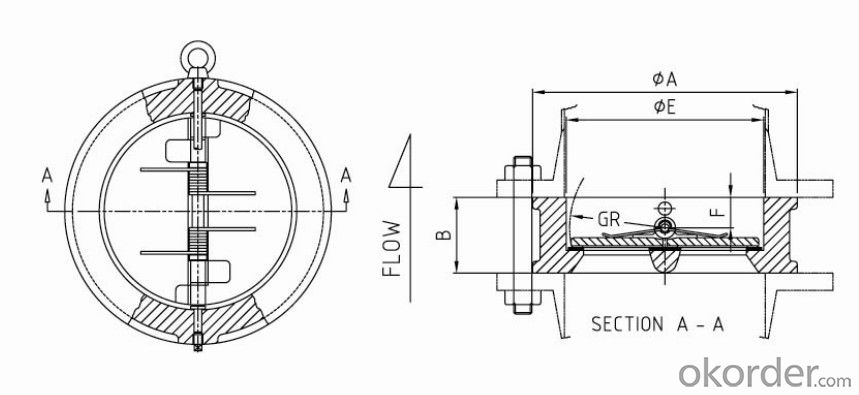

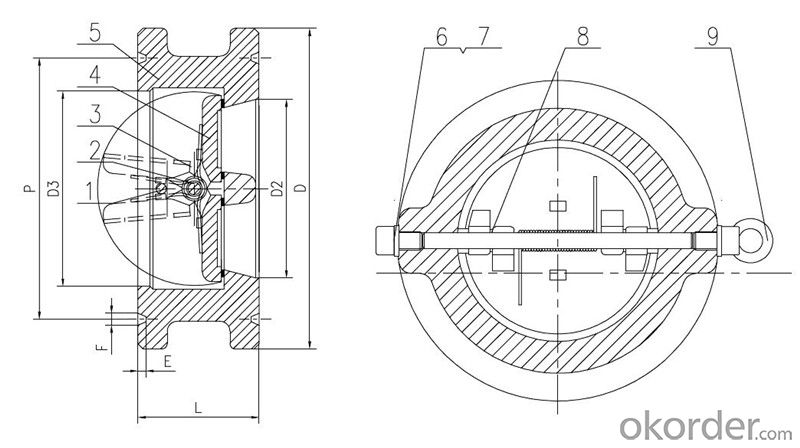

Swing Check Valve Wafer Type Double PN 16 Mpa

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Products Description of Swing Check Valve

Check valves are used in pipes under pressures between PN1.6~16.0MPa(Class150~2500Lb), working temperatures-196~600℃, They are used in industries include oil, chemistry, pharmaceutical, fertilizer, and power gene-ration to prevent the backward flux of the media.

The main structure features of Swing Check Valve:

1、The products feature a reasonable structure, reliable seal, good performance and nice modeling.

2、Either soft or hard seal can be selected for the product upon different working conditions.The sealing face is built up with Co-based

carbide alloy, leaving a better wearability, corrosion and scrap resistance and a longer duration.

3、Small opening pressure, the disc can be opened fully with a very small pressure differential.

4、Inside-set bolt-bearing structure reduces leakage and reliable use.

5、PN≥16.0Mpa (class1500), the middle cavity uses a self-tightening sealing structure to have the sealing performance reinforced along

with the pressure rise so as to ensure the sealing performance.

6、Different parts materials and different sizes for flange, butt-welding are available for sensible combination according to different working facts and customers' requirements.

Parameter of Swing Check Valve:

Standard Criteria | GB customize |

Pressure Rating | 1 Mpa 1.6 Mpa 2.5 Mpa 4 Mpa 6.4 Mpa 10 Mpa 16 Mpa customize |

Valve Size | 50 mm 65 mm 80 mm 100 mm 125 mm 150 mm 200 mm 250 mm 300 mm 350 mm 400 mm 450 mm 500 mm 600 mm customi |

Actuator | Automatic customize |

Connection | Wafer customize |

Medium | Oil Steam Water customize |

Medium Temperature | -196~600℃ customize |

Structural style | Swing double-clack structure customize |

Application Fields | Agriculture Electricity Medical Petrochemical customize |

1-Body Material | CF3 CF8C CF8 WCB CF8M CF3M customize |

2-Disc | CF3 CF3M WCB CF8 CF8M CF8C customize |

3-Pivot | 1Cr13 1Cr18Ni9Ti 0Cr18Ni12Mo2Ti 2Cr13 customize |

4-Spring | 60Si2Mn 1Cr18Ni9Ti 4Cr13 0Cr18Ni12Mo2Ti customize |

Design Standard | GB/T 12224 customize |

Connection Standard | GB/T 9113 HG 20592 JB/T 79 customize |

Test Standard | JB/T 9092-1999 customize |

Face to Face | GB/T 15188.2-1994 customize |

Images of Swing Check Valve:

FAQ of Swing Check Valve:

Q1:I can’t find the type of steel check valve which I need. what can I do?

The chart above only lists out some common composition of steel check valve parts.We may provide other different parts material composition according to the customer's request or the actual valve working condition.

Q2:Which certification do your products pass?

Our products are in accordance with ISO 9001、ISO 14001、API 6A、API 6D、TS CE、API607/6FA/BS6755.

Q3:How can I place an order?

The only one thing you should do is to tell us the sepecification about type 、quantity and mode of transportation, then we will send you quotation within 24 hours.

- Q:Is it safe to remove the butterfly valve on my 94 celica 1.8l st?

- no theres a reason its there,, to regulate air flow...without it your car will get poor preformance..

- Q:Today I found out I have the heart disease Mitral Valve Prolapse. I'm 13, I weigh 109 pounds and I'm 5'8. I'm also pretty skinny too. I know this is a pretty common disease but should I be worried at all?

- Normally, no it is not something to worry about overtly. However if you are not treated properly and not monitored then things can get worse. Your weight actually fits in with MVP as most people with MVP have a low BMI and are quite lean and skinny. If your doctor has put you on a care programme, great if not, voice your concerns to them!

- Q:What is a valve adjustment? I wanted to do one on my 1994 Honda civic ex cuz my friends told me I should do one but I wanted to know howmuch will it cost? And what will it do to my car in performance and gas consumption? My car right now has 155k miles.

- Don't bother if you really don't need it (or don't know what it does). As cars get old, parts wear out and need to be adjusted. The valves open and close to let fuel in and exhaust gas out. unless you are suffering from some problem you don't need it. ==== I have 1994 Civic EX also. The good news is that the valves are very easy to access so the labor is cheap (no new parts unless the valves are really worn. good Luck P.S. My 94 Civic still runs like new and get great MPG. So if you get good MPG and have decent power, you don't need valve adjustment.

- Q:recently changed head gasket. could valves tap from the push rods being mixed up? they all seemed to be the same size and i know the other side was exactly the same when put back together but this side is mixed up. could this make the valves go crazy? and i need to replace my water pump because its getting very hot and no coolant moving. and everything is smokin up, took off oil cap and it was steaming. would that have anything to do with making the valves tap?

- When you replaced the head gasket, did you properly adjust the valves, as in preload? Doesn't sound like it...as for different length push rods, you'll have to check that repair manual you went by...you did read the repair manual, right? As for the rest, head gaskets must go on only one way. Did you make sure all the holes lined up correctly, and one or more cooling passages weren't blocked by the gasket? Torqued properly, in sequence? Were the intake manifold and exhaust gaskets installed and torqued properly? Sorry to be a nag, but as you can see there is more to it than just unbolting and rebolting parts...

- Q:Could my subs kill my EGR valve? I replaced my O2 sensor and my check engine light didn't go off. So I had it checked again and the same problem was still there. It said that all the cylinders were running either rich or lean..... I can't remember. But I was told it could be the EGR Valve so I replaced it and for about a week the check engine light was off.Now its back on. Had it checked again and the same deal was going on. Oh there was also a low voltage reading..... which is why I'm thinking its my subs.So could it be my subs that keeps killing my EGR valve? And any solutions will be helpful. I don't want to have to replace my alternator because its in an extremely tough place to reach. And I already have a small Cap.... .5. My subs handle 600 RMS total. WOuld getting a bigger Cap help?

- next time state year/make/model/mileage. most egr valves operate via vacuum. your subs can't affect a vacuum operated egr valve. if the o2 sensor didn't help out, you probably have a bad vacuum hose somewhere. that will cause the system to go into havoc because the car computer can't compensate for the excessive air being sucked in. a cap does not help with anything except for a loud THUMP. the THUMP causes a voltage spike and stresses the charging system. the cap takes care of the thump safer, it's not a complete solution.

- Q:Whilst pumping up my new tubular tyre, the head of the presta valve snapped off! Because this is a tubular tyre, I spent a lot of time (and cash) gluing it on and applying it etc, so I'm reluctant to buy a new tub. Is there any way getting a new presta valve head without replacing the whole tyre?Thanks in advance.

- By the head of the valve, do you mean the lock nut? The part you unscrew to press in to release pressure? If that is what you mean, it has happened to me several times. It is usually from the way the pump is applied or released from the valve. Hand held pumps cause it more than floor pumps. The thin screw that the nut tightens on simply snapped. It can even happen on a presta inner tube. You can just inflate and ride with the nut broken off. Shouldn't be a problem. If it is like any tubular I have used the valve core is replaceable. This is because tubs come with one length valve and for dish wheels you need to install an extension. Ask your bike shop if you don't know or look up the manufacturer's site for the brand tub you have. They usually say if it has a removable valve. If they don't come out and specify if the valve is removable or not, if they sell extensions for their tires it is replaceable. The extensions are supplied with a little tool to remove and tighten the valve. Simple pliers can be used if you are careful not to squeeze the valve too tight.

- Q:I have a suzuki bandit 1200 (2001) and I think it needs a valve adjustment. The engine is tapping at idle and while riding but I cant stop riding long enough to get it fixed. All the shops I checked with are booked for a week. Will I make the engine worst by riding it like this?

- Drop off the tapping bandit at the shop. The adjustment will be made and presto back in business. Dont't be silly look around for an independent garage owner that will do it for $50 instead of the $200 the dealer will charge. What do you mean---can't stop riding long enough. Blow the tapping in to a big thump and you might end up hospitalized---cause it broke.

- Q:IT USUALLY TAKES 2 SECONDS TO START THE MOTOR. NOW, IT TAKES OVER 40 SECONDS AT 7 AM. IT ALMOST KILL THE BATTERY. IF YOU PARK FOR 1 HOUR, 2ND START TAKES 10 SECONDS. IS THIS HAPPENING BECAUSE THE VALVES NEEDS ADJUSTING? HOW AND WHAT IS THE EASY WAY OF VALVES TUNE-UP?

- MY MECHANIC TOLD ME: AT 9000 MILES, SCOOTER IS DUE FOR VALVE ADJUSTMENT. EVERYTHING ELSE SHOULD BE OK. 1] WAIT UNTIL MOTOR COOLS OFF 2] REMOVE PLASTIC VALVE COVER 3] LOOSEN RIGHT FENDER TO GET EASY ACCESS TO VALVES 4] USE 8 MM SOCKET TO TAKE OFF THE FOUR VALVE COVER SCREWS 5] USE 10 MM SOCKET TO TAKE OFF THE LAST TWO NUTS 6] REMOVE ALUMINUM VALVE COVER 7] PISTON MUST BE FIRST COME ALL THE WAY UP BEFORE ADJUSTING VALVES 8] CHAIN AND DISK HAS 3 HOLES, SET HOLE ONE UP, HOLE TWO DOWN, AND HOLE THREE TO THE LEFT [ IN THE MIDDLE BETWEEN THE TWO VALVES. 9] MUST HAVE A GAGE FEELER SIZE 3/1000, AND 4/1000 $7 SET AT ADVANCE AUTO 10] USE 9 MM SOCKET TO LOOSEN THE TOP INTAKE VALVE NUT USE GAGE SIZE 3/1000 ON TOP OF VALVE. ADJUST VALVE SCREW, NOT TOO TIGHT, AND NOT TOO LOOSE HOLD THE TOP SCREW WITH A PLIER WHILE TIGHTENING THE TOP NUT WITH 9 MM OPEN WRENCH. MAKE SURE THE NUT IS GOOD AND TIGHT. MINE WAS MOVED TO SIZE 7/1000 MM, THEREFORE, IT WAS HARD TO START. 11] USE 9 MM SOCKET TO LOOSEN THE BOTTOM EXHAUST VALVE NUT USE GAGE SIZE 4/1000 ON TOP OF VALVE. ADJUST VALVE SCREW, NOT TOO TIGHT, AND NOT TOO LOOSE HOLD THE TOP SCREW WITH A PLIER WHILE TIGHTENING THE TOP NUT WITH 9 MM OPEN WRENCH. MAKE SURE THE NUT IS GOOD AND TIGHT. MINE WAS MOVED TO SIZE 2/1000, IT WAS HARD TO START. 12] HOOK THE GROUND WIRE, AN CHECK IF IT IS EASY TO START 13] ONCE IT HAS GOOD START, PUT THINGS BACK IN REVERSE AS THEY WERE. 14] FIRST PUT COVER AND ALL SCREWS HAND TIGHT ONLY, THEN TIGHT THEM GOOD. I STARED TIGHTENING THEM ONE AT A TIME, THEN THE LAST ONE WOULD NOT FIT I HAD TO LOOSEN ALL OF THEM AND GET THEM ALL STARTED AND HAND TIGHT FIRST. 15] ADVANCE AUTO MAY LET YOU USE SOME LOANER TOOLS 16] PUT EVERYTHING BACK TOGETHER AND YOU READY TO GO FOR 5000 MILES. GOOD LUCK, WERE YOUR HELMET, AND DRIVE CAREFUL. TRY NOT TO DRIVE IN BAD WEATHER WEATHER LINK: www.spc.noaa /

- Q:.The valve behind the toilet is spewing water (we have connected a hose to it and have it emptying into the tub). When we try to shut the water off from that valve, the knob or turny-thingy (the name escapes me right now) just turns and turns correcting the water flow slightly, but not shutting it off.The problem it that we can't find the main water valve outside the house. What am I looking for please?!? Also, we shut a valve off in the garage, but it was for the hot water.Help!

- You can shut it off from there and if you feel confident with your plumbing abilities, take apart your valve take all those parts to the hardware store. I highly suggest either a mom pop hardware store or a local plumbing supply over a big box like Lowes or HD. The big box employees are NOT plumbing experts. I had the same issue with my valve when I bought my place I swapped out what I needed have never had a drip since then.

- Q:Describe a typical semilunar valve and tell how it works

- The semilunar valves are located between the aorta and the left ventricle and between the pulmonary artery and the right ventricle.(aortic valve and pulmonary valve) The semilunar valves are flaps of endocardium and connective tissue reinforced by fibers which prevent the valves from turning inside out. They are shaped like a half moon, hence the name semilunar (semi-, -lunar). they prevent the back flow of blood to left and right ventricles respectively.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Swing Check Valve Wafer Type Double PN 16 Mpa

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords