Tee Grid for Ceiling Tiles Tee Grid for Ceiling Tiles

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ceiling channel and drywall channel, made of high-quality Snowflakes Steel

Product Applications:

Product used for internal constructions gypsum drywall partition such as hotels, terminal building,

bus station, theatres, shopping malls, factories, office buildings, and etc.

Product used for internal constructions gypsum drywall partition such as hotels, terminal building,

bus station, theatres, shopping malls, factories, office buildings, and etc.

Product used for internal constructions gypsum drywall partition such as hotels, terminal building,

bus station, theatres, shopping malls, factories, office buildings, and etc.

Product Advantages:

1.Light,good strength,cauterization resistance and water resistance

2.Matching magnesium fire-proof board,gypsum board and many other wall and ceiling board

3.Moisure-proof ,shock-resistant,high-effcient and environmentally-friendly

4.Easy and fast for installation,time-saving

5. Prompt delivery, high quality ,competitive price and complete sets of styles

6.We can supply you the products based on your specific requirements

Main Product Features:

(1) Lightweight and high strength: 3-4 kg/m2 (1/10 of half brick wall), with yield strength 400mpa.

(2) Environment-friendly : galvanized steel-no radiation, have no harm to our health and not pollute the environment.

(3) Products with fillisters : Setting some fillisters in both sides of the keels in a selective way, in order to strength the

keels' vertical points and intensity.

(4) Various sizes of metal track and metal stud : we are able to manufacture German, Japan and Aus-American types etc..

We can meet your customized demands.

Product Specifications:

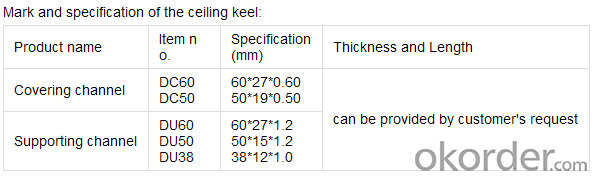

Image

- Q:Light steel keel wall how much money a square?

- Light steel keel skeleton per square meter 20 yuan, gypsum board partition 9 * 2 = 18. Labor costs at 20 yuan, if placed on the noise cotton to add 3, plus loss, other dressings generally around 65 yuan

- Q:Light steel keel ceiling in the card type of the main keel what model

- Cartoon keel is divided into: 23 25 28 32 38 These specifications, the height is generally increased with the model and increased, but because the manufacturers are different models, but the size of the gap is not, should be reasonable Dependable All of the market are these models, but also because of the geographical difference is the selective operation of several.

- Q:Home decoration ceiling light steel keel best use what specifications

- Commonly used wall steel keel specifications are 75mm and 100mm, the length of 3m and 4m; ceiling with light steel keel The specifications are 50mm and 60mm, and its length is also 3m with 4m. More than the specifications of the light steel keel, then Need to customize the commonly used wall with light steel keel specifications are 75mm and 100mm, the length of 3m and 4m; ceiling with light steel keel The specifications are 50mm and 60mm, and its length is also 3m with 4m. More than the specifications of the light steel keel, then Need to be customized

- Q:How much should it cost to install approx 550 sq ft of drop ceiling (parts and labor)? Can you quote approximate cost, parts and labor separately...Thanks in advance!

- Get three estimates from Trane, American standard and Rheem/Rudd, all just right models. Might be 7500 and up established. Ducts within the crawl house will add 3500 for sheet steel pipe, 2500 for flex duct. There are further bills for stats, removing, pads, copper line set, vents/registers for one other 1500. You can also desire a 3 ton however a website visit for a load calculation is imperative. These are simply estimates however not a long way off. I'd let the other bidders comprehend who you're inquiring for bids from they usually may reduce one of the most cost down to compete. Additionally, ask each person you already know who they used earlier than. Get referrals from the contractors which might be recent, like final summer or fall.

- Q:Light steel keel wall is this use?

- Is such a pendulum. The actual keel is to be on the ground when the keel is to be fixed, the vertical keel to use the keel clamp fixed in the ground on the keel, and the vertical keel will have a hole from time to time, it is put through the keel The And then to the top of the horizontal keel should also be fixed with the top.

- Q:Can you touch up drop ceiling tile with paint ? I don't want to remove a tile for a scratch or scuff.?

- This Site Might Help You. RE: Can you touch up drop ceiling tile with paint ? I don't want to remove a tile for a scratch or scuff.?

- Q:I am finishing my basement and want to do drop ceiling. Problem is I don't want to spend an arm and a leg doing it. I have checked with Home Depot and Lowes and it seems like I might have to. Does anyone know of any other options? Thanks.

- Cheap Ceiling Tiles

- Q:The difference between wall steel keel and wall keel

- The wall steel keel is composed of 75 main bone and 38 through the heart

- Q:Attached photos can be added points

- Simply said light steel keel is iron made of aluminum keel is made of aluminum light steel keel is generally U or C type aluminum alloy keel mostly T-type. But there is a kind of paint keel is made of metal. Also T-type. But relatively soft. Light steel keel is generally used in the veneer, that is, keel seal gypsum board in the paint, aluminum alloy in the frame more, paint keel, aluminum, mineral wool board, aluminum alloy keel cost is expensive Light steel keel prices are relatively first in almost all with light steel keel, light steel keel is the load keel, the general model is DU50, DU38, DU60 aluminum alloy keel just with 60 * 60 silicon calcium board with, divided into large T and T and Corner. Light steel keel is a paper gypsum board; silicon calcium board; cement pressure plate and other smallpox material base fixed material. Light steel keel is generally in accordance with national standards for production and processing.

- Q:does anyone know where I can find clips to hang things from acoustic ceiling grids?

- use bent out paper clips...

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Tee Grid for Ceiling Tiles Tee Grid for Ceiling Tiles

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords