Tinplate and Tin free steel for food cans and chemical cans

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 40900 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

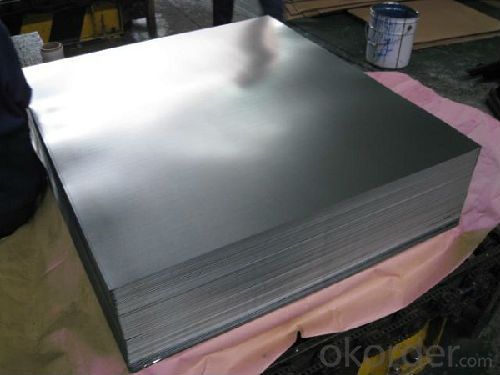

Prime Quality Tinplate Sheets Details

1.Structure of Description

Electrolytic Tinplate Sheets is one of the metal packing materials, which is widely used for making painting cans ,chemical package cans , electrical cable ,battery and metal printing etc. For caps, there are some customers also need TFS, if you have some demand for TFS,also can contact with us.

2. Main Features

Steady and high quality

Fast shipment

Good experience for export work

For the surface, Plate uniform in thickness,uniform and smooth tin coating, without flaws,rusts,scratch,wave,nick of tin coating etc.

Minumum Order Quantity: 25 MT Loading Port:China Main Port

Annual Capacity: 400,000MT Payment Terms:TT or LC

Product Specifications:

Prime Quality Tinplate Sheets Usage and Applications

Prime Quality Tinplate Sheets Specifications

Standard : GB2520-2000 ,JIS G3303

Steel type : SPCC

Coating : 2.8/2.8

Surface: Bright, Stone ,

Thickness:0.18

Width :600MM~1000MM

Temper : T1~T5

Package: tinplate wrapped completely with an inner cover of plastic or waterproof papers with vorners protected with metal angels.

Applications

Chemicals and painting cans

Dry food cans, such as fancy cans, biscuit cans, milk power cans, tea cans

Liquid food cans, such as edible oil cans, beverage cans, Tomato paste cans

Sea food cans

Crown corks, easy open ends(EOE)

Electrical machinery parts

Bakeware and household kitchen parts

FAQ

A. What is the package of tinplate? (Referred as below)

For sheets, thin plastic film + rust-proof paper + metallic cover + metallic angles+ steel band strips + fumigated wooden pallet.

For coil, thin plastic film + rust proof paper + metallic cover + steel band strips + fumigated wooden pallet

B. The surface of tinplate could you supply?

Stone finish, Bright finish, Matte finish, Silver finish

- Q:Can tinplate be used for packaging perishable goods?

- No, tinplate is not suitable for packaging perishable goods as it is not airtight and does not provide adequate protection against moisture and oxygen, which can lead to spoilage of perishable items.

- Q:What are the main properties of tinplate?

- Tinplate is primarily known for its corrosion resistance, durability, and versatility. It is a thin steel sheet coated with a layer of tin, which provides a protective barrier against rust and oxidation. This makes tinplate suitable for packaging various food and beverage products. Additionally, its malleability allows for easy shaping and forming, making it ideal for intricate designs and embossing. Tinplate also exhibits excellent solderability, making it a preferred material for manufacturing cans, containers, and other metal products.

- Q:How does tinplate contribute to the overall aesthetics of packaging?

- Tinplate contributes to the overall aesthetics of packaging by adding a sleek and premium look to products. Its smooth surface and high reflectivity enhance the visual appeal, making the packaging stand out on shelves. Additionally, the ability to print vibrant colors and intricate designs on tinplate further enhances the attractiveness of the packaging, making it visually appealing to consumers.

- Q:What are the main challenges in tinplate coating thickness control?

- The main challenges in tinplate coating thickness control involve achieving uniformity and accuracy throughout the entire coating process. This requires overcoming issues such as variations in tinplate surface quality, ensuring consistent application of the coating material, and accurately measuring and monitoring the thickness of the coating. Additionally, maintaining control over the coating parameters and adjusting them appropriately to accommodate different tinplate grades and production conditions is also a challenge. Overall, achieving precise and consistent coating thickness control is crucial for ensuring product quality and meeting customer specifications.

- Q:How is tinplate affected by different types of dairy products?

- Tinplate, a type of steel coated with a thin layer of tin, can be affected by different types of dairy products in terms of corrosion. Dairy products, particularly those with high acidity or salt content, can cause the tin coating to corrode over time. This can result in changes in the taste, odor, and quality of the dairy products stored in tinplate containers. Therefore, proper packaging and storage conditions need to be ensured to maintain the integrity of tinplate when storing dairy products.

- Q:What are the main innovations in tinplate production and use?

- One of the main innovations in tinplate production is the introduction of continuous annealing, a process that allows for a more efficient and consistent production of tin-coated steel sheets. This method not only reduces production time and energy consumption but also improves the quality of the final product by ensuring a more uniform coating. In terms of use, the development of tinplate packaging has been a significant innovation. Tinplate cans and containers have become widely used in the food and beverage industry due to their excellent preservation properties and ability to protect the contents from external factors such as light, moisture, and oxygen. Additionally, manufacturers have also started using tinplate in various other sectors like electronics, automotive, and construction due to its durability, corrosion resistance, and versatility. Overall, these advancements in production and use have greatly expanded the applications and benefits of tinplate.

- Q:Cookies with tinplate packaging has what advantage?

- Shapes: tinplate cans can be made into various shapes according to different needs, such as cans, cans, cans, circular elliptical horseshoe and trapezoid etc, can satisfy the different needs of product packaging, and the packaging container more change, promote sales.

- Q:What are the different sizes and shapes of tinplate packaging available?

- Tinplate packaging comes in various sizes and shapes to cater to different product requirements. Some common sizes include rectangular tins, round tins, and square tins. These sizes can range from small, pocket-sized tins to larger ones suitable for bulk packaging. Additionally, tinplate packaging can also be customized to specific shapes and dimensions, allowing for unique and eye-catching designs.

- Q:What are the main challenges in tinplate recycling?

- The main challenges in tinplate recycling include the separation of tinplate from other materials, as well as the need for specialized recycling facilities and processes. Additionally, the collection and sorting of tinplate waste can be challenging due to its diverse sources and varied forms, such as cans, containers, and packaging.

- Q:How does tinplate perform in terms of resistance to humidity?

- Tinplate performs exceptionally well in terms of resistance to humidity. The tin coating applied to the steel substrate creates a barrier that prevents moisture from corroding the underlying metal. This makes tinplate highly resistant to the damaging effects of high humidity, ensuring its durability and longevity in various applications.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Tinplate and Tin free steel for food cans and chemical cans

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 40900 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords