TIN FREE STEEL PLATE

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

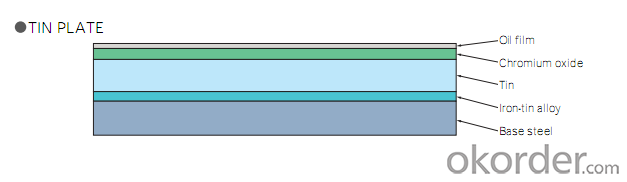

Coating structure:

- Q:What's the head iron?

- The name "tinplate", also known as tin plated iron, is the common name for tin plated steel sheet. The English abbreviation for "SPTE" refers to cold-rolled low carbon steel sheet or strip coated with commercially pure tin on both sides. Tin plays a major role in preventing corrosion and rusting. It will be the steel strength and formability and corrosion resistance of tin soldering, and beautiful appearance with a material, corrosion resistant, non-toxic, high strength and good ductility properties.

- Q:How does tinplate packaging contribute to product tamper resistance?

- Tinplate packaging contributes to product tamper resistance by providing a strong and durable barrier that is difficult to breach without leaving visible signs of tampering. Its robust construction and tamper-evident features such as seals, closures, or breakable seals make it challenging for unauthorized individuals to access the product undetected.

- Q:How does tinplate affect the overall product visibility?

- Tinplate enhances the overall product visibility by providing a glossy and reflective surface that attracts attention. Its smooth and bright finish allows for excellent printability, making it ideal for branding and product information displays. The reflective properties of tinplate also contribute to the product's visibility on store shelves, catching the eye of potential customers and increasing its overall appeal.

- Q:What are the different printing methods used on tinplate?

- There are several different printing methods used on tinplate, including lithography, screen printing, and digital printing. These methods allow for high-quality and detailed designs to be printed onto tinplate surfaces, making them ideal for packaging and decorative applications.

- Q:How can tinplate be rustproof? Products must not be oil

- It has good salt spray resistance, drainage performance and resistance to hand sweating. It has a long time of rust prevention.

- Q:How does tinplate compare to glass packaging?

- Tinplate packaging offers several advantages over glass packaging. Firstly, tinplate is significantly lighter than glass, making it easier and more cost-effective to transport. Secondly, tinplate is more durable and less prone to breakage, reducing the risk of damage during handling and storage. Additionally, tinplate provides better protection against light and oxygen, ensuring the contents inside remain fresh and unaffected. Lastly, tinplate is highly recyclable, making it a more sustainable choice compared to glass packaging.

- Q:Tin, tin plated iron. Why can't we get white wine?

- Passivation of the tinplate, if further coating, will be very good corrosion resistance, but these coatings are not resistant to alcohol.In short, tinplate is afraid of water, but also afraid of alcohol, so it can not be loaded white wine.

- Q:What do tinplate do?

- Material to distinguish between SR (Pu Tongcai) and DR (two rolled material)Annealing is distinguished by CA (continuous annealing), BA (bell annealing), different annealing, and different hardness. Corresponding to different processing properties.

- Q:How has tinplate evolved over the years?

- Tinplate has evolved significantly over the years with advancements in production techniques and technology. Initially, tinplate was made by hand, resulting in inconsistent quality and limited production. However, with the development of mechanized processes, tinplate production became faster, more efficient, and cost-effective. Additionally, improvements in tin coating methods have enhanced the durability and corrosion resistance of tinplate. Nowadays, tinplate is produced using high-speed mills and advanced coating technologies, ensuring consistent quality, customization options, and increased market demand.

- Q:What are the advantages of using tinplate for shipping containers?

- There are several advantages of using tinplate for shipping containers. Firstly, tinplate is highly resistant to corrosion, which ensures the longevity and durability of the containers, even in harsh marine environments. Secondly, tinplate offers excellent strength-to-weight ratio, making it a lightweight yet sturdy option for shipping containers. Additionally, tinplate is easy to form and shape, allowing for efficient manufacturing processes. Lastly, tinplate provides an effective barrier against moisture and oxygen, protecting the goods inside from damage during transportation.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

TIN FREE STEEL PLATE

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords