Thickness 6mm Ceramic Fiber Blanket for Cement Kiln Made In China

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 100000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Thickness 6mm Ceramic Fiber Blanket for Cement Kiln Made In China

Ceramic Fibre Blanket Discription

Ceramic fiber product is made from high quality Gao-ling clay, high purity alumina and silica oxides by spun or blown process. It is asbestos free. No chemical binder is added. Double-side needling provides blanket with great tensile or handing strength for easy installation.

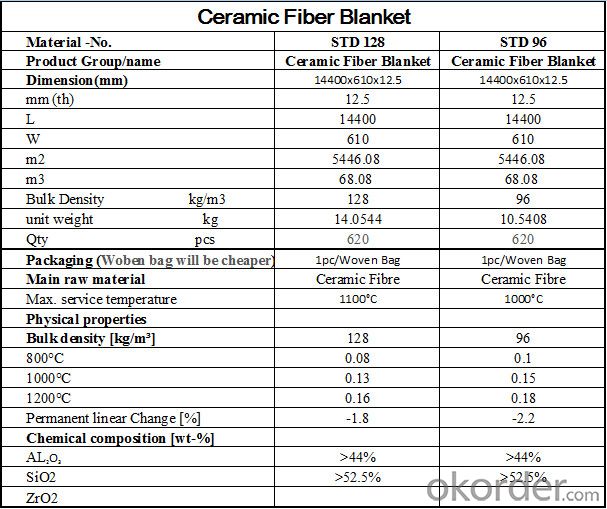

There are four kinds of ceramic fiber products according to the temperature and chemical content. They are STD(1260℃),HP(1260℃),HA(1350℃, high alumina),HZ(1430℃,contain ZrO2).

1) For the blanket, the bulk density will be 64kg/m3, 96 kg/m3, 128 kg/m3, 160 kg/m3.

2) For the paper, the bulk density will be 160-220 kg/m3.

3) For the board, the bulk density will be 240-400kg/m3.

Ceramic fiber blanket, board,cloth and textiles are made from high quality clay, high purity alumina and silica oxides by spun or blown process.

Ceramic fibre blanket, board and cloth have a range of products:ordinary type,standard form,high-purity type, high-alumina type and containing zirconium type.Different types of products used different materials. performance of ceramic fibre insulation blanket also has difference,and they are suitable for different workong temperatures.

Ceramic fibre blanket, board and cloth can be used after optional cutting .When ceramic fibre insulation blanket storage should be paid attention to moistureproof.The high-alumina type and containing zirconium type products can be directly used as furnace lining .And using high-temperature refractory adhesive when stick.

Packaging & Delivery

Each Roll/Case:12.5*610*14400mm, 25*610*7200mm, 50*610*3600mm

Characteristics of Ceramic Fibre Blanket

1)Low thermal conductivity

2)High tensile strength

3)Resilient to thermal shock

4)Corrosion resistance

5)High-purity type

6)High-temperature refractory

7)Al Content (%): 32-55

8)Type: 1260℃ STD/HP, 1350℃ HA, 1430℃ HZ

9)Density: 64-160kg/m3

10)Size: 12.5×610×14400mm, 25×610×7200mm, 50×610×3600mm

Applications of Ceramic Fibre Blanket

1.Industrial furnace, heating devices, high temperature pipe

2.High building fireproof ,sound-absorbing and thermal insulation material

3.Thermal insulation material for the electricity boilers, gas turbine and nuclear power.

4.Wall linings of the chemical high-temperature reaction equipment and heating equipment.

5.Thermal insulation for the furnace door and roof.

Images

Technical data of Ceramic Fibre Blanket

FAQ

We have organized several common questions for our clients,may help you sincerely:

How about our ceramic fiber products?

A world class manufacturer & supplier of ceramic fiber product is one

of the large scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 80000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q:I know, I know, straightening your hair can cause future damage, but that is the main reason I am asking this questionI was wondering, is there some kind of hair cream or straightener that will help make it so you won't get frizzy hair or split ends? Or should I just perm it, even though doing so the chemicals could damage it even more? My hair looks horrible if it is not straightened and the start of a new school year is coming up and I would love to have a good first impression on peoplePlease and thank you!

- Harvey, you should have saved up a little more and sprung for the 64 count of crayons.it comes with a built-in crayon sharpenerIt'll help you seem slightly more knowledgeable about these topicsIn light of that oversight, let me put it in terms even you might understand: What sounds better to you? 1) Bang, bang, bang, bang, bang, pingor 2) Bang, bang, bang, bang, bang, bang, bang, bang, bang, bang, bang, bang, bang, bang, bang, bang, bang, bang, bang, bang, bang, bang, bang, bang, bang, bang, bang, bang, bang, bangReload and repeatPersonally, I prefer my freedom belt-fed, but a 30 round magazine comes in at a close secondWhat say you? EDIT: Since you're clearly affected on an emotional level, I hesitate to even attempt to help you understandIt is obvious you've never servedWhen you have to hump 200 rounds of ammo, 5.56 suddenly seems like a winnerStill not convinced? How about putting it in terms of effective fire (i.erounds on target)? Ever seen suppression from an M249? Easier to maneuver, transport, supply, and fireThe efficacy of a cartridge goes well beyond ftlbsof energy delivered on targetConcerned about reliability? The modern AR-15 is vastly improved when compared to the original M16, so to take Viet Nam era complaints as reason for dismissing a rifle's value is absurd.

- Q:We put blankets on horses in the winter, why not beef and dairy cattle? Don't they get cold too?

- Actual scientific research - if you give cattle a choice of many different temperature areas they will end up staying in the one that about 55 degrees FWinter temps do not feel as cold to them as to the temperate 70 degree loving humansPlus if they are housed in an open area by winter they will grow lots o hair (like 3 inches - honest) Now horses would grow similar hair and be just as warm outside but we humans think the shaggy coats look unkempt and its harder to cool the shaggy horse down after a ride so we clip them or keep them always blanketed to keep them from getting shaggy.

- Q:I lift weights and jog and take martial artsI need to know what can drink or take that helps me with building lean muscle and recovery from workoutsPlease tell me something that does not cause acne and stuff like thatThanks.

- This Site Might Help YouRE: Can you quot;over insulatequot; your attic? With all the talk about going green and energy efficient, can you add too much insulation to your attic? What kinds of problems can you have if you add too much insulation?

- Q:My sister said that her class used to have a gerbil class petShe said that is had a little blanket that it carried around with it and snuggled withDo you think my gerbil would do fine with this if it was a small piece of cloth?

- While it is a cute concept, you should NEVER give gerbils any kind of clothSince they chew and shred everything in their path, they will begin to shred the cloth and the long fibers could choke them or get caught up around a leg or tail and cause serious injuryIt is fine to give your gerbils unscented toilet paper though- and they love itThey may carry that around for a bit but then will end up shredding it and using it to help make their nest nice and soft.

- Q:Do i need an Under The Tank Heater, an Over The Tank Heater, or both?? And how do i create a basking spot? Thanks :) PSI don't have the snake yet, so don't worry.

- This Site Might Help YouRE: What is a circuit breaker how does it work ?

- Q:I been having runny noses, sneezing, itchy throat for a the past couple of dayspeople are saying i might have a fever and i think its just allergieswhat is the difference between them?

- CHICKEN ON THE RANCH Number of servings: 2 to 4 INGREDIENTS 1 tbs butter 2 to 4 chicken breast halves or thighs( thawed) 1/3 cup onions 1/3 cup of Ranch dressing or 2 level tsps, dry Ranch salad dressing 2 cups rice 4 cups hot water INSTRUCTIONS In a large frying pan, sauté onions until just tender Add rice and heat until rice starts to lightenAdd hot water, Ranch dressing and stir until blendedBring to a simmer and place chicken on topCover and let simmer for 20 to 25 minutesTurn off the heat, lift lid and place a paper towel over the top, then replace the lidLet stand for 5 minutes more.

- Q:Hello,I just finished putting insulation and walls in my unfinished, unattached garageNow to help keep the heat in and make it look better, I want to put a ceiling and some R19 upMy question is, what building material would be best for the ceiling and also, can I even do this because its made of 2x6's running a 15' span at 48quot; on centerI know I would have to add wood to keep anything I put up from sagging, but will the construction be strong enough to hold all of that up and some storage also?Thanks in advance!

- Personally, I load my ownWhile it is cheaper per bullet, the price doesn't take into account the cost of my timeI don't much care, because I enjoy it, but you might feel differentlyThe cheapest commercially, commonly available ammo that I've found is CCI BlazerYou mention that your range doesn't allow it, and that may be because the cases for the cheapest Blazer ammo are not brassHowever, CCI also makes a cartridge with a brass case called, appropriately, Blazer BrassIt's a brass case with a jacketed lead bullet, so I can't think of any reason that a range would prohibit its use, except that they make money when you have to buy your ammo from themBlazer Brass is available from Wal-Mart for about $11 or $12 per box of 50.

- Q:I hate my sheetsI always feel hot and they aren't very soft and they are kinda thickIt gets really hot in the summer and I want some sheets that will keep me coolMy friend told me it had something to do with the thread countCan you please explain what the thread count is and what the good kinds are? What kind of sheet should I use?

- There are actually twoIn a split unit ( the one where a big box thing sits outside and there's a central furnace inside) there is the evaporating coil on the inside of the house and the condensing coil on the outside.

- Q:So my IBS attack went on for four days straight! Today is much better, much less gas and little crampingI have not eaten since last night, and its not almost noonI am just afraid to eat anything because I do not want to spark the attack again I literally cannot eat anything without getting an attack anymore The last two days have been the worst that iv'e ever had to the point where i did not want to leave my house I need some help on things I can eat, so i am not hungry and things that are safeI am honestly so tramatized after these four days that I really need friggen help What are the safe foods? Pleasee help, this is ruining my life!

- I take: 1 cup brown rice 2 cups chicken broth 1 tablespoon butter 1/4 teaspoon of salt bring to a boil and turn heat down to a simmer for 45 - 50 minutesCook with a lid on it I do check it a few times to see if it need more moisture and will add an 1/8 cup of water if neededYour rice should never be hard or mushy if you can keep an eye on itIt is often said to never lift the lid while cooking rice but I never am able to make it perfect w/o checking on it Note that brown rice is a wet rice dishIt comes out creamy and wetNot fluffy like some white rices Good luck!

- Q:I’m 5’2, female and 45kg.I’m trying to lose weight but every time I exercise I gain weight? I went from 41kgs to 45kgs in a matter of about two weeksI’ve been exercising nearly every day for an hourI’ve been eating healthy plus I always drink water and my thighs seem to increase in size more and more everydayDoes anyone know how I could lose it instead of gaining it?

- trust me i believe u psychopath

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Thickness 6mm Ceramic Fiber Blanket for Cement Kiln Made In China

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 100000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products