Tackifying Resin SL-1408 for Rubber With Good Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 12 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The Description of Tackifying Resin:

1) SL-1408 resin is a superior tackifying resin, which can improve and maintain the tackiness of the compounds especially under the warm and humid conditions. Its tackifying property is equal to that of t-butyl phenol-acetylene resin.

· 2) SL-1408 resin improves the processing properties of rubber compounds. The presence of tackifier molecules on the surface of rubber compounds can prevent the oxidization and hardening of compounds and also, to ensure rubber tackiness and plasticity.

· 3) Curing properties of compounds will not be affected and the physical properties of vulcanizates will not be changed by the addition of SL-1408.

· 4) With the combination of tackifying, plasticizing and softening properties, SL-1408 has the universal compatibility with all kinds of rubber, especially for the manufacture of tire and other rubber articles requiring super tackiness.

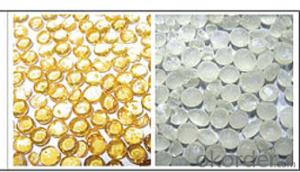

· 5) SL-1408 is supplied in the form of pastilles without dust generation and therefore, much favored in the automatic weighing system. This resin can be easily mixed into rubber compounds and no contamination to equipment and workplace can be expected.

The Main FeaturesTackifying Resin:

1) SL1408 resin is preferably be added during the first stage of mixing to facilitate the uniform dispersion of this product into rubber compounds.

· 2) It is recommended to use SL-1408 resin at 2-5 phr loading. The rubber processing oil level in the compounds can also be reduced properly.

· 3) SL-1408 resin can be extensively applied to natural and synthetic rubbers, to produce high

performance tires, convey belts, hoses, rollers, rubber plates, rubber inner liners, retread materials, wires and cables. This resin also can be used as tackifying agent in adhesives.

The Images of Tackifying Resin:

FAQ:

Q: Can you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 5 tons

Q: What are your payment terms?

A: We accept L/C,T/T, West Union,etc.

- Q:Motorcycle cover rotten, I want to stick back, to be fixed in the car, twisted screw, what glue can be completely sticky tight? I used 502 with a few days and rot

- You can use epoxy tree glue.

- Q:What are the glue for industrial adhesives?

- A single-component adhesive / sealant that can be cured only in the absence of air. For thread locking, cylindrical holding, pipe thread seal, plane seal and so on.

- Q:Plastic (PVC) special waterproof adhesive properties and enhance the performance of what attention

- The pH of the waterproof adhesive must be within the specified limits;

- Q:Adhesives, adhesives, sealants and the role of the same effect? What is the difference?

- The first two should be similar things, sealants belong to another class of material, depending on the application of its role and the effect of the requirements of the big difference, specifically you need to understand what the problem can be made directly to give you more clear Reply.

- Q:What is the cover of white pulp, what is the agricultural shrink to help pulp, what is the color paste, adhesives, chemical fast glue?

- Chemical fiber quick-drying glue refers to the chemical fiber materials for the quick-drying glue.

- Q:How to distinguish between good steak and made from the meat of the "synthetic steak"

- In fact, it is not a big deal, anyway, beef, not the mouse meat, up to spend a little more money only.

- Q:Characteristics and Uses of General Purpose AB Adhesive

- The market are generally acrylic type, in fact, many glue can be ab glue, such as epoxy, polyurethane, silicone and so on.

- Q:The market characteristics of adhesives

- China has entered the world of adhesive and sealant production and consumption power. China's adhesive and sealant production is to scale, intensive direction.

- Q:Will the kind of adhesive soluble in water (preferably powder), melting temperature of about 800 degrees, was neutral or weak alkaline, thank you!

- Sodium alginate was crosslinked with glutaraldehyde under acidic conditions and poured into ethanol solution to prepare sodium dithiocortate containing diclofenac sodium (slightly soluble in water). The embedding rate is 30% to 71%, depending on the preparation conditions. When the ball is prepared, the temperature is increased or the exposure time of the crosslinked substance is prolonged, the embedding rate is reduced and the drug release time is prolonged

- Q:What is the pigment binder?

- 83-BG49660 A composition for the preparation of a degradable polyol polyester, a process for obtaining a polyol polyester, an elastomer, a foam, a coating and a binder, and a degradable.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Tackifying Resin SL-1408 for Rubber With Good Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 12 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products