Tinplate in Sheets and Coils for Cans Packing in good quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 7000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Electrolytic Tinplate in Sheets and Coils for Cans Packing Description

Due to Tinplate packaging`s good seal, nature, dark, robustness and unique decorative metal charm, it has a wide range of coverage in the packaging container industry,and common international packaging varieties. With a variety of CC tinplate material, DR materials, chrome plated and constantly enrich and promotion and development of packaging products and technology, tinplate packaging has promoted with innovation.

Because of its strong antioxidant and diverse styles, beautifully printed, tinplate containers are very popular and loved by customers, and they are widely used in food packaging, pharmaceutical packaging, commodity packaging, instrumentation, packaging, industrial packaging and so on.

With the continuous improvement of tinplate printing technology and processing technology, tinplate packaging has developed more widely.

2.Main Features of the Electrolytic Tinplate in Sheets and Coils for Cans Packing

Appearance – Electrolytic Tin Plate is characterized by its beautiful metallic luster. Products with various kinds of surface roughness are produced by selecting the surface finish of the substrate steel sheet.

Paintability and printability – Electrolytic Tin Plates have excellent paintability and printability. Printing is beautifully finished using various lacquers and inks.

Formability and strength – Electrolytic Tin Plates have got very good formability and strength. By selecting a proper temper grade, appropriate formability is obtained for different applications as well as the required strength after forming.

Corrosion resistance – Tinplate has got good corrosion resistance. By selecting a proper coating weight, appropriate corrosion resistance is obtained against container contents. Coated items should meet 24 hour 5 % salt spray requirement.

Solderability and weldability – Electrolytic Tin Plates can be joined both by soldering or welding. These properties of tinplate are used for making various types of cans.

Hygienic – Tin coating provides good and non toxic barrier properties to protect food products from impurities, bacteria, moisture, light and odours.

Safe – Tinplate being low weight and high strength makes food cans easy to ship and transport.

Eco friendly – Tinplate offers 100 % recyclability.

Tin is not good for low temperature applications since it changes structure and loses adhesion when exposed to temperatures below – 40 deg C.

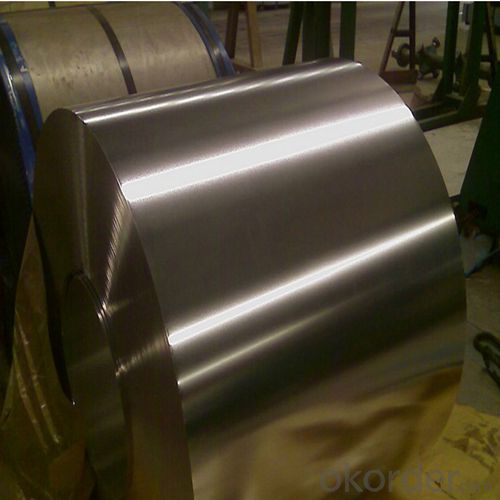

3.Electrolytic Tinplate in Sheets and Coils for Cans Packing Images

4.Electrolytic Tinplate in Sheets and Coils for Cans Packing Specification

Standard | ISO 11949 -1995, GB/T2520-2000,JIS G3303,ASTM A623, BS EN 10202

|

Material | MR,SPCC |

Thickness | 0.15mm - 0.50mm |

Width | 600mm -1150mm |

Temper | T1-T5 |

Annealing | BA & CA |

Coil Inner Diameter | 508mm |

Weight | 6-10 tons/coil 1~1.7 tons/sheets bundle |

Passivation | 311 |

Oil | DOS |

Surface | Finish,bright,stone,matte,silver |

5.FAQ of Electrolytic Tinplate in Sheets and Coils for Cans Packing

- How are the Electrolytic Tin Plates specified?

The Electrolytic Tin Plates are specified as per the steel base, extent of tempering, the coating weight, annealing method and the surface finish.

- How many types there are for base steels?

The base steels are of three types: Type MR, L, D

- Q:What is the shelf life of tinplate canned goods?

- The shelf life of tinplate canned goods can vary depending on the specific product and storage conditions. Generally, these canned goods have a shelf life of 2 to 5 years when stored in a cool, dry, and dark place. However, it is recommended to check the expiration date on the can and discard any cans that are bulging, leaking, or have a foul odor as they may be spoiled.

- Q:What are the disadvantages of using tinplate in packaging?

- One disadvantage of using tinplate in packaging is that it can be more expensive compared to alternative packaging materials such as plastic or cardboard. Additionally, tinplate is prone to corrosion, which can compromise the integrity of the packaging and lead to product spoilage. It is also heavier than other materials, which can increase shipping costs and carbon footprint. Finally, tinplate is not as easily recyclable as some other packaging materials, contributing to environmental concerns.

- Q:What are the industry standards for tinplate?

- The industry standards for tinplate typically include specifications regarding the tin coating thickness, base metal quality, surface finish, dimensional tolerances, and other relevant characteristics. These standards are established by organizations such as the International Organization for Standardization (ISO) and the American Society for Testing and Materials (ASTM), ensuring consistency and quality across the tinplate industry.

- Q:How does tinplate perform in terms of odor resistance?

- Tinplate generally performs well in terms of odor resistance due to its non-reactive nature and the protective coating of tin, which helps prevent any odors from permeating through the metal.

- Q:How do you clean the dust and trace oil on tin containers?

- Solvent cleaning: This is the traditional way, from the middle of the Qing Dynasty period have been used, it is with a cleaning agent such as solvent, steam coal, white oil (to waterlogging, water purifier, hydrocarbon and so on).

- Q:What are the main uses of tinplate?

- Tinplate is primarily used in the packaging industry for food and beverage containers, such as cans for canned foods, beverages, and aerosol products. It provides a protective coating to prevent corrosion and maintains the quality and freshness of the products. Additionally, tinplate finds applications in the manufacturing of various household items, decorative products, and electronic components.

- Q:What are the main applications of tinplate in the cosmetics industry?

- Tinplate is primarily used in the cosmetics industry for packaging purposes. It provides a durable and protective barrier that safeguards cosmetic products from external elements, such as light, moisture, and air, thereby extending their shelf life. Additionally, tinplate offers an attractive and visually appealing packaging solution, allowing brands to enhance their product's presentation and create a unique brand identity.

- Q:How does tinplate contribute to the presentation of jewelry?

- Tinplate is commonly used for jewelry packaging due to its durability, versatility, and aesthetic appeal. Its smooth and shiny surface provides an attractive backdrop that enhances the visual presentation of jewelry. Additionally, tinplate can be easily shaped into various forms, allowing for unique and eye-catching packaging designs that effectively showcase the beauty and elegance of the jewelry inside. The use of tinplate also adds a touch of sophistication and luxury to the overall presentation, making it an ideal choice for premium and high-end jewelry brands.

- Q:How is tinplate cut and formed into different shapes?

- Tinplate is commonly cut and formed into different shapes using a variety of methods such as shearing, blanking, stamping, and deep drawing. These processes involve using specialized machinery and tools to cut the tinplate into desired shapes or form it into specific structures.

- Q:Why do tin tins rust easily when they are opened?

- The tinplate is of poor quality and the tin is not enough

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Tinplate in Sheets and Coils for Cans Packing in good quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 7000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords