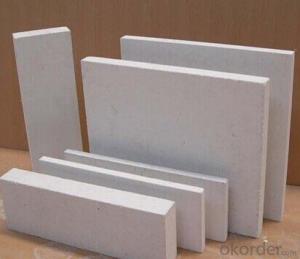

The production department smooth magnesium oxide board

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The production department smooth magnesium oxide board:

Onekin green board is a kind of environmental-friendly board which is widely used in construction and decoration.

It is a new type non-flammable material made of lightweight materials. It's made from magnesium oxide, magnesium

chloride, fly ash , plant fiber etc. the highly purified MgO is used as the main fireproof material, fly ash and

plant fiber as filling materials, the high quality MgC12 as the main cementing material to solidify other

materials.

1,Superior Fireproof Performance

Non-combustible panel, not combusted at 800℃ and no flames at 1200℃

2,Waterproof

Stable physical performances will not be effected even in cold-dry or humid weather conditions.

3,Environmental

Asbestos free, No radioactive elements like formaldehyde, benzene etc and no irritating harmful odor

4,Lightweight and anti-seismic

Lightweight characteristic lowers the interior wall weight up to 60% of the building, increasing the usable areas

5,Sound and heat insulation

Outstanding sound-insulating and heat-insulating (energy-saving) performances provide a cozy living atmosphere.

Details size:

| Raw Mterials | MgO, MgCl2, fiberglass mesh, non-woven cloth | ||

| Standard Size(mm) | Density(t/m³) | Weight(kgs) | Loading pieces(20GP) |

| 2440×1220×3 | 1.0-1.2 | 11 | 1360pcs |

| 2440×1220×4 | 1.0-1.2 | 13 | 1240pcs |

| 2440×1220×5 | 1.0-1.2 | 15 | 1008pcs |

| 2440×1220×6 | 1.0-1.2 | 18 | 850pcs |

| 2440×1220×8 | 1.0-1.2 | 24 | 640pcs |

| 2440×1220×9 | 1.0-1.2 | 26 | 572pcs |

| 2440×1220×10 | 1.0-1.2 | 28 | 512pcs |

| 2440×1220×12 | 1.0-1.2 | 34 | 420pcs |

Physical Properties:

Item | Size | Standard Documents | Standard value | Test Value |

Fireproof | 2440×1220×8mm | GB8624-2006 |

| A1 |

Density | 2440×1220×8mm | Jc688-2006 | 1.0 t/m³<ρ<1.2 t/m³ | 1.17t/m³ |

Flexural Strength | 2440×1220×8mm | Jc688-2006 | ≥10MPa | 11.8MPa |

Impaction resistance | 2440×1220×8mm | Jc688-2006 | ≥2.0 kJ/m² | 5.9kJ/m² |

Water content | 2440×1220×8mm | Jc688-2006 | ≤8% | 2.8% |

Drying shrinkage | 2440×1220×8mm | Jc688-2006 | ≤0.3% | 0.3% |

Wet inflation | 2440×1220×8mm | Jc688-2006 | ≤0.6% | 0.39% |

Screw holding | 2440×1220×8mm | Jc688-2006 | ≥20N/mm | 76.5N/mm |

Anti-halogen | 2440×1220×8mm | Jc688-2006 | No water drop, no damp | Pass |

Chloride content | 2440×1220×8mm | Jc688-2006 | ≤10% | 7.2% |

application:

interior Applications: Exterior Applications:

1) Wall board 1) Sheathing

2) Backer board 2) Soffit- Ventilated and Non Ventilated

3) Underlayment 3) Siding

4) Fireproof board 4) Trim materials

5) Ceiling board

1,Fireproof Grade A1

6mm: ≥1 hour

6-12mm:1-2 hours

12mm : ≥2 hours

2,Water absorption: about 18%

3,Expansion in water:≤0.3%

4,Sound insulation: 29 dB (6mm)

5,Thermal conductivity: 0.161 W/(mK)

6,100% asbestos free

7, No toxicity

8,Resistance to growth of mold and mildew

9, Insect-resistance

- Q:I heard that the overall customer closet is a high density board, and in Sophie is the MDF, is it true that the two plates in the end which is good, the price?

- Some people do not understand the difference between the two types of plates: MDF is better than particleboard: 1, when the plate is relatively thin, MDF elasticity is good, which is why the MDF has 5% of the backplane, and the particle board only 9% of the reason. 2, MDF easier to do than the particleboard shape. MDF is better than particleboard: 1, with imitation wood properties, good waterproof performance. Water absorption rate of 5% to 8%, low expansion coefficient, the density board is best to maintain non-absorbent, high swelling after water absorption, internal perishable. 2, grip nails strong, homogeneous particleboard is solid wood particle board, can be repeated about 10 times. MDF no more than 5 times, because the MDF is powder, once drilled, it forms a hole, the particle board will not, it is wood fiber. 3, stability, compression resistance than the density board. Environmental protection, many people say that the board is better than the MDF board, in fact, are E1 level, it should be almost. Only the same level of E1, MDF production costs must be higher than the particleboard, because the density board wear glue, but also environmental protection, must use environmentally friendly glue, the cost of natural high. For people who buy wardrobe furniture, the particleboard is definitely better than the MDF. Most of the wardrobe business are pushing MDF, because the MDF cost is high, the price is high on the grounds, but slander the particleboard for those reasons a little let people can not stand. China's best particleboard is Jilin forest workers, is a professional production of particleboard, but the streets too many fake, the best look at the prospective buy. Daya's flagship product is the MDF.

- Q:How to get rid of formaldehyde in furniture sheet?

- Formaldehyde capture agent Into the new home, the new office, the newly renovated shops, there will be dazzling, pungent, throat discomfort, which is caused by formaldehyde. Formaldehyde (HCHO) has been recognized by the World Health Organization as carcinogenic and teratogenic substances, is recognized as allergic sources, can cause respiratory diseases, women's irregular menstruation, neonatal malformations, acute mental depression, severe can lead to respiratory, , Gastrointestinal cancer. At present, the visible formaldehyde trapping agent can penetrate into the artificial plate to produce active adsorption, capture and react to formaldehyde free molecules. Once the reaction produces non-toxic polymer compounds, it will never decompose, so as to achieve the purpose of rapid and effective elimination of formaldehyde. Special Note: The product is simple to operate, sprayed on a variety of man-made sheet surface and furniture on the back and back. Price reference: 600ml loaded for 68 yuan (Tianyun licensing).

- Q:So steel products can be called steel, plates and profiles are steel classification.

- Steel: is the ingot, billet or steel through the pressure processing made of various shapes, sizes and performance of the material. Steel is widely used, wide variety, according to the different shape of the cross-section, steel is generally divided into profiles, plates, pipes and metal products four categories, steel is steel ingot, billet or steel through pressure processing made of various shapes, sizes and performance s material.

- Q:What are the characteristics of spruce plate?

- Strong pine wood] to answer your questions about wood! ?? Spruce, also known as European white pine, its fine texture straight, material stability, not easy to deformation cracking, strong resistance, while easy to planing, planing the surface after the smooth, bright, can absorb paint and colorants, and Easy to glue. It itself has a soft color, fine texture and natural texture is very natural into the furniture design, showing a simple original beauty. Spruce has a variety of advantages and uses a wide range, has been hailed as "the Nordic green diamond." ????? Main use: furniture components, housing ceiling, decorative keel, floor, shutters, cabinets, wall panels, musical instruments, organ tubes, boxes, wooden barrels, joinery, cutting wood, sleepers, building structural materials, Bridges and other timber.

- Q:I decorate the home, there are three kinds of programs. 1. buy the general color of the panel, and then brush the water paint. 2. Buy the general panel, brush paint. 3. buy pvc board. You help me count, which is easy to use, which cheap (wages and materials), which effect is good, which is good quality, can be used longer?

- PVC board is PVC as raw material made of cross-section for the honeycomb mesh structure of the plate. Is a vacuum plastic film, used for all kinds of panel surface packaging, it is also known as decorative film, with film, used in building materials, packaging, medicine and many other industries. Which accounted for the largest proportion of building materials industry, 60%, followed by the packaging industry, there are several other small-scale application of the industry. According to the degree of soft and hard can be divided into soft PVC and hard PVC. According to the production process can be divided into PVC crust foam board and PVC free foam board.

- Q:Look at the Internet to say that formaldehyde harm big, how to determine the formaldehyde in the furniture sheet is not excessive? Is there any formaldehyde-free furniture?

- If the new purchase of furniture irritating smell larger, may be caused by high formaldehyde content, if you suspect that the new formaldehyde content of furniture is too high, there are two ways to verify, identify. The first is to see the use of furniture manual, the state has a mandatory standard requirements of the statement will be harmful, toxic limit marked out. But also allows manufacturers to produce product testing report, which usually have formaldehyde content of the mark. Second, the furniture is sent to the City Quality Inspection or other qualified testing organizations to determine whether the formaldehyde content exceeded. Temperature engineers to remind the public to buy furniture to try to large formal furniture shop to buy regular manufacturers of furniture, so that the quality of furniture and other parameters are relatively guaranteed.

- Q:Home decoration do want to do the solid wood doors and cabinets, but also the package side of the package, but it is said that easy to deformation if the use of solid wood inside the panel with solid wood panels, then it will stick with environmental performance as solid wood, but not easy to deform it to see the market with pine materials A lot of everyone is what advice next week on the woodworking undecided ah.

- I am in the harbor of the easy, Jindian home that bought the board, 263 a camphor wood used to do the closet, the door I made to order. Carpenters do the door as the outside to buy good-looking, I think it, do the door with solid wood is not very good, easy to deformation. My colleagues use the solid wood board to do, the results just renovated, not married door on the deformation, but not great, maybe the carpenter's craft not work right I intend to go out to do, do at least better than to do, quality how we do not know, say that the door inside the basic we have also used their own carefully, basically did not say that is bad!

- Q:Novice: stainless steel plate calculation and weighing what is the meaning? more specific

- Stainless steel plate calculation and weighing the meaning of stainless steel through the length of the width and wall thickness using the formula to calculate the weight of stainless steel. The pounds are rated directly to the scales that weigh the stainless steel. Stainless steel can be used as a reference. The actual delivery is subject to weight. In fact, it should be said that the price of pounds than the expensive calculation Because the weight of the calculation will be heavier than the actual weight. Probably the actual: 1: 0.92 Attached to the formula: Stainless steel square tube calculation formula: (length + width -2 times wall thickness) * wall thickness * 0.0158 = kg / m Where the length, width, respectively, refers to the long side of the square tube and short side, the unit is mm. Stainless steel tube calculation formula: (diameter - wall thickness) × wall thickness × 0.02491 = kg / m The unit is in millimeters. The above weight is for 304 stainless steel. Can be used as a reference. The actual delivery is subject to weight.

- Q:Blockboard specifications Why is 2.44 * 1.22M, is the system board specifications on the board so much, or decoration industry in the size of the use of more convenient and so on? I want accurate information. Thank you

- China's norms on the construction modulus to do the provisions should be 3,30 or 300 integer multiple, 2.4 meters 1.2 meters are 300 multiple. We all know that "long carpenters, short blacksmith" this phrase it, in fact, is afraid of the edge of the bumps caused by the whole sheet is not enough size and waste. For the artificial wood board in line with the modulus on the basis of an increase of a protection side, so the formation of the current 2.44 × 1.22 meters of this size.

- Q:What is the material of the deer river?

- Lucy River is now the production of plate varieties are very much. Finger plate. Multilayer board. MDF, melamine board. Plywood. Decorative panels. Particleboard. Building film. and many more. What materials to see what products.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

The production department smooth magnesium oxide board

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords