy source, like, not regulated or from a country that doesn't regulate things like that, or not from the drug store or somethingnot the best ideaIf you don't feel rightDon't use anymore of it at allThrow it in the trashI don't care how much you spentIt's not worth it to eat anymore I don't know how much you paid, but just go to the store and get something regular like metamucilMuch cheaper, I'm sureFiber supplements are usually cheap and fiber makes you feel full soonerIt doesn't have to have a fancy labelIf you look at diet pills, a lot of them are just fiber with a fancy labelNo different from fiber supplementsAnother thing that helps you feel full is proteinEating nuts or a protein bar or shake can helpGo for those insteadThey're all safer alternatives than buying from some greasy OKorder dealerYou don't know what's really in it unless it's from a trustworthy sourceFiber supplements also have a lot of soluble fiber usuallySoluble fiber is good because it can lower bad cholesterol! YaaaayAnd expect to have tummy troubles if you're increasing your fiber intake by a lotYour digestive system has to adjust and get used to itYou'll be gassyGood luck!

- Q:What is the best way to block knitted items made with man-made fibers?

- Cans of acidic liquids will corrode through in a couple of years or even lessI've seen it personally when my juice I never touched just blew out and made one heck of a messI'm sure tomato juice will do close to the same thing as it is acidic as well.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Top Heat Insulation Ceramic Fiber Blanket HA

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 5000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords