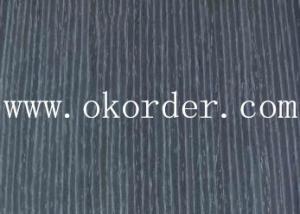

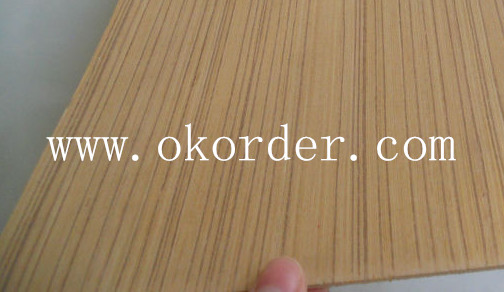

Teak Engineered Wood Veneer

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 200000 SQM m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of the Teak Engineered Wood Veneer

| Name | Teak Engineered Wood Veneer |

| Type | sliced |

| Length | 2200-3100mm |

| Width | 320-900mm |

| Thickness | 0.15-1mm |

| Thickness tolerance | 0.02mm |

| Grade | A/A Grade |

Instruction of the Teak Engineered Wood Veneer

Teak Engineered Wood Veneer is sliced reconstructed real wood veneer, it is made from nature

timber which color is enhanced,reformed to a square and then re-sliced into rectangular veneer

sheets.

The usage of the Teak Engineered Wood Veneer

The engineered wood veneer is applicable for modern new decoration and traditional classic

decoration. And now the engineered wood veneer has mainly developed the following techinical

wood of white oak serious, red oak serious, ebony serious, res sandalwood serious,soluble red

wood serious,zebra serious, cherry serious, walnut serious,wenge serious, and so on. Several

serious and ten of types have been promoted to the markets and hundreds of types are in our

technical storage.

Popular of the Teak Engineeres Wood Veneer

Various types and colors of the The teak engineered wood veneer meet the increasing

individual consumption needs of people. There is at last one type suitable for your selection,

the engineered wood veneers saves your material cost on residential decoration and prevents

you from the trouble of difficult and impossible connection resulted from texture and color of

nature wood. You can make good use of each raw material that you bought.

The following pictures for your reference.

- Q:Veneer should pay attention to the different production processes

- In fact, science and technology veneer is the original wood. According to comprehensive survey, furniture enterprises have different misinterpretations of the technology veneer has three aspects.

- Q:Slicing of thin slices of wood

- Of the wooden side should be promptly placed in the paver before the wood temperature of the tank,

- Q:What can the veneer be classified?

- according to the manufacturing method of classification Can be divided into sliced thin wood; peeling veneer; sawing thin wood; semi-circular peeling veneer. Often the use of slicing method

- Q:What is the veneer process?

- Such as the use of Wan Nengjiao, not environmentally friendly, easy to blister on the paint, arc when the veneer is easy to break,

- Q:Advantages and disadvantages of Technology veneer and natural veneer

- In personal terms. Science and technology veneer in the next few years will be to a certain extent, replace the natural veneer. hope this helps. Pure hand hope to give points. You can also ask

- Q:Wooden door with veneer ruled, pattern is produced by different cutting methods

- According to the data of the broadleaf plywood and veneer association, the standard cutting method for the veneer used in the market is as follows

- Q:A lot of Advantages of veneer

- The same mild touch as the logs. More economical than the logs, low prices. Easy to apply to all kinds of body, painting versatility.

- Q:The principle of veneer dyeing

- can also play creative special color (ordinary oil qi effect will only cover the wood itself should

- Q:Brief description of veneer production process

- Of the wooden side should be promptly placed in the paver before the wood temperature of the tank, the insulation in the range of 40 ~ 50 ℃ (with the species and thin wood thickness may be).

- Q:Different veneer has different production processes

- Some companies further speculate that the technology may be the use of chemical raw materials made of chemical raw materials or decorative decorative finishes.

1. Manufacturer Overview |

|

|---|---|

| Location | Shandong,China |

| Year Established | 2004 |

| Annual Output Value | Above US$6 Million |

| Main Markets | Mid East;Eastern Europe |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Lianyungang;Qingdao |

| Export Percentage | 81%-90% |

| No.of Employees in Trade Department | 50-100 People |

| Language Spoken: | Chinese |

| b)Factory Information | |

| Factory Size: | Above 20,000 square meters |

| No. of Production Lines | 4 Lines |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

Teak Engineered Wood Veneer

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 200000 SQM m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords