Termite-repellent and Rodent-repellent Nylon Jacket Compound for cables

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 350 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Nylon compound:

1. Competitive price

2. Customized products

3. Stable quality

4. 30 years of experience

Nylon compound:

1. Applications of Nylon compound:

Used for power cable with large size, owning well performance of resistance to brittleness.

2. Description of Nylon compound:

This nylon jacket compound, based on PA6 resin, is produced and pelletized by special technology with adding special modifier, anti-oxidant and other special additives. It has advantages of processing easily, low temperature resistance, cracking resistance, and smooth surface, termite-repellent and rodent-repellent.

3. Processing of Nylon compound:

The compound can be processed with conventional extruders. The L/D should be greater than or equal to 25; and the compression ratio of screw should be greater than 1:2.5.

Drying: be dried at 85-100°C for 3-7 hours before use.

The following temperature(°C) profile of extruder is recommended:

Zone | Zone 1 | Zone 2 | Zone 3 | Zone 4 | Head | Die | |

PA1001-D | temperature °C | 230 | 240 | 245 | 245 | 240 | 235 |

PA1001-A | temperature °C | 230 | 240 | 245 | 245 | 245 | 245 |

PA1001-S | temperature °C | 230 | 245 | 245 | 250 | 250 | 255 |

Note: The above temperature is recommended only, and the actual processing temperature should be according to the type of machine and environment.

4. Storage and transport of Nylon compound:

Packaging:25kg/bag,Aluminum foil and PE membrane inside bag, and kraft outside bag.

Storage and transport: Avoiding in direct sunlight and weathering. The storage place should be in clean, cool, dry, and ventilated conditions.

5. Properties of Nylon compound:

Item | Unit | PA1001-A | PA1001-D | PA1001-S |

Standard | Standard | Standard | ||

Density | g/cm3 | 1.14 | 1.12 | 1.14±0.01 |

Hardness | ≥Shore D | 68 | 68 | 65 |

Tensile Strength | ≥MPa | 60 | 50 | 50 |

Elongation at Break | ≥% | 160 | 160 | 50 |

Notched Impact Strength | ≥KJ/m2 | 20 | 20 | 6 |

Volume Resistivity | ≥% | 1.0×1012 | 1.0×1012 | 1.0×1011 |

Dielectric strength | ≥MV/m | 24 | 24 | 24 |

Oxygen Index |

| — | — | — |

Melting point | °C | — | — | -- |

Heat distortion temperature | °C | — | — | -- |

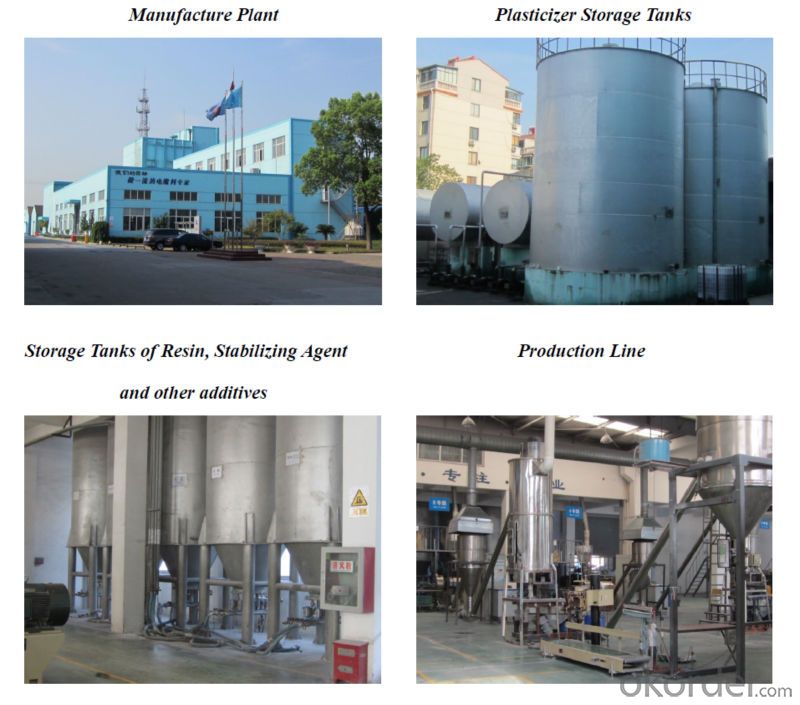

6. Company

- Q:I do PA, PC, PP and other plastic raw materials can be used in the eye frame and lens it

- In general, the lenses of PC need to be covered with scratch resistant protective films, which will be sufficient for better aging, and most lenses for children.

- Q:How many kinds of plastic do you have?

- A. reinforced plastic:Plastic material can be divided into granular (such as calcium plastic reinforced plastic), fiber (such as glass fiber or glass cloth reinforced plastic), sheet (such as mica reinforced plastic) three. According to the material can be divided into cloth reinforced plastic (such as rags or reinforced asbestos reinforced plastics), inorganic mineral filled plastics (such as quartz or mica filled plastics), fiber reinforced plastics (such as carbon fiber reinforced plastics) three

- Q:What is the specific material for plastic pallets?

- With excellent mechanical properties, its strength and elasticity are higher than HDPE, and it has good flexural fatigue resistance. It has good heat resistance and good chemical stability. Besides being concentrated by concentrated sulfuric acid and concentrated nitric acid, it is relatively stable to other chemical reagents. The high frequency insulation performance of polypropylene is excellent because of its almost no water absorption, so the insulation performance is not affected by temperature.

- Q:Will plastic raw materials (such as PET, PP, etc.) be made of non-woven fabrics, will certainly contain BPA?

- BPA doesn't come out of thin air. PC uses BPA as raw material, so it comes with a little bit. Most plastics do not contain bpa. If you need to verify, you can test it and then ask the supplier to verify it. The electronic industry has done so, every level to find upstream suppliers signed a certificate of protection. We should ensure that mobile phone materials do not contain BPA, plasticizers and more than 150 substances.

- Q:What can be added to the PP plastic material to prevent light transmission?

- Join the black color on the line! Plastic is black to prevent light from passing through

- Q:Can PE material be used as food grade plastic?

- Yes, but the raw material suppliers have already divided the ingredients into food grade, and they will be used in non food occasions to contain substances harmful to the body

- Q:What is the disposable transparent plastic cup?

- PMMA: commonly known as acrylic, transparent material, its surface hardness is slightly lower, easy to wipe flowers. It is suitable for making transparent insulation parts and general strength parts

- Q:Raw materials for making plastic bags

- Polyethylene (Polyethylene, PE), referred to as PE. It is a high molecular organic compound which is made up of ethylene. Polyethylene is recognized as the best food for contact with food in the world. Non-toxic, tasteless, odorless, in line with food packaging hygiene standards. Polyethylene film, light and transparent, with moisture-proof, anti - oxygen, acid, alkali, air tightness, heat sealing and other outstanding performance. Known as "plastic flower" laudatory title. It is the most important and most important material in plastic packaging and printing.

- Q:What kind of material is the raw material of plastic pipes?

- Plastic pipe raw material is plastic particles, according to the pipeline production processing performance requirements, with the different requirements of finished products, there are different manufacturers grades, grades and performance differences.

- Q:What are the raw materials for plastic products? Resin or oil?

- Molded plastic: a resin mixture for molding. Such as thermosetting plastics.Laminated fabric: a fabric impregnated with a resin that can be laminated and pressed together to form an integral material.Injection, extrusion and blow molding plastics: - refers to a mixture of resins that can melt and flow at the cylinder temperature and rapidly harden in the mold. Such as general thermoplastic plastics.Casting liquid: a liquid resin mixture that can be poured into a mold and hardened into a definite shape in case of no pressure or little pressure. Such as MC nylon.Reaction injection mold plastic: generally refers to liquid raw material, pressurized injection mold cavity, so that the reaction of curing, finished products. Such as polyurethane.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Termite-repellent and Rodent-repellent Nylon Jacket Compound for cables

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 350 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords