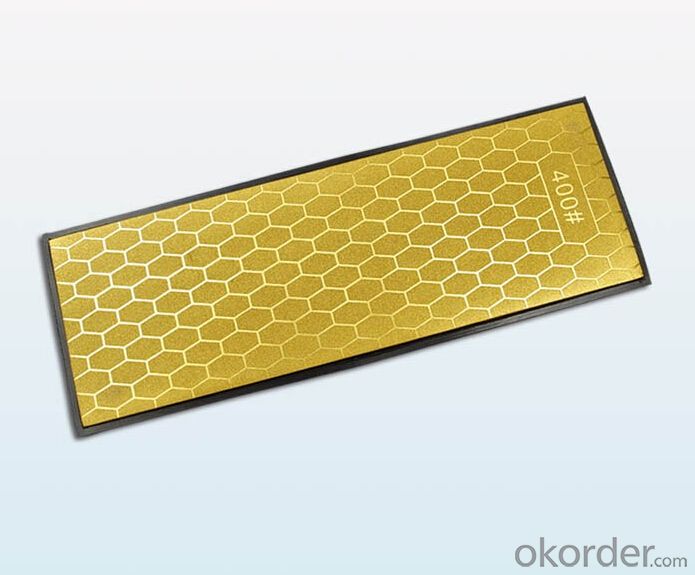

Ti-coated Diamond Stone for Professional Knife Sharpening

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 20000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ti-coated Diamond Stone for Professional Knife Sharpening

Stone Material:Ti-Coated Stainless Steel

Holder Material:plastic/stainless steel

Stone Size : 180*70*8mm

Weight: 750g

Diamond Grit:400#/1000#

Model no:LX-1304

Usage:Woodworking tools sharpening

OEM:YES

Package:color box

Diamond Whetstone Description:

Diamond coated stainless steel whetstone a durable, with a high hardness, excellent self-sharpening, grinding power, high efficiency, is an acid corrosion, high temperature and other characteristics on both sides of the duplex Whetstone different granularity from the will of each particle size Whetstone different grinding effect, so a Whetstone has two grinding performance, affordable and versatile.

Diamond Whetstone Scope:

Widely used in kitchen knives and garden tools, woodworking tools.

Diamond Whetstone Features:

1. Excellent sharpening performance

2. Double sided diamond design as 400Grit for coarse sharpen & 1000Grit for fine honing

3. Clear plastic cover protects the stone, molded plastic base with non-slip feet for safety

4. Oval hole design to collect and hold metal chippings

5.The high quality plastic holder keep the stone steady when sharpening,also protect your hand.

Diamond Whetstone Show

Using Instruction

1. Place the stone on a non-slip worktop and make sure the surface is flat.

2. Complete one or both of the following steps depending on how blunt the blades is.

Step1. for coarse sharpening: Used to repair badly damaged blade, suitable for a blunter knife.

Start by using the coarse 400 grit of the stone, move the blade back and forth over the stone at an angle of 10 - 30 ° by using light pressure.

Generally sharpen the tools with coarse stage every six months or as required.

Step 2. for fine honing; always finish off with this step to remove any burrs that result from the re-edging and rough honing process.

Using the 1000 grit of the stone, move the blade back and forth over the stone at an angle of 10 - 30 ° by using gentle pressure.

It is recommended to do it approximately once a week.

3. Clean the knife with the water or wiper and dry it after use and clean the knife sharpener with banister brush.

Caution:

1. Do not use the knife sharpener to sharpen serrated blades.

2. It would be much better to use with sharpening oil or water

4. Please don’t put sharpener in dishwasher or water

5. Please put the knife sharpener and knife beyond the reach of children to avoid any accidents.

FAQ

What is Diamond Sharpener

Our main products are Diamond Whetstone/Diamond Kitchen Knife/Electrical Knife/Ceramic Sharpening Rod/Steel Sharpening Rod/Oil Stone/Skate Sharpener/Outdoor Pocket Sharpener .

Sharpener are widely used for Kitchen/Garden/Woodworking Tools,we can find it everywhere.there are various kinds sharpener for different use.the main materials are Diamond Steel/Ceramic/Alumina Corundum.

How to Use

First ensure the power switch of the sharpener is disconnected; then connect the adapter and power supply; last turn on the switch of the sharpener. (a. connected the adapter b. connect the power supply c. turn on the power switch)

1)Coarse sharpening

Coarse sharpening part is for putting the first edge of knife and repairing serious-damaged knives.

2)Fine Honing

Under normal circumstances, it is suggested to use weekly or daily, to keep your blade sharp at any time.

What Service we can offer?

We aim to offer the best Price&Products to all our customers.If you’re interested in we can send you our catalog by email,samples also allowed if necessary.

And we warmly welcome all your inquiry with required specifications!

- Q:With a fixed angle knife also used to use the kind of Zwilling two grooves directly on the top of the mill?

- You can choose to give some sharpening shop or business mill, I'd better recommend you go to the mill grinding mill, because you are estimated to buy the business far away. We have a few, they can be the best job, but he wouldn't pick up some one is afraid to wear, then this is the long Katana does not allow private edge, but their good grinding technology. Is it yourself grinding, need not much of anything is better, and I also have a lot of knives are collections but also some good-looking appearance, quality is not good cheap goods, what are, my knife is grinding. I would like to talk about some of my experience, it is necessary to prepare the crude stone is also a fine stone and a piece of stone, a piece of natural Whetstone, in the water and wipe the knife, which is not to say. (the natural stone could not get, we have to sell a lot, this is our town, bazaar, sell iron bazaar stalls only three dollars a piece of stone of the same size and, I have several pieces of it, you do not know that there is no one) a very simple method that small is the first rough stone first general a blade look is narrow, then fine grinding blade is stone basically, with the final natural Whetstone is fine, carefully grinding out a sharp edge, the last on the fine after the good words and shaving the sharp knife. If you think the stone slow, can be used for electric wheel or wheel angle grinder also, but it is not recommended to use the electric wheel, the control is not good I can't. Angle grinder can also be. The natural knife is very delicate with it after the original stone grinding will be worn are worn smooth, the last is to use the ancient grinding mill, but the technology must be better, this will depend on the maintenance practice of the Katana oil, such as sewing machine oil, gasoline, especially sewing oil easy to buy.

- Q:Sharpener good, advantages, disadvantages

- Is not good, it is recommended not to use, good knives are worn out, with the most primitive stone on the line

- Q:What is the better effect of sharpening and sharpening for the knife

- Knife effect is good, but life is not longThe grindstone is durable

- Q:Do you have a Tupperware sharpener?

- Can you imagine corrugated cardboard.You want to fold the cardboard, along the texture is very easy to fold, vertical texture is very difficult.The blade is very easy to wear.And often, a knife, the knife is the best point.It's done.

- Q:What is a sharpener? What is the specific working principle? What are the advantages and disadvantages?

- The knife sharpener is a scientific, practical, efficient and convenient sharpening tool. Applicable to all kinds of kitchen knives, which is characterized in that the traditional single knife to double knife, sharpening method, angle changed efficiency, cutting the most blunt no more than half a minute, and make it very sharp, its efficiency is really incomparable, the knife sharpener is for special material material processing refined, long service life, simple operation and cheap, it is an indispensable housewife good helper, not only the ideal is a knife wound

- Q:Which kind of brand is good

- Locating the sharpener, can also be used with, and grinding after not easily scratch the hand, I hope to help you!

- Q:Is it possible to use an ordinary whetstone? Will not damage the tool?

- Right, there is a special knife sharpener, or sharpened periodically better, if LZ do it yourself, ordinary grindstone, collocation Zwilling tool is not very good, may also damage the blade, anyway, my family is a special. If LZ does not want to spend money or too lazy to do it, you can go to the counter. Remember, oh, it's free and permanent!

- Q:Stainless steel kitchen knife blunt how to profit? I sharpen the knife sharpener seems more blunt

- Stainless steel knife also has its special knife sharpener, most of the knife is put in the design of a good card slot back and forth grinding can be a. Of course, there are many kinds of knife grinder, if it is a good knife, a good horse with a good saddle, but also to buy a good sharpener, in accordance with the instructions to do, are very useful.There is a sharpener, the butcher used, the effect is also good, sharpening immediately becomes faster, but maintaining the sharpness of the relatively short time.Of course, the most traditional grindstone also can grind stainless steel knife, but involves a lot of technical problems, such as grinding angle, grindstone grain thickness, but will not get a knife is worn out, so if there is no point, or don't use.

- Q:If there is no counter near the mill, you can grind it?

- Zwilling has a knife in the knife, you can grind, but there is a direction, you can ask. If there is no sharpener, don't you, that's your knife will gaohuai.

- Q:Sharpening stone and sharpening rod which make

- You have to look at what to do with the edges of open front should use the grindstone three steps in the most thick about 200 mesh or a blade and then use about 500 of the burr and then polishing about one thousand meshes are generally not edged from ordinary knife before two step is enough if you are collecting or play knife appearance and extreme sharpness can add third step if the sharpness of the knife is hard to add a step with ruby grindstone (3000 mesh) and agate grindstone (8000 to 10000).If your knife is paused or just ordinary kitchen knife sharpener with rust. It can only be used for ordinary knife usually use tableware like playing with a knife sharpener, sharpener tube are called destroy knife can only be a few weeks with a knife grinding rust

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Ti-coated Diamond Stone for Professional Knife Sharpening

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 20000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords