TMT Reinforced Bars 10mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

TMT Reinforced Bars 10mm

Description of TMT Reinforced Bars 10mm

1, Diameter: 5.5mm-10mm TMT Reinforced Bars 10mm

10m- 40mm TMT Reinforced Bars 10mm

2, Length: 6m, 9m, 12m or customized

3, Standard: GB, ASTM, AISI, SAE, DIN, JIS, EN

OEM technology - send detailed technical parameters for accurate quotation.

2, Produce Process: smelt iron - EAF smelt billet - ESR smelt billet -

hot rolled or forged to get the steel round bar and plate

3, Heat Treatment: annealing, normalizing, tempering, quenching

4, Surface Treatment: Black

5, Quality Assurance: We accept third party inspection for all orders.

You can ask testing organizations such as SGS, BV, etc. to test our products before shipping.

Chemical Composition of TMT Reinforced Bars 10mm

Grade | Technical data of the original chemical composition(%) | |||||

Reinforcing steel bar HRB335 | C | Mn | Si | S | P | B |

≤0.25 | ≤1.60 | ≤0.80 | ≤0.045 | ≤0.045 | >0.0008 | |

Physics Capability | ||||||

Yield Strength(N/cm2) | Tensile Strength(N/cm2) | Elongation(%) | ||||

≥ 335 | ≥490 | ≥16 | ||||

Reinforcing steel bar HRB400 | C | Mn | Si | S | P | B |

≤0.25 | ≤0.16 | ≤0.80 | ≤0.045 | ≤0.045 | 0.04-0.12 | |

Physics Capability | ||||||

Yield Strength(N/cm2) | Tensile Strength(N/cm2) | Elongation(%) | ||||

≥ 400 | ≥ 570 | ≥ 14 | ||||

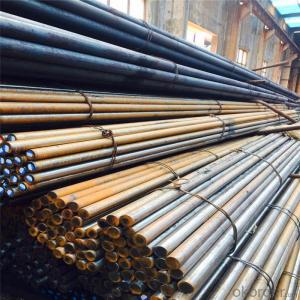

Products Show of TMT Reinforced Bars 10mm

Company Information

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

F A Q

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

- Q:How does special steel perform in high-wear applications?

- Special steel performs extremely well in high-wear applications. Its unique composition and properties, such as high hardness, toughness, and resistance to abrasion, make it highly durable and capable of withstanding intense wear and tear. This makes special steel an ideal choice for a wide range of demanding applications, including manufacturing tools, machinery parts, and components in industries such as mining, construction, and automotive. Overall, special steel's exceptional performance in high-wear applications ensures longevity, reliability, and cost-effectiveness.

- Q:How does special steel perform in terms of thermal conductivity?

- Special steel typically has lower thermal conductivity compared to other materials. This means that it is not as efficient in conducting heat and may retain heat for longer periods of time.

- Q:What are the different surface treatments used for special steel?

- There are several surface treatments commonly used for special steel, including galvanization, nitriding, carburizing, and plating. Galvanization involves applying a protective zinc coating to prevent corrosion. Nitriding is a heat treatment process that enriches the surface of the steel with nitrogen, enhancing hardness and wear resistance. Carburizing involves introducing carbon into the steel's surface, creating a hardened layer. Plating, on the other hand, involves covering the steel with a thin layer of another metal, such as chrome or nickel, for improved aesthetics and corrosion resistance.

- Q:What are the main applications of special steel in the power storage industry?

- Special steel is widely used in the power storage industry for various applications. One of the main uses is in the manufacturing of battery components, such as battery casings, terminals, and connectors, due to its excellent corrosion resistance and high strength. Special steel is also utilized in the production of power transmission and distribution equipment, including transformers, generators, and turbines, where its superior mechanical properties and durability ensure reliable and efficient power generation and transmission. Additionally, special steel is employed in the construction of power storage structures, such as tanks and containers, providing long-lasting protection against environmental factors and maintaining the integrity of stored energy.

- Q:How does aluminum contribute to the properties of special steel?

- Special steel commonly incorporates aluminum as an alloying element to bolster its properties. The addition of aluminum yields multiple enhancements. Firstly, the inclusion of aluminum elevates the strength of the steel by creating a fine dispersion of aluminum nitride particles within the steel matrix. These particles act as barriers that impede dislocation movement, hindering steel deformation and amplifying its strength. Consequently, the steel becomes more resistant to mechanical stresses, thereby augmenting its load-bearing capacity. Secondly, aluminum also boosts the steel's corrosion resistance. It forms a protective oxide layer on the steel's surface, acting as a barrier against corrosive agents. This oxide layer prevents the steel from oxidizing, rusting, and deteriorating over time, thereby rendering it more durable and long-lasting in various environments. Moreover, aluminum can enhance the machinability of special steel. Its presence in the steel composition reduces the steel's tendency to work harden during machining operations. Consequently, cutting, drilling, or shaping the steel becomes easier, resulting in improved productivity and reduced tool wear. Furthermore, aluminum contributes to the heat resistance of special steel. With its high melting point and excellent thermal conductivity, aluminum aids in maintaining the steel's structural integrity at elevated temperatures. This renders aluminum-steel alloys suitable for applications demanding high-temperature resistance, such as those in the aerospace and automotive industries. In conclusion, aluminum plays a significant role in enhancing the properties of special steel. It bolsters strength, corrosion resistance, machinability, and heat resistance, making it a versatile material applicable in various fields.

- Q:How is stainless steel used in food processing?

- Stainless steel is widely used in food processing due to its exceptional properties such as corrosion resistance, durability, and hygiene. It is used to manufacture various equipment like storage tanks, mixing vessels, piping systems, and food preparation surfaces. Stainless steel's non-reactive nature prevents contamination and ensures food safety, while its smooth surface allows for easy cleaning and maintenance. Additionally, its strength and heat resistance make it suitable for high-temperature processes in food processing plants.

- Q:What are the properties of magnesium alloys?

- Magnesium alloys possess several important properties. They have a low density, making them lightweight and ideal for applications where weight reduction is crucial. They exhibit high strength-to-weight ratio, which makes them strong and durable. Magnesium alloys also have good heat dissipation properties, making them suitable for applications that require efficient cooling. They have excellent corrosion resistance, particularly when properly coated or treated. Additionally, magnesium alloys demonstrate good machinability and can be easily formed into various shapes and components.

- Q:How does special steel perform in high-temperature creep?

- Special steel is specifically designed to perform well in high-temperature creep conditions. It possesses superior strength, resistance to deformation, and stability at elevated temperatures, making it highly suitable for applications where prolonged exposure to high temperatures and constant stress is expected. Its unique composition and heat treatment processes enable it to maintain its mechanical properties and resist deformation or failure for extended periods under these extreme conditions.

- Q:What are the different methods of protecting special steel against corrosion?

- There are several methods available for protecting special steel against corrosion. Some of the commonly used methods include: 1. Coating: Applying a protective coating on the surface of the steel is one of the most effective ways to prevent corrosion. This can be done through various techniques such as hot-dip galvanizing, electroplating, or painting. Coatings act as a barrier, preventing moisture and corrosive substances from coming into contact with the steel. 2. Cathodic protection: This method involves the use of a sacrificial anode or an impressed current to protect the steel. In sacrificial anode cathodic protection, a more reactive metal is connected to the steel, which corrodes instead of the steel. On the other hand, impressed current cathodic protection uses an external power source to provide a continuous flow of electrons, preventing the corrosion process. 3. Alloying: Special steel can be alloyed with specific elements to enhance its resistance to corrosion. For example, stainless steel contains chromium, which forms a passive oxide layer on the surface, protecting it from corrosion. Similarly, adding elements such as nickel, molybdenum, or copper can improve the corrosion resistance of the steel. 4. Passivation: Passivation is a chemical process that involves treating the steel with an acid solution to remove any impurities from the surface. This process promotes the formation of a protective oxide layer, which prevents further corrosion. 5. VCI (Volatile Corrosion Inhibitors): VCI compounds are chemicals that release vapors, which form a protective layer on the surface of the steel. This layer acts as a barrier against moisture and corrosive substances, effectively preventing corrosion. 6. Proper maintenance and cleaning: Regular maintenance and cleaning of the steel surface can significantly extend its lifespan and prevent corrosion. Removing dirt, debris, and corrosive substances from the surface reduces the likelihood of corrosion. It is important to note that the choice of method depends on various factors such as the type of steel, the environment it will be exposed to, and the expected lifespan. Consulting with corrosion experts or engineers can help determine the most suitable method for protecting special steel against corrosion.

- Q:How does the carbon content affect the properties of special steel?

- The carbon content plays a crucial role in determining the properties of special steel. Higher carbon content tends to enhance its hardness, strength, and wear resistance. This is because carbon forms interstitial solid solutions with iron, creating stronger and more stable iron carbides. On the other hand, lower carbon content leads to increased ductility and toughness. The carbon content also influences the steel's ability to be heat-treated, affecting its response to processes like quenching and tempering. Therefore, controlling the carbon content allows manufacturers to tailor the properties of special steel to meet specific application requirements.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

TMT Reinforced Bars 10mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords