Tape Bus Bar Insulation and Corrosion Protection

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 roll

- Supply Capability:

- 100000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of KC71 Tape

• KC 71 is a self-amalgamating ethylene propylene rubber (EPR) tape used on solid dielectric cable for electrical insulation and jacketing in splices up to 69Kv and for building stress cones in terminations up to 35kV.

• The tape comes with a separator that is removed during the taping process.

• Its 0,76mm thickness and quick amalgamation facilitates a rapid, void free insulation build-up that is electrically stable and moisture proof.

• KC 71 is suitable for use with conductors rated at 90°C with an emergency overload rating of 130°C.

• The tape is also resistant to corrosion, chemicals and ultra violet light.

• KC 71 fully meets the Table 1 requirements for Type III tape in ASTM D 4388.

Dimensions of KC71 Tape

1” x .030” x 16.4'

25mm(width) x 0.76mm(Thickness) x 5m(length)

Consult us for other sizes

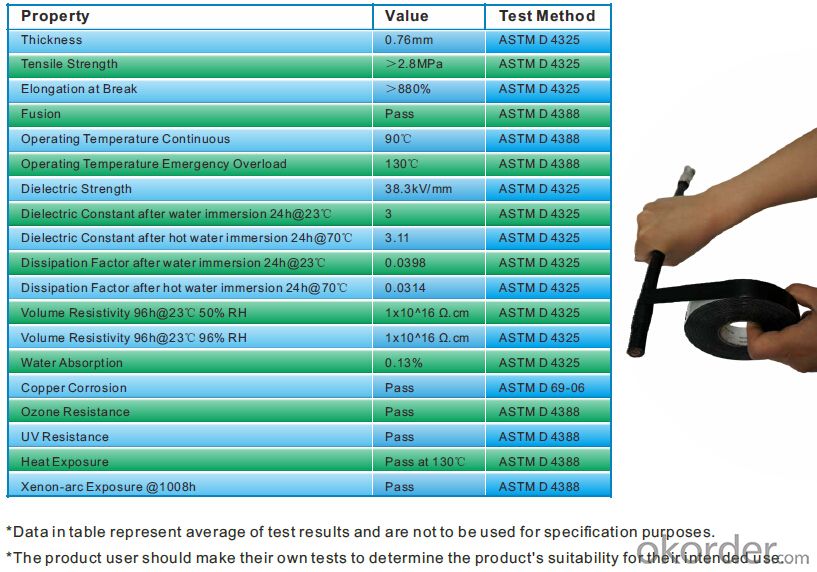

Specifications of KC71 Tape

Applications of KC71 Tape

• Electrical insulation and jacketing in splices of solid dielectric cable up to 69kV

• Building stress cones in terminations of solid dielectric cable up to 35kV

• Jacketing of indoor terminations

• Bus bar insulation and corrosion protection

• Jacket repair and restoration in all types of cable

• Moisture sealing applications

FAQ

Q1.Can we have the customized size tape?

A1:Consult us for other size

Q2:Is this Tape environmental-friendly?

A2:This tape is flame/arec resistance and environmental-friendly.

Q3:Can we have the sample/trail order to test quality?

A3:Surely we support the sample/trail order.

- Q:What materials are used for steel pipe corrosion protection?! How about the anticorrosion effect of PE tape? Or is 3PE's effect better? What's the lower cost?

- You look at the requirements of the project, there are requirements, you must use a 3PE heat shrinkable polyethylene anticorrosive adhesive tape, the cost is low, but the effect is far from 3PE to 3PE, the cost is several times of polyethylene, oil pipelines, gas pipelines, are using 3PE, you can see my ID. To...,... Even,,,,, and then give you a detailed introduction

- Q:What are the functions and types of electrostatic tape?

- It is made of rubber type pressure sensitive adhesive. It has good insulation, fire resistance, voltage resistance and cold resistance. It is suitable for automobile wiring

- Q:Where are the PVC tape coating machines being made?

- Self adhesive (self-adhesive) machine coating machineI. product uses:Mainly used for kraft paper, trademark paper, advertising paper, double-sided tape, PVC, PU, EVA, foam (sponge), beauty paper, non-woven fabrics, fabrics and other raw materials, self-adhesive, self-adhesive, composite.

- Q:What's the name of the tape?

- First of all, the tape, as soon as we hear the name, we are wondering whether it is the raw tape, is it still cooked tape?. In fact, this is not the case, raw tape is also called raw meal belt.

- Q:Purchase insulation tape PVC Slitter

- Oh, Hello, we are doing tape cutting equipment, please ask what you mainly cut PVC series what kind of tape? Electrical tape? Warning tape or double sided tape?

- Q:What's the difference between an electrostatic tape and an PVC tape?

- PVC electrical tape is in soft polyvinyl chloride (PVC) film substrate, manufacture coated rubber pressure sensitive adhesive, has the characteristics of good insulation, flame resistance, voltage resistance, cold resistance, suitable for automotive wiring, wire winding, insulation protection etc..

- Q:PVC are the grades of electrical tape classified? How do you identify the grades?

- B film is between the film and C film, in short, see more, stretch tape, experience will be identified. Of course, in fact, how only manufacturers understand the price of a point of goods, right?

- Q:How to correctly use cold resistant anti freeze PVC electric adhesive tape

- Make sure you don't get stuck; if it's a thick film, take care to stretch the tape, then force it tight and press it firmly

- Q:PVC pipe and duct tape tape what is the difference??

- PVC pipe adhesive tape:PVC pipeline adhesive tape is the base material, PVC material, trade name: anticorrosion tape, pipeline anticorrosion tape. It has a strong bonding force and is very solid,

- Q:What are the uses of black cloth tape

- PVC insulation tape is composed of base band and pressure-sensitive adhesive layer. The base band is made of cotton fabric, synthetic fiber fabric and plastic film. The adhesive layer is made of rubber and tackifier. It has good adhesion and good insulation

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Tape Bus Bar Insulation and Corrosion Protection

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 roll

- Supply Capability:

- 100000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords