Three And Five Layers Co-Extrusion Film Blowing Machine Set (IBC), Extruder, Blowing Machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 15 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | nude packing or wooden case packing as your request |

| Delivery Detail: | 30 days after receipt 30%T/T as deposite |

Three to five layers co-extrusion film blowing machine set (IBC), extruder, blowing machine

This machine set is to satisfy the customer’s requirements of high quality, high output film blowing equipment.

It adopts the extruder with force feeding function, precision type ceramic heater, precision type double vents air ring, horizontal type rotary traction system, fully automatic surface friction type double cut double winders, computer concentrate control system.

Advanced technique and equipments, compare with kindred equipment, it has the advantages such as more compact structure, high output, better produce quality, less energy consume, easier operation.

It can be widely used into various kind of high transparence packing film manufacture and create the considerable economic benefit for you.

Fully automatic double cut double winders

Optional parts:

Auto loaderX3pcs

Chiller

Corona

Full automatic winder

Embossing roller

collecting material drop

Technical data:

Model | MD-3L50 | MD-3L55 | MD-3L65 |

Suitable Material | LDPE LLDPE EVA HDPE | ||

Max Film Width(mm) | 1200 | 1500 | 2000 |

Film Thickness(mm) | LD:0.015-0.15 | ||

Max Extrusion Output LD | 140kg/hr | 200kg/hr | 280kg/hr |

Extrusion unit | |||

Gear Box | 146/173/146 | 173/200/173 | 200×3 |

Screw Diameter(mm) | φ50/55/50 | φ55/65/55 | φ65/65/65 |

Screw L/D Ratio | 28:1 | ||

Screw’s Material | 38 CRMOALA | ||

Barrel’s Material | 38 CRMOALA | ||

Barrel’s Cooling Fan | 370W×2×3 | 370W×2×3 | 370×3×3 |

Thermo Control (zone) | 3×3 | 3×3 | 4×3 |

Driving Motor (kw) | 15/22/15 | 22/30/22 | 30/30/30 |

Extrusion Die | |||

Die Size (mm) | LD:φ250/300 | LD:φ350/400 | LD:φ500 |

Rotary Die Head (mm) | 360°Continue Rotary | ||

Screen Changer | Manual Mechanics Screen Changer | ||

Thermo Control (zone) | 3 | 4 | 4 |

Air Ring | 1 PCS | ||

Cooling Blower (kw) | 5.5 | 7.5 | 11 |

Take-UP Unit | |||

Roller Width (mm) | φ165×1300 | φ165×1600 | φ190×2100 |

Take-UP Motor (kw) | 1.5 | 1.5 | 2.2 |

Take-UP Speed(M/min) | 5-60 | 5-60 | 5-60 |

Winding Unit | |||

Type OF Winder | Surface Friction Double Winder | ||

Roller Width (mm) | 1300 | 1600 | 2100 |

Winding Motor | 16N.M | 1.5kw | 1.5kw |

Winding Speed(M/min) | 5-60 | 5-60 | 5-60 |

Voltage | 380V, 50HZ, 3PHASE | ||

Cover Dimensions (m) | 6.8×2.6×6.5 | 7.5×3.2×7.5 | 9×4.2×9 |

Three to five layers co-extrusion film blowing machine set (IBC), extruder, blowing machine

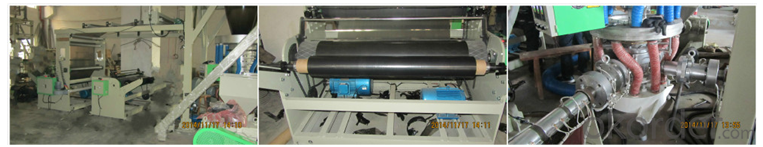

Machine at factory,double winder,simple type

Our other hot-sale machine(click the picture to know more information)

Company show

- Q:What are the types of oil filters? Oil filter?

- Oil filter is widely used, as long as it is not dry oil equipment, oil can be used to filter oil processing, and now 90% of the country is still in the third generation of products, can produce fourth generations of manufacturers rarely. Have questions can contact me, please wait a minute.

- Q:Vacuum oil filter price vacuum filter oil quotation vacuum filter oil machine how much?

- [1] general import oil filter is generally about the price of domestic oil filter of the times, good quality, long service life, small problems are less, but the purchase service more trouble, the late filter must also be imported, high cost, generally only high-end projects and high-end users will use. [2] domestic oil filter machine generally can be divided into three: the first is the high-end oil filter, in the domestic price is higher, but the quality is good, service and thoughtful customer service. Such manufacturers generally pay more attention to long-term development, basically in the forefront of the industry, the scale is also large. The second is the domestic mid-range oil filter, the overall quality can also, customer service service also can basically guarantee, is sometimes some small parts easily damaged, such as temperature controller, floating ball, valve, pipe and so on, the price a little cheaper than the first. The third is the domestic oil filter machine in the low-end goods, like all other low-end goods and services cheaper goods, not the bottom line, can not guarantee the quality of service, customer service can not talk, can do a single a single, oil filter small problems very much, seriously delay the user production.

- Q:What is the return of the oil filter?

- That estimate the filter has a problem, filter oil machine is not set up, or filter plug. Or the connection is wrong

- Q:What is the effect of the oil filter on the filtration of fine particles?

- When the temperature occurs, the reactions will not react with the filtered liquid and will pollute the filtered liquid. As long as it is not the core technology of the company, the problem of oil treatment and filtration can be exchanged.

- Q:The oil filtered by a vacuum oil filter is then placed in a centrifugal oil filter and filtered without salt water

- You must add water without adding salt water, which is to remove the residue

- Q:What is the influence of the vacuum degree of vacuum oil filter?

- Vacuum oil filter machine is based on oil and water there is a big difference in boiling point, boiling water in a high vacuum state is greatly reduced (because the oil can not be run at high temperature can only be a vacuum state so that a large number of water evaporation and oil can remain liquid, so the choice of the vacuum state to oil-water separation), without considering the altitude. The general temperature at 65 degrees, vacuum 0.06MPA, oil-water separation effect is the best.

- Q:Why is there a load switch, no oil filter?

- On load switch has oil filter, oh, there is a very small flow capacity DZX switch on line filter

- Q:What are the considerations for selecting an oil filter?I am the company procurement, workshop to buy oil filters, selected a lot of homes, almost all, a little bit Mongolia, specifically what should pay attention to ah?

- 2. Know the total amount of oil to be filtered, and select the appropriate oil filter (how many liters per minute)3, mobile or fixedWhere are you from?

- Q:What is the principle of vacuum oil filters used in steam turbines?

- PX is the use of physical means, without affecting the moisture, impurity and gas contains a large number of rapid removal of oil oil components and the premise of the performance of the liquid (acetylene, hydrogen, methane and other harmful ingredients; etc.) can have on steam, Water Leakage, aging, acid, foam, emulsified oil product purification. The quality indexes of the oil products meet the requirements of the quality standard of turbine oil in operation of GB/T 7596-2008

- Q:Portable continuous refining machines and pneumatic oil filters that good

- First of all: you hit the wrong character, no portable oil refining machine, oil machine is also true of petrochemical enterprises will have less, while more than hundreds of thousands, millions, and refining facilities generally large, covers a wide area, how likely is portable, so you should be a portable oil filtering machine.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Three And Five Layers Co-Extrusion Film Blowing Machine Set (IBC), Extruder, Blowing Machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 15 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords