Thermal Insulation Fiber Glass For Building Roofing and Wall20KG/M3

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 400 roll

- Supply Capability:

- 10000000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Glass Wool are widely used in public, commercial and residential buildings as well as industrial plants, for applications such as roofing, external wall, partition wall and floating floor to provide fire protection, thermal insulation, acoustic control and condensation control.

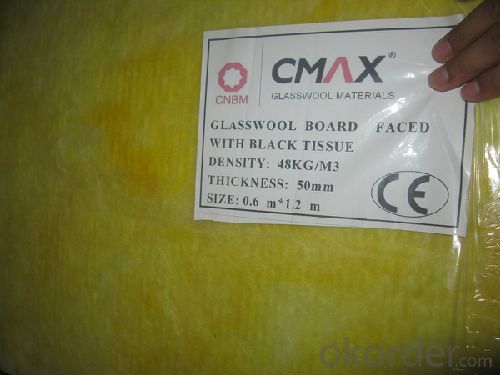

Item | Unit | Index |

Density | Kg/m3 | 10 - 48 |

Thickness | mm | 25-150 |

Width | mm | 1200 |

Length | mm | 5000-30000 |

● FEATURES

● Thermal Insulation ● Fire Safety ● Acoustic Control

● No Corrosion ● Environmental friendly ● Moisture Resistance

● Energy Conservation & Emissions Reduction

Standard Size

Blanket

Size: W*L (mm) 1200X10000 ( 10000- 30000)

Thickness (mm) 25, 30, 50, 60, 80,100

Technical Data

Item | Unit | Index |

Average Fiber Diameter | μm | About 7 |

Water Content | % | ≤1 |

Grade of Combustibility | Non-Combustible Grade A | |

Thermal Conductivity ( 25℃) | W/mK | 0.038- 0.045 |

Reshrinking Temp | ℃ | ≥300 |

Hydrophobic | % | ≥98 |

Moisture Rate | % | ≤5 |

Noise Resistant Coefficient (NRC) | About 0.75 | |

Slag Inclusion Content | % | ≤0.3 |

Material:

Double layers of aluminum foil reinforced with high tensile spring steel wire

Structure: High elastic wire, aluminum foil. A reinforcement model can be required.

Aluminum foil thickness: 0.035mm

Temperature range: -30°C~+140°C

Maxim Air Flow: 30m/s

- Q:If rock wool board and glass wool are used in enclosed stone curtain walls, which one is better?

- 1. Glass wool has a lower thermal conductivity than rock wool, and glass wool keeps about about 650 in melting crunode; firewall behind the glass curtain wall mainly use rock wool with a volume-weight of 60 to 64, and its melting crunode is about 1200.

- Q:what's the temperature the high temperature glass wool endure?

- The maximum temperature is 300 degrees.

- Q:Does anyone know about the filling materials in the steel stud, is it glass wool or mineral wool?

- Generally, rock wool is the filling materials.

- Q:what's the differences between glass wool roll mat and rock wool roll mat? does glass wool roll mat have any mandatory retest requirements or environmental requirements?

- Steel structure roof basically uses glass wool roll mat, because rock wool roll mat is six to ten times heavier than glass wool roll mat, light steel frame can't bear so much gravity, glass wool is more fluffy than rock wool, so it's thermal insulation effect is better, glass wool is cheaper than rock wool, the glass wool fire rating is A-level flame retardant, now people won't use the rock wool blanket, wall thermal insulation used rock wool board.

- Q:What kind of glass wool is used for most buildings?

- Ask the dealer for product descriptions, and you can search its specifications and parameters and then design based on the performance specifications of specific products. I suggest you first determine which brand of thermal insulation cotton to use, or check if the number is in the tolerance range of national standards of the manufacturers, of course, it is a relatively wide range. I recommend Owens Corning ultrafine glass fiber insulation cotton.

- Q:Can Kunnai glass wool board and sound absorption blankets be used to maintain sound insulation in hotel floor? Can it decrease half of the noise? How to install?

- Pour concrete with the thickness of 4-6 cm to the shock absorption pad. The floor treatment is mainly for solid conduction, and the surroundings also need to be isolated by shock pad. Shock absorption pad and concrete floor can ensure that the newly-poured floor is not hard-wired with the original building.

- Q:What performance characteristics does aluminium foil ultra-fine glass wool board have?

- 1, It has characteristics of waterproof ability, corrosion resistance, no mildew and no insect, able to prevent condensation effectively and prevent pipes from freezing. 2, It is light in weight, high in sound absorption coefficient, low in thermal conductivity with noninflammability and fire-retardant capability as well as chemical stability. 3, It is low in cost, good in hydrophobic property, good in elasticity and softness, which enables it to be a both commonly used insulation material and commonly used cold retaining material. It has a wide range of applications with stable product performance.

- Q:Why does glass wool turn black when exposed to heat? Wether it will ffect the thermal insulation effect.

- The burning like alcohol lamp uses glass wool as the substrate. There are two possibilities to take alcohol lamp to do experiment, which containing organic substances. 2. 1, High temperature oxidation. I produce aerogel thermal insulation felt, and I have seen that the charcoal ash produced is attached to the glass wool. It has some impact on thermal insulation effect, but the impact is small.

- Q:The differences between rock wool board and glass?wool?board

- good explanation

- Q:is glass wool fireproof?

- A class fireproofing and hydrophobic.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Thermal Insulation Fiber Glass For Building Roofing and Wall20KG/M3

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 400 roll

- Supply Capability:

- 10000000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products