Three And Five Layers Co-Extrusion Film Blowing Machine /Plastic Film Blowing Machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 15 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | nude packing or wooden case packing as your request |

| Delivery Detail: | 30 days after receipt 30%T/T as deposite |

Three to five layers co-extrusion film blowing machine set (IBC), extruder, blowing machine

This machine set is to satisfy the customer’s requirements of high quality, high output film blowing equipment.

It adopts the extruder with force feeding function, precision type ceramic heater, precision type double vents air ring, horizontal type rotary traction system, fully automatic surface friction type double cut double winders, computer concentrate control system.

Advanced technique and equipments, compare with kindred equipment, it has the advantages such as more compact structure, high output, better produce quality, less energy consume, easier operation.

It can be widely used into various kind of high transparence packing film manufacture and create the considerable economic benefit for you.

Fully automatic double cut double winders

Optional parts:

Auto loaderX3pcs

Chiller

Corona

Full automatic winder

Embossing roller

collecting material drop

Technical data:

Model | MD-3L50 | MD-3L55 | MD-3L65 |

Suitable Material | LDPE LLDPE EVA HDPE | ||

Max Film Width(mm) | 1200 | 1500 | 2000 |

Film Thickness(mm) | LD:0.015-0.15 | ||

Max Extrusion Output LD | 140kg/hr | 200kg/hr | 280kg/hr |

Extrusion unit | |||

Gear Box | 146/173/146 | 173/200/173 | 200×3 |

Screw Diameter(mm) | φ50/55/50 | φ55/65/55 | φ65/65/65 |

Screw L/D Ratio | 28:1 | ||

Screw’s Material | 38 CRMOALA | ||

Barrel’s Material | 38 CRMOALA | ||

Barrel’s Cooling Fan | 370W×2×3 | 370W×2×3 | 370×3×3 |

Thermo Control (zone) | 3×3 | 3×3 | 4×3 |

Driving Motor (kw) | 15/22/15 | 22/30/22 | 30/30/30 |

Extrusion Die | |||

Die Size (mm) | LD:φ250/300 | LD:φ350/400 | LD:φ500 |

Rotary Die Head (mm) | 360°Continue Rotary | ||

Screen Changer | Manual Mechanics Screen Changer | ||

Thermo Control (zone) | 3 | 4 | 4 |

Air Ring | 1 PCS | ||

Cooling Blower (kw) | 5.5 | 7.5 | 11 |

Take-UP Unit | |||

Roller Width (mm) | φ165×1300 | φ165×1600 | φ190×2100 |

Take-UP Motor (kw) | 1.5 | 1.5 | 2.2 |

Take-UP Speed(M/min) | 5-60 | 5-60 | 5-60 |

Winding Unit | |||

Type OF Winder | Surface Friction Double Winder | ||

Roller Width (mm) | 1300 | 1600 | 2100 |

Winding Motor | 16N.M | 1.5kw | 1.5kw |

Winding Speed(M/min) | 5-60 | 5-60 | 5-60 |

Voltage | 380V, 50HZ, 3PHASE | ||

Cover Dimensions (m) | 6.8×2.6×6.5 | 7.5×3.2×7.5 | 9×4.2×9 |

Three to five layers co-extrusion film blowing machine set (IBC), extruder, blowing machine

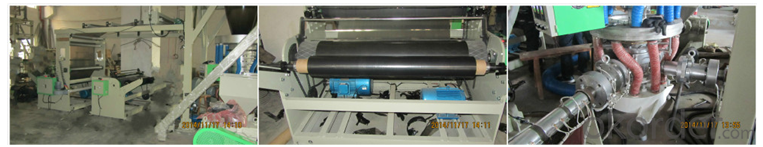

Machine at factory,double winder,simple type

Our other hot-sale machine(click the picture to know more information)

Company show

- Q:Which is more practical, plate pressure type oil filter and multi-function oil purifier? What are their advantages and disadvantages?

- Characteristic:1, super demulsification dehydration and degassing system, with large volume, enhanced three-dimensional flash tower and thin film evaporation technology and a large area of multi-level oil water gas separation technology, can fast remove the oil in the water, gas and light hydrocarbon.2, the use of high quality filter original and sealing materials, corrosion resistance, high temperature resistance, good mechanical strength, to meet the high viscosity of the filter oil needs higher temperature requirements, expanding the range of its purification of oil.3 、 precise multi-stage filtration system can effectively remove mechanical impurities in oil.4 、 advanced pressure protection device, liquid level control system, to avoid the misoperation of the equipment.5 、 perfect automatic and manual electric heating temperature control device, automatic separation cooling device, simple operation, safe and reliable.6, the machine can also be used to meter and timers, users can carry out automatic measurement of fuel quantity and working time.

- Q:How much is the 90 screw frying machine?

- Oil press related configuration, such as speculation machine, oil filter, peanut sheller, conveyor and so on the specific configuration.The difference between the new and the old, the old models of oil press consumption of TV, slow, relatively cheap price.

- Q:The vane filter and the centrifugal oil filter are good

- Choose which specific, you need to see what materials you deal with, what you want to achieve

- Q:Main parameters of ZYA-50 vacuum oil filter

- Characteristic:1 、 double stage high vacuum pumping speed, can quickly and efficiently remove water vapor in the oil, so that oil drying degree, breakdown voltage value and one-time filtration effect are greatly improved, shortening the oil treatment period.2, advanced dehydration and degassing system, using a large area of flash evaporation technology, can quickly remove moisture in the oil, gas and volatile classification of harmful ingredients.3 、 precision filtration system, multi-stage filtration, step by step encryption, can effectively remove mechanical impurities in the oil; high quality filter, corrosion resistance, mechanical strength, durable.4 、 sensitive automatic pressure protection device and infrared liquid level control system, feeding and heating linkage system, forming the whole chain safety protection system, simple operation, safe and reliable.5 、 vacuum suction and vacuum oiling function for power equipment. Used to treat other types of low viscosity lubricating oils. Compared with single stage vacuum oil filters, it can improve work efficiency by more than three times.

- Q:Under what conditions does the air pressure oil filter fail to clean oil?

- Oil is too dirty or used in an unsuitable oil filter. There will be filters that are not clean

- Q:How to assemble and disassemble the vacuum pump for power generation oil filter?

- You'd better consult someone who sold you the oil filter, so they would have to come in and install it during the warranty period

- Q:Points for attention of vacuum oil filter

- 1.4 check whether the external power supply is correct, whether the power cable meets the capacity requirements of the oil filter.1.5 check the machine housing should be reliable grounding.1.6 check that all rotating parts should be free of obstruction.1.7 test turn, check the oil pump, vacuum pump and other motor steering should meet the requirements.1.8 check whether the cooling water connection is reliable and the water should be clear.1.9 check field fire extinguishers to meet the requirements.

- Q:How much is the equipment for the oil press?

- Oil press complete sets of equipment, in general, the price of 20 thousand yuan -3 yuan.In general, the oil mill complete equipment configuration includes: fried material machine, oil press, oil filter.In addition, the workload is different, processing materials are different, hot and cold pressing method is different, the corresponding configuration is also different.

- Q:How often is the filter element of the transformer oil vacuum oil filter changed?

- Usually a good filter can be cleaned and reused later until it is broken. Some are changed only once a year, and some half a year, according to the oil,

- Q:How can I get rid of the cooking oil and the sediment filtered out by centrifugal oil filters?.

- An oil filter is a filter device for removing mechanical impurities, byproducts and moisture in impure oil by gravity, centrifugal, pressure, vacuum distillation, mass transfer and other techniques. Oil filter is mainly used to improve the cleanliness of machinery and electrical oil, so as to give full play to the best performance and extend the service life of equipment.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Three And Five Layers Co-Extrusion Film Blowing Machine /Plastic Film Blowing Machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 15 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords