T-bar Ceiling Suspension Grids

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1,Structure of (ceiling grid for suspension) Description

T32#

Main Tee:32*24*3600/3660mm

Cross Tee:26*24*1200/1220mm

Cross Tee:26*24*600/610mm

Wall Angle:20*20,22*22,24*24mm

Suspension T-grids(T-bar) systerm/tee keel from professional manufacture --Wen'an City Xinxing Buliding Materials Co;Ltd.

Exposed Flat T-grids systerm:

2,Main Features of the (ceiling grid for suspension)

T32#

Main tee:32×24×36003660mm

Cross tee:26×24×1200/1220mm

Cross tee:26×24×600/610mm

Wall Angle:20×20,22×22,24×24 mm

T38#

Main tee:38×24×3600/3660mm

Cross tee:26×24×1200/1220mm

wall Angle:20×20,22×22,24×24mm

3,(ceiling grid for suspension) Images

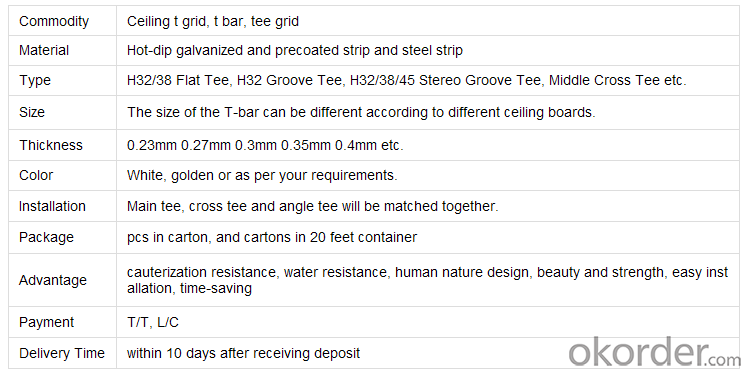

4,(ceiling grid for suspension) Specification

5,FAQ of (ceiling grid for suspension)

Other pattern:

Grooved T-grids with black line,or according to order

Material:galvanized steel strip

Surface treatment:Baking Painting

End:normal lock end & alloy lock end

Advantage:Cauterization resistant,water-resistant,beautiful,easy for fixing

Used with acoustic mineral fiber ceiling tile,PVC laminated gypsum ceiling tile,etc.

Fire-proof hole can be avaliable to order.

OEM service can be avaliable.

Packing:carton

Loading with 20ft container.

- Q:I have just pruchased a townhome that has a basement that was once finished. It has drywall, a drop ceiling grid (is missing tiles), and electrical (outlets and such). I have had basement electrical inspected and we are good to go, i have also had a mold inspection and there is none present. The basement has no flooring (carpet has been removed) and has a basement smell. Other than ceiling tiles, flooring and paint what else would I need to make this basement liveable? Would I need to install a ventilation system? This was at one time a functional finished basement.

- Depending on the region you live in, you should have a dehumidifier running in the basement during the summer months. Make sure to buy one that will drain automatically - you can run the hose to a drain in your basement. This would take care of the normal rise in moisture and therefore prevent the basement from having a musty smell. When finishing the floor, if you prefer carpet, glue it down. If you happen to get water (other than sewage), the carpet can be extracted, dried, and cleaned. Depending on what you plan to use the finished area of the basement for, make sure you have coverage on your insurance policy for water backup or sump pump coverage if you have a sump pump. This is something you can talk to your insurance agent about. The missing ceiling tiles should be easy to replace.

- Q:I am finishing my basement and want to install a drop/suspended ceiling instead of drywalling it. I want the ceiling to be as high as possible but have a bunch of large ducts in the middle of the room. Do I just build a bulk head around the duct work and then put tiles around it or are there a bar system that will do that for me? I just don't want my whole ceiling at the height of the duct work.

- First okorder /?XlinkID=13 Typical drop ceilings need about 4 whereas the CeilingMax mounts flush. As for the ducts, you could box them out with plywood and just paint them with a semi-gloss white paint (or the same as your trim color). I personally wouldn't tile them. If they are square and tight to the ceiling, you could install the CeilingMax right up to the side of the duct and just paint the duct itself.

- Q:I have recently installed a new suspended ceiling. I have scraped or chipped the corners on a few of the tiles when installing it into the grid system. Is there a product available that can be used to touch-up the scraped off paint?

- We usually use white shoe polish to hide the brown material visible from damage in ceiling tiles. You could go through the trouble of trying to fill with a filler material but the texture will never match and it can get messy. Just use either white shoe polish or spackle that comes from Home depot in a bottle with a foam applicator pad at the end, water clean up and white color makes easy repairs

- Q:Light steel keel CB38 * 12 What does it mean?

- Refers to the main keel with 3.8cm × 1.2cm, which is often said 38 main keel. There are 38 holes in the wall

- Q:Our bedroom has 4 recessed lights in the ceiling that form the perimeter of a 6x6 square. I would like to install a ceiling fan in the middle but it would require me to install a new wiring box. Is it possible to tap into the wiring my recessed lights run off of to run my ceiling fan? Or do i need to run all new wiring to my panel? Thanks in advance for your experiences and help.

- Recessed Light Fan

- Q:I have a manufactured home and trying to finish the basement. I am stuck on how to install a ceiling being there are steel beams instead of wood therefor nothing to attach a grid to. Any ideas or anybody ever done this before?

- you could buy screws with a drill point and a hex head.attach with these to the metal beams drop down enough to clear obstacles support grid with wire hung from screws

- Q:Commonly used! Is the use of engineering, hope to tell, thank you!

- Light steel: refers to the use of relatively small steel made of steel, it is characterized by relatively light, but the hardness is great.

- Q:What is the difference between light steel keel and aluminum alloy keel?

- Aluminum alloy keel cost is high Guichang keel prices are relatively cheap in almost all with light steel keel

- Q:Light steel keel ceiling models which

- Wall steel ceiling keel specifications and information decoration materials Light steel keel wall materials are 50, 75, 100, 150 and several other Light steel keel thickness ranging from 0.4mm to 2.0mm.

- Q:Light steel keel divided into several

- Light steel keel according to the use of hanging keel and cut keel, according to cross-section of the form of V-type, C-type, T-type, L-keel. 1) Product specifications series of keel main specifications are divided into Q50, Q75 and Q100.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

T-bar Ceiling Suspension Grids

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords