Thermal Extruded Polystyrene board/XPS insulation foam panel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

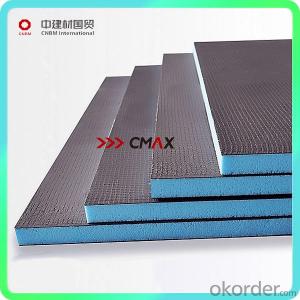

| Type: | XPS Boards,Heat Insulation Materials | Place of Origin: | Brand Name: | ||

| Model Number: | WL-XPS | Thickness: | 20-50mm | color: | Blue, Pink,Green, Grey etc. |

| Density: | 32-35kg/m3 | Width: | 600-1200mm | Length: | 1200-10000mm |

| Compressive Strength: | 280-400kpa | Surface: | Smooth and Rough |

Packaging & Delivery

| Packaging Detail: | plastic packaging or according to client's request |

| Delivery Detail: | 10-15days |

Specifications

Thermal extruded polystyrene board/XPS insulation foam panel

1.Great anti-corrosion

2.Water-resistance

3.Fire prevention

Thermal extruded polystyrene board/XPS insulation foam panel

² Description:

1. XPS is an extruded polystyrene insulation manufactured through a plastic extrusion process. The

resulting boards are almost 100% closed cell, strong, highly moisture resistant and easy to cut and shape.

2. XPS is particularly indicated for places where a high mechanic resistance is required. Its resistance

to water and compression make it the ideal insulation solution for extreme conditions. Moreover, it is

very easy to install and offers a high performance thermal insulation for your building.

3. XPS foam board widely used in wall insulation, low-temperature storage facilities, parking platform, the airport runway,construction of concrete roof and the structure of roof, highways and other areas of misture-proof inexpensive decoration industry material.

Thermal extruded polystyrene board/XPS insulation foam panel

Length(mm) | Width(mm) | Thickness(mm) | Density(kg/m3) |

1200-10000 | 600-1200 | 20-50 | 32-35 |

Compressive Strength(kpa) | color | Surface | |

280-400 | Blue,Pink,Green,Grey etc. | Smooth and Rough | |

- Q:How is the flame and combustible defined by the naked eye? I burn the B1 level and B2 level XPS board is different? Question added: detection time is longer, can quickly and intuitively identified? More

- Air-conditioned room can not have flammable gas, in order to avoid explosion and fire do not frequent switch air conditioner, because the compressor starts when the current is running a lot of times the current, easy to burn the compressor motor 3) Do not put things on the outdoor unit of the air conditioner to avoid air conditioning noise. It is a great persecution for the air conditioner. The temperature of the general air conditioner is adjusted to 26 ° C to 28 ° C. , To avoid excessive power consumption next to the air conditioner must not be twitching Fengqi gong bite astringent ax to have a high temperature heat source, so as not to heat the panel deformation

- Q:What is the difference between an extruded board and an XPS extruded board?

- What is the form of this, and you want to be on the scene to be helmet helmet helmet gnome insects rhinoceros kitery to be set. But single, double row scaffolding with a high degree of single-row scaffolding should not exceed 24M, double row scaffolding erection height can not exceed 50 meters, more than 50 meters high double scaffolding should be double pipe, sub-unloading, sub-erection and other measures The "Technical Specification for Safety of Fastener Steel Scaffolding" JGJ130-2011

- Q:How to distinguish between good and bad insulation board insulation board

- Your main source of high temperature in the room is the west of the glass and the south of the window you can in the west and south from the glass 20_50 cm hanging curtains so much of the heat was blocked the roof available 60 * 60 gypsum board ceiling that Economic effect and good ceiling 15-18 yuan per square

- Q:Roof insulation layer is extruded polystyrene foam plate how set the amount of set

- Use the wall connection, set the location, the number of construction sites in accordance with the development of specific programs to determine. But also must meet the "construction of fastener type steel pipe scaffolding safety technical specifications JGJ130-20 lack of reminders of the United States and the United States and the United States and the United States and the United States and the United States, Note: . different erection mode, different height, the vertical spacing, horizontal spacing, each wall with a specific coverage area requirements. . pay attention to the standard is JGJ130-. do not use JGJ130-2002 old standard, the old and new standards on the wall with a little different provisions.

- Q:Steel plant wall plug color steel tile, the glass glass inside the glass, hanging in color steel, how construction? How is the cost associated with a single sandwich panel?

- More than 24 meters need to use cantilevered scaffolding, and the spacing of not more than 20 meters

- Q:I set up in October 2008, the production of XPS board - that is, with the extinction of polystyrene foam plastic plate, is an energy-saving environmental protection materials. Consult experts: I can enjoy the relevant tax incentives?

- 25 thick extruded polystyrene plastic insulation board 35kg / m3

- Q:Extruded Polystyrene Board, Polystyrene Foam Board and Expanded Polystyrene Board

- Market price, no quota. According to the different brands, the price is different! I hope useful to you!

- Q:25 thick extruded polystyrene plastic insulation board how many kilograms per cubic meter

- Sandwich board is made of color coated board, stainless steel and other materials as the surface of the composite board, because of its unique dust, anti-static, anti-bacterial effect, is widely used in electronics, pharmaceuticals, food, biological, aerospace, precision Equipment manufacturing and scientific research on the indoor environment demanding clean engineering areas

- Q:Sound insulation and polystyrene insulation board which sound insulation better?

- The best bamboo pole, or plastic, aluminum alloy, then there is no child at home can have a child, then it is dangerous to fall easily hit people

- Q:Why extruded board (XPS board) is the best insulation board material

- Scaffolding from the erection of the main points on the scaffolding, cantilevered scaffolding and climbing three. High-level general use of floor and cantilever set of set enough to set the dumplings rush to set off the boat to Long. If the number of layers to more than 30F, and the structure can be relatively simple climbing scaffolding, climbing the advantage of the higher the height of the higher relative to the cost of picking. I am a professional scaffolding company, do not understand can ask me. I hope I can help you.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Thermal Extruded Polystyrene board/XPS insulation foam panel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords