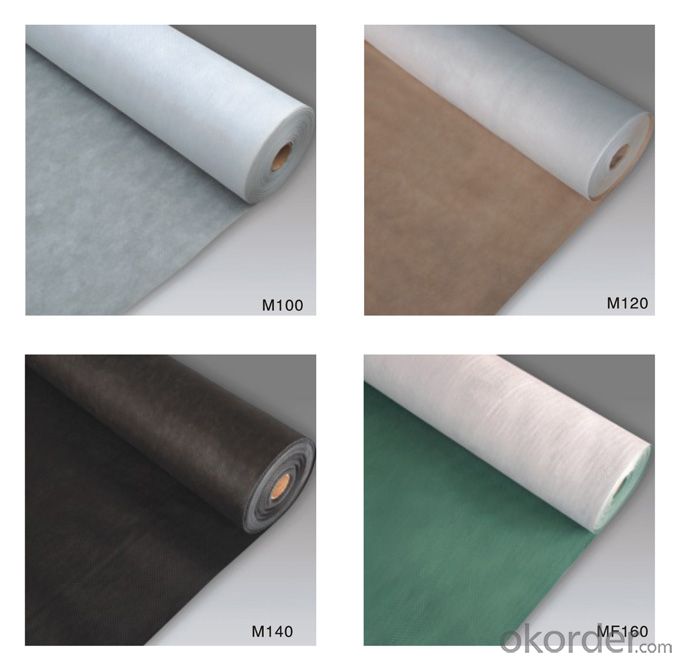

Three Layer Breathable Membrane

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Three Layer Breathable Membrane

Breathable membrane is thermal laminated by the high polymer material in the middle layer . Paving on the top of the insulation system, it can strengthen the water tightness of the building, as well as to eliminate humidity inside the containment by the unique breath ability, thus to retain the duration of building effectively , playing a part in thermal insulation, energy conservation and living environmental improvement.

We pay high attention to the quality of products, advance production equipments, perfect detection means, sound ISO system, powerful ability on technical research and management formed the preeminent “ Shanquan” quality.

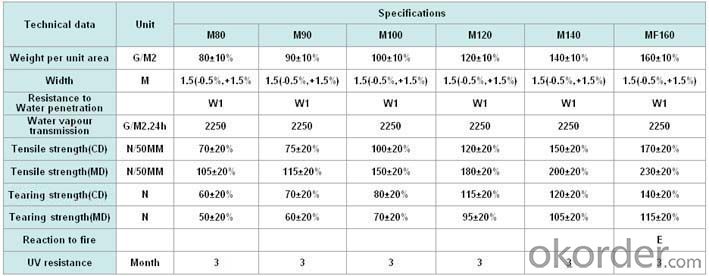

EN13859-1

- Q:Villa roof leakage what general reasons, what materials to remedy

- Fourth, the roof of a large area of ??leakage or a number of water leakage points, the first by the professionals to check whether the cracks, according to the previous program to deal with the cracks in the roof covered with waterproof membrane, to enhance the waterproof effect, but also And then covered with insulation board, because the height of the insulation board in 20 cm or more, to achieve the protection of waterproof layer and thermal insulation of the double effect. Wall cracks appear seepage, under normal circumstances the professional construction team will use the basket, by the maintenance staff in the external wall construction.

- Q:How can the toilet waterproof works fail?

- Can only do a new waterproof, and now have engaged in the base of the waterproof coating, the effect is very good. It is best to ask professionals to do their own difficult.

- Q:Can Henkel have water against him?

- Can ah ~ watered effect on the discount friends are high with the general are good, powder + pulp! Do not need to add water

- Q:Nanning building waterproof material market where

- This depends on what you need packaging materials, and if it is some packaging rope or paper or process raw materials and other different materials to find a different place, generally sold outside the packaging is more like Nanning near the train station Or the trading market,

- Q:What is PE waterproof cloth and PVC tarpaulin

- Waterproof cloth product features and the use of attention 1. Has a waterproof, mildew function, and a light material, high tensile strength, Naisuan Jian, high temperature, easy to wash and so fold the characteristics of folding; 2. This product should be used in the process should avoid sharp impact with the sharp metal; 3. If the product is damaged, can be used to repair glue.

- Q:Oriental rain rain waterproof how to

- Oriental rain rain waterproof paint is not good to say it, but real to do it, rely on the quality of their own business for the relentless pursuit and practice. Oriental rain rain waterproof coating from the selection to the production to the final product testing are as much as possible meticulous.

- Q:Hello, roof with SBS waterproof material bulk density is how much?

- Similar to styrene-butadiene rubber, SBS can be in contact with water, weak acid, alkali, etc., with excellent tensile strength, surface friction coefficient, low temperature performance, excellent electrical properties, good processing properties, as the current consumption of the largest thermoplastic Elastomer.

- Q:Home improvement waterproofing problem

- 2, the ground waterproof layer generally turned 20 cm. Use the shower parts generally do more than 2.2 meters.

- Q:How does the waterproofing membrane work?

- 4, rolling the membrane: the first turn up the end of 1m long, with a long torch melting the bottom of the hot melt adhesive, the rapid paste fixed on the grassroots, and then re-harvest the rest of the volume. The gunmen stood on the paved webs, aligned with the corners of the rolls and the surface of the base layer with the flame of the long gun, and slowly rolled the edges by melting the hot melt. The web is pasted on the base;

- Q:How to do waterproof bathroom, construction process is what

- First, the bathroom waterproof method: 1, brush the first time waterproof coating. Before the construction to ensure that the ground dry, waterproof coating to be painted, no omission, and the combination of solid grass, no cracks, no bubbles, no shedding phenomenon. Brushing the same height, the thickness of the product requirements to meet the requirements.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Three Layer Breathable Membrane

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Hot Searches

Related keywords