The Lightgage Rolled Steel Joist Manufacturer

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Description for Steel Joist

Material: galvanized steel

Zinc coating: from 100~275g per square meter

Yield strength 400mpa.

Raw materials : ZINC coating from 80 to 275 gram per square meter .

Thickness : Form 0.50mm to 2.0mm .

Dimension : Length : up to 11.85 meters ,Width : From 40mm to 250mm and Hight from 30mm to 80mm

(1) Lightweight and high strength: 3-4 kg/m2 (1/10 of half brick wall), with yield

strength 400mpa.

(2) Environment-friendly : galvanized steel-no radiation, have no harm to our health

and not pollute the environment.

(3) Products with fillisters : Setting some fillisters in both sides of the keels in a

selective way, in order to strength the keels' vertical points and intensity.

(4) The metal stud with hole : one of our product is the special hole on C-stud

every 600mm, which is easy for workers to install the electric lines and water tubes.

(5) Various sizes of metal track and metal stud : we are able to manufacture

German, Japan and Aus-American types etc..We can meet your customized demands.

(6) Factory direct sale price : We have our own factory to produce raw materials----galvanized(zinc coated) steel, as well as the product line, so we can provide you a lowest

price.

3.Image

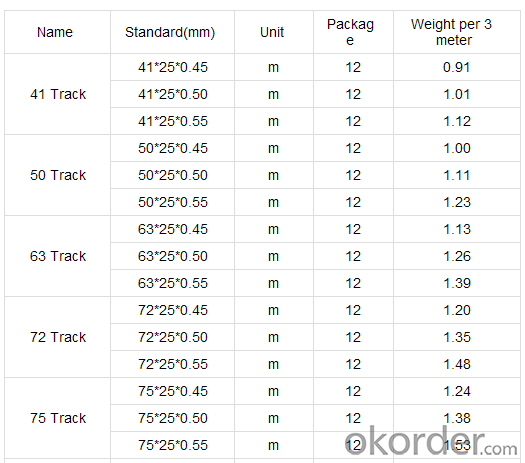

4.Detailed Specification

5.FAQ

1.Environmental friendly

2.Non-combustible

3.Strong nail holding power

4.Heat & sound insulation

5.Smoothness ceiling board

6.Light weight in unit acreage

7.Square Edge or Tapered edge ceiling board

- Q:Decoration light steel keel ceiling in the side of the keel main keel vice keel What is the meaning?

- The side keel is used for fixing to the wall, with the keel connected with the keel, the main keel connected to the pole to connect the vice keel.

- Q:I see the world are now light steel keel, that before the aluminum alloy keel is now out of date? What is the difference between aluminum alloy keel and light steel keel? Are there any market for aluminum alloy keel?

- The main difference between aluminum alloy keel and light steel keel is that the material is different. Light steel keel is made of iron, aluminum keel is made of aluminum, light steel keel is generally U or C type, aluminum alloy keel mostly T-type. Aluminum alloy keel, is the indoor ceiling decoration commonly used in a material, can play a stent, fixed and beautiful role, aluminum alloy material. With supporting the calcium calcium board and mineral wool board, calcium silicate board and so on. Light steel keel, is a new type of building materials, with the development of China's modernization drive, light steel keel is widely used in hotels, terminals, bus stations, stations, playgrounds, shopping malls, factories, office buildings, old buildings Building renovation, interior decoration, roof and other places. Light steel (paint) keel ceiling with light weight, high strength, to adapt to water, shock, dust, noise, sound absorption, constant temperature and other effects, but also has a short duration, easy construction and so on.

- Q:140 square meters light steel keel double gypsum board ceiling fee, material costs about how much money

- The general cost of about 4,000 materials, first-line brand of materials costs around 7000, labor costs about 3000-4500 between ...

- Q:Light steel keel gypsum board ceiling lamp how to install

- This is not the most basic process? Cutter to open the downlight to buy the LED is the external spotlight effect is kind ~

- Q:Will the use of light steel keel and gypsum board ceiling decoration home ceiling, how much money ah?

- Capital of about 50 yuan per square meter cost. Around the artificial may be a bit different, I tell you how to calculate your own combination of your local manual about to know, home improvement with gypsum board per square capital 9 yuan, light steel keel capital per square 10 yuan, artificial 25- 30 yuan per square, plus a few dollars of accessories and losses, it is so simple

- Q:Light steel keel ceiling boom and whether the strong electric lines can be common

- Absolutely not, for security reasons, or not easy to map.

- Q:Light steel keel ceiling which brand is better

- Domestic dragon card can, foreign brands have Lafarge, Jieke is also good. Above, not advertising, on the matter only - the landlord itself is to do building materials, should not know it?

- Q:Light steel keel gypsum board ceiling technology

- 1, U-type light steel keel expansion bolt fixed. 2, 9mm thick plaster board cover, self-tapping screws fixed, nail eye coated anti-rust paint. Gypsum board seams filled with slag gypsum, paste a special bandage. If you switch to waterproof gypsum board, the price plus 20 yuan / ㎡. 3, according to the external plane area calculation of the amount of work.

- Q:Light steel keel ceiling steps? How to use wood?

- You should also have a lantern with a lantern. The board is the lantern

- Q:Is the thickness of the light steel keel related to the height of the ceiling?

- Light steel keel selection with the weight of the ceiling, rather than height.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

The Lightgage Rolled Steel Joist Manufacturer

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords