Tinplate, SPTE for Cans making, competitive price

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

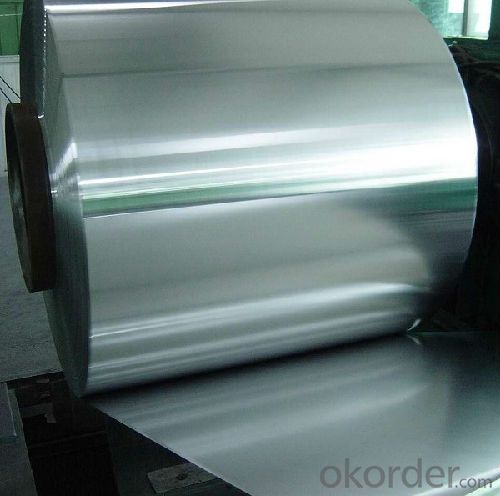

Prime quality Tinplate Sheet and Coil for Cans Making

1.Structure of Description

Electrolytic Tinplate Sheets is one of the metal packing materials, which is widely used for making painting cans ,chemical package cans , electrical cable ,battery and metal printing etc. For caps, there are some customers also need TFS, if you have some demand for TFS,also can contact with us.

2. Main Features

Steady and high quality

Fast shipment

Good experience for export work

For the surface, Plate uniform in thickness,uniform and smooth tin coating, without flaws,rusts,scratch,wave,nick of tin coating etc.

Specifications

| Type | MR, SPCC |

| Temper(BA&CA) | T1-T5, DR8-DR10 |

| Coating | 1.1-8.4g/m^2 |

| Thickness& Tolerance | 0.15-0.5mm(tolerance +/-0.01mm) |

| Width& Tolerance | 600-1010mm(tolerance +2/-0mm) |

| I.D | 508mm |

| Coil weight | 3-10MT |

| Passivation | 311 |

| Oiling | DOS |

| Surface finish | Bright, stone |

| Package | Seaworthy Export Standard Wooden Pallet |

| Standard | ISO 11949 -1995, JIS G3303,ASTM A623, BS EN 10202 |

| Special specifications are available on customers' requirements | |

Application

Tinplate is widely used for making all types of containers, electrical machinery parts and many other products.

- Chemicals and painting cans

- Dry food cans, such as fancy cans, biscuit cans, milk powder cans, tea cans,

- Sea food cans

- Crown corks, easy open ends

- Electrical machinery parts

- Bakeware and household kitchen parts

FAQ

CNBM Introduction

China National Building Materials Group Cooperation, as a leading state-owned enterprise with 3 billion USD and 40,000 staff in China, CNBM was established in 1984 under the administration of the state-owned Assets Supervision and Administration commission of the State Council. There are over 300 surbordinate factories and companies in our group; 2 public listed companies in Hong Kong, 4 Public listed companies in China mainland; 11 publicly listed companies in which CNBM has a substantial percentage of shares. The business scope of CNBM covers from Manufacturing and sales of building materials to scientific research and design, engineering, import and export trading.

On July 7th, 2011, Fortune Magazine established Fortune Global 500 ranking on its website, and CNBM Group was listed for the first time, with a ranking of 485.

CNBM International Corporation

CNBM International Corporation, as an important import and export platform of CNBM Group, enjoys competitive advantages in importing and exporting of building materials as well as complete sets of machinery and equipments, engineering, and project contracting.

CNBM Branch Offices

In order to promote the business connection, CNBM has established branches and offices in lots of foreign countries, such as USA, GERMANY, UAE, SAUDI ARABIA, IRAN, JORDAN, LIBIA,ETHIOPIA, INDONESA, INDIA,VIETNAM,RUSSIA,KAZAKHSTAN. It is very helpful for the communication and after- sale services.

Factory Introduction

CNBM as one of the largest suppliers in tinplate industry, offers clientss prime quality tinplate in both coil and sheets. With multi-plants and fully integraded production, the annual capacity of tinplate is 400,000MT.

To ensure the high quality if the tinplate, CNBM owns complete equipment series.

- Reversing cold rolling machines: 14 sets

- Continuous rolling machines: 2 sets

- BA furnaces: 50

- CA line: 1

- Tinplate production line: 2

- SA& DA reduced tinplate sheet: Available

CNBM also produce other steel products, such as cold-rolled steel, hot dip galvanized steel, color coated steel and tin free steel coils and sheets.

- Q:What are the health and safety concerns associated with tinplate?

- Some health and safety concerns associated with tinplate include potential exposure to tin, which can cause respiratory issues and skin irritation if inhaled or in contact with the skin for prolonged periods. Additionally, the coatings used on tinplate may contain harmful chemicals like bisphenol A (BPA), which has been linked to various health problems. It is important to handle and use tinplate products with caution, ensuring adequate ventilation and avoiding direct contact with the coating.

- Q:What are the weight advantages of using tinplate?

- One of the weight advantages of using tinplate is its lightweight nature. Tinplate is made of thin sheets of steel coated with a layer of tin, which makes it lighter compared to other metal packaging materials. This lightweight feature allows for easier transportation, storage, and handling, reducing overall costs and increasing efficiency in various industries.

- Q:How does tinplate compare to plastic-coated steel in terms of properties and applications?

- Tinplate and plastic-coated steel have different properties and applications. Tinplate is known for its corrosion resistance, excellent formability, and ability to hold a tight seal. It is widely used in the packaging industry for products like food cans and aerosol containers. On the other hand, plastic-coated steel provides superior chemical resistance and impact strength. It finds applications in industries like automotive, construction, and electrical, where durability and resistance to environmental factors are crucial. Overall, while tinplate is preferred for its sealing properties in packaging, plastic-coated steel is favored for its durability and chemical resistance in various industrial applications.

- Q:What are the quality control measures for tinplate production?

- Quality control measures for tinplate production typically involve a combination of inspections, tests, and process controls. These measures include visual inspections to check for defects like scratches, dents, or uneven coating, as well as dimensional checks to ensure the tinplate meets specified thickness and width requirements. Additionally, chemical composition analysis is often performed to verify the tinplate's composition and adherence to standards. Coating adhesion and corrosion resistance tests are also conducted to ensure the tinplate's durability. Overall, quality control measures aim to ensure that tinplate production meets the desired quality standards and customer requirements.

- Q:And what are the main packing materials?

- Maguchi Tetsumi the tank is to sheet metal for tank type packaging materials by crimping, bonded resistance welding processing, by the tank body and the tank bottom and the tank cover is composed of three parts, a tank body packaging container joint, tank body and tank bottom and tank capping.

- Q:How is tinplate different from other types of steel?

- Tinplate is different from other types of steel primarily because it has a thin layer of tin coating on its surface. This coating provides tinplate with exceptional corrosion resistance, making it ideal for packaging food and beverages. Additionally, the tin coating gives tinplate a shiny appearance and enhances its solderability, making it suitable for various industrial applications.

- Q:How does tinplate perform in microwave ovens?

- Tinplate is not suitable for use in microwave ovens as it can cause sparks and potentially damage the oven.

- Q:What is the thickness range of tinplate?

- The thickness range of tinplate typically varies from 0.13mm to 0.50mm.

- Q:Can tinplate be used for packaging products with specific storage requirements?

- Yes, tinplate can be used for packaging products with specific storage requirements. Tinplate is known for its excellent protective properties, including resistance to moisture, oxygen, and light, which makes it suitable for preserving the quality and freshness of various products. Additionally, tinplate is highly durable and can withstand temperature variations, making it ideal for packaging products with specific storage needs.

- Q:What are the key factors to consider when choosing tinplate for packaging?

- When choosing tinplate for packaging, key factors to consider include the thickness and strength of the material, its corrosion resistance, the ease of printing and branding on the surface, the overall cost, and its sustainability and recyclability. These factors ensure that the tinplate packaging will provide adequate protection, maintain product quality, and align with environmental considerations.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Tinplate, SPTE for Cans making, competitive price

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords