Tile Bond /Adhesive for construction chemicals

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 kg

- Supply Capability:

- 50000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Tile Bond /Adhesive

Tile bond is an adhesive mortar for installing all types of floor and wall tiles. It’s an unique mortar with chanracteristics of high sticking power, low water absorption, high chemical resistant with long life and easy tile installation. It may be applied to new concrete, old concrete, cement plaster, brick and block works.

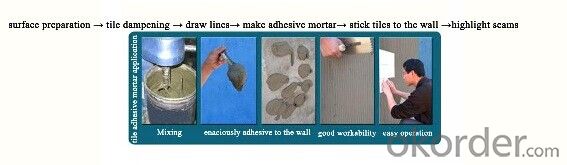

Application

1. Mixing: The mixing ratio with water is 1 to 4. Except for water, no any other cement, sand or admixture allows to be added,.

2. Preparation: Add a certain amount of water into a clean barrel, then pour calculated adhesive mortar into it, mixing until a evenly and lump-free paste achieved. Usually, stirring it for 3 to 5 minutes with stirring speed less than 1000 times per minute. Then stand for 2 to 3 minutes, restirring it before applying.

3. Using time: The prepared adhesive mortar would better be used up within 45 minutes.

Cautions

1. Make the concrete surface rough with depth in 5~10 mm with notched trowel, the gouge should be about 30mm.The concrete surface should be free from dust, mortar, grease, loose plaster.

2. Moisture the floor or wall surface before placing tile.

3. Lay the tile with good pressure to ensure good contact with adhesive.

4. To fill the tile gaps using white cement grout after placing 2 to 3 hours, the ratio of white cement with sand is 1 to 1. Make sure the grouting is full and evenly between the tile gaps. Then, clean the tile surface with moisture sponge.

5. The initial compressive setting remnant adhesive mortar can be applied again while add water and mixed with new prepared adhesive mortar.

6. Sun shading equipment should be used when the environmental temperature is higher than 35℃to avoid tile materials dehydration. The lowest applying temperature should be above 4℃..

Coverage

1.5kg per square meter for mosaics with a 4mm notched trowel.

2.5kg per square meter for ordinary ceramics with a 6.5mm notched trowel.

4.0kg per square meter large tiles with a 10mm notched trowel.

Packaging & Storage

Tile bond/adhesive is packed in 30kg bag. The shelf life is 12 months in original sealed bags in dry condition.

- Q:Jiangbei District Guanyinqiao near where to buy tiles? Paste the kitchen tiles, the price is how much? Can specifically specify the place to sell tiles.

- If you want to tiling, it is best to negotiate with the landlord. The owner of the tiling, then your monthly crossroads rent. Tiled, but also bought a brick and found that workers are not cheap. , But the bathroom paving the way, the amount of work is too small, few people are willing to give you the price of paving more expensive than usual, the house is man, people do not necessarily make your shop because, after all, tiles, wood flooring. If you want to change, later words, but also ruthless and cumbersome. Published a cheap, down to you

- Q:The square of the same hexagonal tiles is laid in the same way as shown in the figure (in the annex). The middle hexagonal tiles are marked as A and are defined as the first group, with six pieces of the same size Square hexagonal tiles, defined as the second group, in the second group with the same size of the hexagonal tiles to cover, defined as the third group, ..., in this way paved with the existing 2007 block Tiles can be filled with up to () groups, at this time there are remaining () pieces of tiles.

- Passing on the issue of no interest, the first floor of your rolling far point, do not know do not call, ceramic tiles Guangdong registered trademark, even if the production in Tibet can also play Guangdong Foshan, you can explain to me how to distinguish it? And Marco Polo is the characteristics of antique tiles, the industry people understand, he is the leader of antique brick, do not know how to copy

- Q:Will the building shop shop open a brick shop?

- Can be, but mainly on their own run list. If open to the market inside the customer to find the probability of how much more.

- Q:Our community elevator staircase staircase all did not paste tiles, developers say that the fire stairs Will the fire stairs must set fire doors. Will the fire staircase whether to set fire doors, fire stairs have any other requirements, our community elevator staircase staircase all the tiles are not posted, the developer said that the fire stairs, and now the stairs of the stairs do not stick tiles more ugly ah is not Live 2 days a day, down for many years, then the stairs can be called stairs? We are looking for developers to solve this problem, we give some suggestions ... ...

- Hello, I'm doing fire engineering. Hope to help you. First, the fire staircase is sure to set fire doors, and the material is also required, of course, can not be wood, specifically to see the fire norms it Second, paste the tile, which is not required in the fire code, the owner decided, of course, you are the buyer, agreed to upstairs said, you still need to check your contract inside a copy of the annex: " Here is the staircase is what kind of provisions or instructions, if not written above, then find developers is useless. I remember when I bought a house because the skirt is not the kind of contract written on the tile, but also and people downtown trouble, the final result is the tile has been posted, so make up the difference plus the appearance of beautiful cost.

- Q:When did these terms begin, which literature appeared in the country's construction?

- There is no mandatory requirement to leave the tiles

- Q:Hello there! My house is made of tiles to do the backdrop, what decoration side look good? Frame line or what

- With the background of the wall made of tiles very nice, almost every family have to do inside the TV wall, tile background wall can be decorated with wood or gypsum material is very nice to see ah, the main role of the TV backdrop

- Q:This washbasin, how to live on the bathroom tiles

- Adhesive with porcelain white glass, fixed 12 hours is good.

- Q:I am praying, decorating to buy tiles. Near what the city of building materials, as well as we recommend a brand of ceramic tile brand too much

- You can look at the new South Wyatt ceramic brand

- Q:ust do ps inkjet tile color, and some do not quite understand, such as gray, replace the file, channel, there are color adjustment, do this line? Can you elaborate? Thank you

- Grayscale is the color mode. Replace the file, that is, a part of the picture for the color of what, replace the filter bar. Is used in conjunction with the positive stack. The channel is commonly used in matting, RGB colors. Color, then you are talking about an object attached to a different color, this is the definition of the pattern to use. Detailed picture: 1, grayscale. Is the choice of material color, such as: rgb is the computer color, cmyk is printed color, gray is all the background are gray.

- Q:At first thought that the window is not sealed on the edge, and later on the edge of the window irrigation, but still the case, what remedial. Interior has not painted I was not thinking about the windows, maybe the walls ah

- 1. In the external walls of tiles painted waterproofing agent (glazed and brick are painted, until the basic dry, diluted with water cloth acetate cloth Sassafras clean surface superfluous waterproofing agent, does not affect the waterproof and appearance) 2. Interior wall with water dilution waterproofing agent sweep 1 to 2 times, and finally paint. This is an effective remedy because the main component of the water repellent (js) is sodium silicate, where the aqueous solution of sodium silicate penetrates into the ceramic tile and encounters an acid to produce silica gel.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Tile Bond /Adhesive for construction chemicals

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 kg

- Supply Capability:

- 50000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords