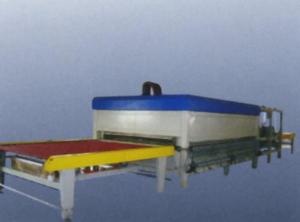

Tempering Furnace-6

- Loading Port:

- Dalian/Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 3 set/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Glass tempering furnace.Mainly termpering glass for domestic furniture,appliances,architectural decoration,shower booths,autombile,trains,ships,etc

- Q:How to polish plexiglass and acrylic machine after machining?

- The combustion of hydrogen and oxygen for combustion, flame, zero pollution, high production efficiency, the flame is not pure blue smoke and dust, especially suitable for polishing organic glass, acrylic and other materials, is one of the necessary equipment for making crystal characters, so it is also known as organic glass flame polishing machine

- Q:I'd like to open an art glass processing factory. What equipment do I need?

- Find a glass art processing factory to work for a period of time, process and equipment do not know, the enemy can ever victorious, I also want to do glass processing technology, but no money, can only think of.

- Q:How much do you charge for a set of insulating glass processing equipment?

- Mainly processing aluminum strip type of insulating glass; 3 cleaning dryer and hot melt adhesive machine, mainly processing hot-melt adhesive hollow glass.

- Q:Status of glass machinery for glass machinery

- By the beginning of twentieth Century, there appeared the trend of following glass processing enterprises. Foshan, Shenzhen, Guangzhou, Shanghai, Hangzhou, Suzhou, Zhangjiagang and other relatively concentrated industrial areas have emerged. Its development area has expanded to the Shandong Peninsula to the Bohai rim area, and has spread to many cities in the mainland. At present, more than 50% of our country's glass cold processing equipments are manufactured in Guangdong and Shunde.By 2014, the development of glass machinery in China was highly dependent on the international market.

- Q:What are the mechanical equipments of float glass production line?

- Finished processing line: glass plate after annealing with continuous processing into the finished product line, through the shower water washing, drying, scanning, detection, slitting, cutting, breaking, and go to the side, according to different dimensions, and then by fetching device, automatic film fetching, stacking and packing paper. The cut edge and unqualified glass are broken and sent to the broken glass system by belt conveyor.

- Q:How much money do you need to invest in making glass hot bending? What equipment should I buy?

- It depends on what kind of hot bending glass you want to make, depending on the size of the glass

- Q:How much does a set of insulating glass aluminum strips require?

- Hollow glass aluminum bars in the past few years, the market is relatively hot, but the equipment requires high accuracy, it is estimated that the price is not cheap.

- Q:The factory is doing glass deep-processing, and now want to purchase glass deep-processing equipment, glass grinding machine is now required, I would like to ask you have manufacturers recommend it?

- Before starting, connect the pump, fill up the water, turn on the machine and observe whether the belt is turning. Under the correct circumstances, is the water pump adequate? If it is not correct, replace the two lines in the power supply.

- Q:What are the processing methods of organic glass?

- Important points in hot bending of perspex:A. if you want to use water heating, do not "direct" heating by boiling, and use indirect heating so as not to change the size after moisture absorption.B. fixtures should be "level, smooth and clean" so as to avoid residual plastic lines and affect transparency.C. heating rate should not be too fast, should not exceed the thermal deformation temperature.D. cooling, the temperature of each part of the workpiece should be consistent. So the cooling rate is not too fast, otherwise heart with epidermal temperature difference caused by thermal stress, loosen fixture after deformation and back. Therefore, the cooling rate should not be too fast, the furnace will be better cold.The size of the E. after heat treatment will change slightly due to the two contraction, and the temperature should not be too high to reduce the shrinkage size.F. don't iron it, it will deform much more!G. specific heating time and temperature, it is necessary to experiment several times in order to master the best temperature, time.

- Q:Where there is a machine for processing glass, that is, you can empty an empty wine bottle into a crystal, or a bead

- The material of the utility model is processed by the blank with little amount of grinding, and the melting and refining standards are very high, and the color, purity and transmission are transparent...It's not ordinary glass. It can be counterfeited.If it could have been done hundreds of years ago.

We are a professional, experienced ,hi-tech enterprise, specialized in developing and manufacturing glass tempering systems .in the past years ,it has been engaged in the research and development of deep processed glass products and equipments.

1. Manufacturer Overview |

|

|---|---|

| Location | Qinghuangdao, China |

| Year Established | 2002 |

| Annual Output Value | US$ 5 Million - US$ 10 Million |

| Main Markets | North America; South America; Eastern Europe; Southeast Asia; Africa; Oceania; Mid East; Eastern Asia; Western Europe; Northern Europe; Southern Europe |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Tianjin; Qingdao |

| Export Percentage | 91% - 100% |

| No.of Employees in Trade Department | 3-5 People |

| Language Spoken: | English, Chinese |

| b)Factory Information | |

| Factory Size: | 5,000-10,000 square meters |

| No. of Production Lines | 5 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Low |

Send your message to us

Tempering Furnace-6

- Loading Port:

- Dalian/Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 3 set/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Hot Searches

Related keywords