Top-grade Ceramic Fiber Blanket

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

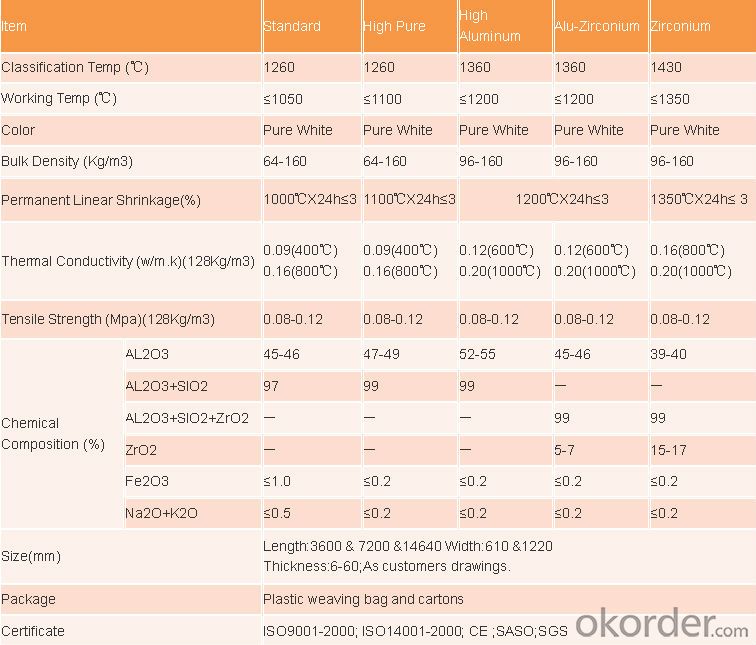

1. Type:STD, HP, HA, HZ

2. Density:64-160kg/m3

3. Service temp:1050-1350C

4. ISO9001:2000, Rohs report

5. Thermal insulation

Aluminum silicate ceramic fiber blanket is manufactured from aluminum silicate fiber bulk spinning from kaolinite, alumina silicon dioxide and zircon sand, which been series processing of needling ,cutting and rollings, including 1260°C Standard, 1260°C High pure, 1360°C High Aluminum,Alu-Zirconium 1430 C Zirconium ceramic fiber blanket.

Product information

Item | Ceramic Fiber Blanket |

Type of Blanket | Standard,High Pure, High Aluminum ,Al-Zirconium,Zirconium. |

Classification Temperature | 1260°C,1360°C,1430°C |

Applications | •The industry kiln, heating device, high temperature pipe lining •Power boiler, gas turbine and heat and nuclear power insulation •Chemical industrial high temperature equipment and heating equipment lining •Fireproof and heat insulation for high building •High-grade household appliances thermal insulation device •High temperature filtration etc |

Features | •Low thermal conductivity, low thermal capacity •Excellent thermal stability and good resistance to heat shock •Excellent tensile strength •Good anti-stripping performance •Good Sound-absorbing performance •Non-brittleness material, good flexibility •Excellent machining performance •Resistance to wind and erosion, long service life •Excellent heat insulation, fire prevention, sound absorption performance |

Payment Terms | L/C, D/A, D/P, T/T, Western Union, MoneyGram, Cash. |

Delivery Time | Within 15 days after received the deposit. |

Technical data

- Q:How to measure the influence of high-temperature performance of the products refractory in the formation of the liquid phase.

- Seeing whether it can affect the usage of the refractory material, and seeing to reduce the impurity, what's the condition of temperature of the liquid phase. Practically, whether it has any difference if you can improve, load under load and creep and reduce the impurity content. In the refractories, producing liquid are the influence of impurities, high temperature resistant strength, compared the use of the refractory material temperature: testing compressive strength after burn. If there are any impact: knowing the main crystal phase of matrix composition and content, improving the content of the main crystalline phase can improve the high temperature performance of refractory materials.

- Q:The development prospect of fire-resistant material

- Exported bulk material amounts to exported raw material/ To protect domestic resources, many countries have set linitations on the magnesium content in shapeless refractory material and lisences.

- Q:The fire prevention board line is made of what material?

- (1) if it's real wood floor, the line should be made of wood. The ready-made wooden line, walnuts, price range depends on the texture width. The common width is 100 mm. One linear meter is around $17 - $30. Paulownia is cheaper with one linear meter more than 10 yuan. When it is composite wood floor, high-density plate modelling line can be used. The price is commonly between 40 to 80 yuan (2400 x 1200 mm), which depends on the thickness and density and also the factory. There are also imitated wooden aluminium line. (3) if it's the marble ground, you would better use marble line, which is 200 yuan one square meter. It's price is also unequal. The imitated stone is also available. There are a lot of kicking decoration materials and it depends on how you use it. That is to say crural line should be coordinate with the ground. It means that it sjould not only to be beautiful but also to be practical. It would be better if it is relatively cheap as well.

- Q:Are refractory materials and fireproofing materials the same?

- Both refractory materials and fireproofing materials belong to the industry of construction materials and each of them can also be treated as an specific industry.

- Q:What are the main components of refractory cement?

- Refractory cement, also known as aluminate cement, can also be gray. Aluminate cement is often yellow or brown. Aluminate cement takes bauxite and limestone as raw materials, alumina content of about 50% as the clinker. And it is a hydraulic cementing material made by grinding. The main mineral of aluminate cement is mono calcium aluminate (CaO · Al2O3, abbreviated CA) and other aluminates, and a small amount of dicalcium silicate (2CaO · SiO2), etc.

- Q:What's the commonly used refractory material for ladle?

- Commonly used types of refractory material for ladle are as follows: high-alumina brick, clay brick, magnesia-carbon brick, aluminum carbon brick, magnesia chrome brick, spinel brick, corundum brick, high alumina castables, aluminum silicon carbide carbon castables, refractory castables for ladles, magnesium castables, magnesia chrome spray coating, dry vibration materials, etc. Hope it's helpful for you!

- Q:Which one is better, fire-resistant wood or steel?

- According to my understanding. This fire-resisting wood is better. Iron birch. The iron birch is three times harder than the oak, twice as hard than ordinary steel. It is the world's hardest wood which is used as a substitute for metal. The Soviet Union have used iron birch for the manufacturing of roller ball, bearings and it is applied in yachts. Iron birch has some wonderful characteristics. Since it has very dense texture, once put in the water it will sink; even if it is soaked in the water for a long time, the inside still remains dry. The iron birch is twice harder than the steel, it doesn't mean that its hrc value is twice of that of the steel. HRC means test load 1471.1N (150KG-F) using a diamond cone head with the point angle of 120 degrees to press. The calculation formula HR= (K-H) /C,K=0.2MM,H is the depth of indentation after releasing the major load. C= 0.002MM, so HRC100 is a limit value, then H is 0, which means that even the diamond will not drill into it. Generally the hardness of bearing steel is about HRC60. Iron birch is the championship among trees in terms of hardness. The bullet hit the wood is like hitting on a thick steel plate and the wood will be motionless. So, it is known as a tree harder than steel. I hope my answer will be helpful to you.

- Q:The manufacturing technique of refractory material

- The major components of alkaline refractory material include magnesium oxide and calcium oxide. The commonly used alkaline refractory material is magnesia bricks. The magnesia bricks with 80%~85% magnesium oxide has good resistance to basic slag and slag and higher refractoriness than clay bricks and silica bricks. It is mainly used in open hearth, oxygen blowing of converter, electric furnace and smelting non-ferrous metal equipment and other high temperature equipment. Refractory materials applied on special occasions include high temperature oxide refractory materials such as alumina, lanthanum oxide, beryllium oxide, calcium oxide, zirconium oxide, etc., refractory compounds such as carbide, nitride, boride, silicide and sulfide, etc., and high temperature composite materials, including metal ceramics, high temperature inorganic coating and fiber reinforced ceramics, etc. Consult and find reference for efractory materials production equipment, go to http://hi.baidu.

- Q:What kind of refractory materials should be used for the intermediate frequency furnace to smelt manganese?

- I am not quite clear. But you should take two aspects into consideration, namely, no pollution and strong durability.

- Q:How to divided the grade of external wall thermal insulation materials?

- Synthesized the three versions of GB8624 (1997,2006,2011), external wall thermal insulation fire?rating can be basically divided into: A1, A2, B1, B2, B3 and other levels. There are many technical indicators to make specific division, but I partly cannot report for a while, because it is very professional and technical. I hope I can help you!

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Top-grade Ceramic Fiber Blanket

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords