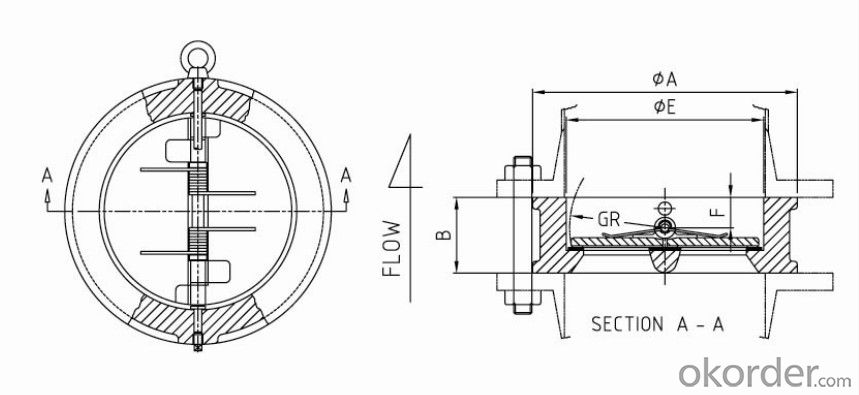

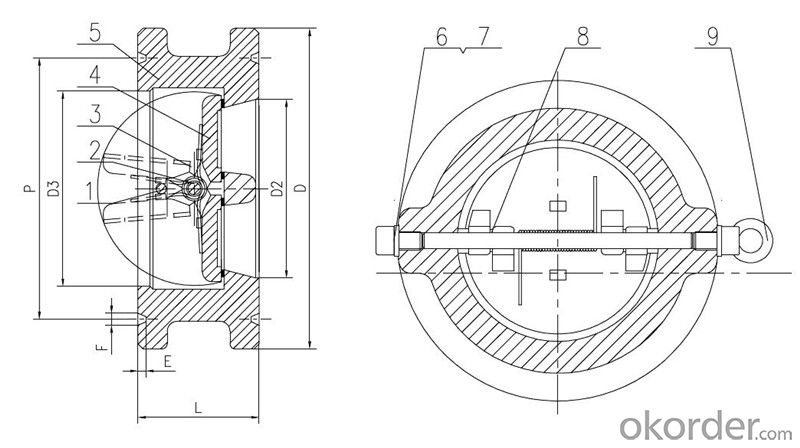

Swing Check Valve Wafer Type Double Disc DN 450 mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Products Description of Swing Check Valve

Check valves are used in pipes under pressures between PN1.6~16.0MPa(Class150~2500Lb), working temperatures-196~600℃, They are used in industries include oil, chemistry, pharmaceutical, fertilizer, and power gene-ration to prevent the backward flux of the media.

The main structure features of Swing Check Valve:

1、The products feature a reasonable structure, reliable seal, good performance and nice modeling.

2、Either soft or hard seal can be selected for the product upon different working conditions.The sealing face is built up with Co-based

carbide alloy, leaving a better wearability, corrosion and scrap resistance and a longer duration.

3、Small opening pressure, the disc can be opened fully with a very small pressure differential.

4、Inside-set bolt-bearing structure reduces leakage and reliable use.

5、PN≥16.0Mpa (class1500), the middle cavity uses a self-tightening sealing structure to have the sealing performance reinforced along

with the pressure rise so as to ensure the sealing performance.

6、Different parts materials and different sizes for flange, butt-welding are available for sensible combination according to different working facts and customers' requirements.

Parameter of Swing Check Valve:

Standard Criteria | GB customize |

Pressure Rating | 1 Mpa 1.6 Mpa 2.5 Mpa 4 Mpa 6.4 Mpa 10 Mpa 16 Mpa customize |

Valve Size | 50 mm 65 mm 80 mm 100 mm 125 mm 150 mm 200 mm 250 mm 300 mm 350 mm 400 mm 450 mm 500 mm 600 mm customi |

Actuator | Automatic customize |

Connection | Wafer customize |

Medium | Oil Steam Water customize |

Medium Temperature | -196~600℃ customize |

Structural style | Swing double-clack structure customize |

Application Fields | Agriculture Electricity Medical Petrochemical customize |

1-Body Material | CF3 CF8C CF8 WCB CF8M CF3M customize |

2-Disc | CF3 CF3M WCB CF8 CF8M CF8C customize |

3-Pivot | 1Cr13 1Cr18Ni9Ti 0Cr18Ni12Mo2Ti 2Cr13 customize |

4-Spring | 60Si2Mn 1Cr18Ni9Ti 4Cr13 0Cr18Ni12Mo2Ti customize |

Design Standard | GB/T 12224 customize |

Connection Standard | GB/T 9113 HG 20592 JB/T 79 customize |

Test Standard | JB/T 9092-1999 customize |

Face to Face | GB/T 15188.2-1994 customize |

Images of Swing Check Valve:

FAQ of Swing Check Valve:

Q1:I can’t find the type of steel check valve which I need. what can I do?

The chart above only lists out some common composition of steel check valve parts.We may provide other different parts material composition according to the customer's request or the actual valve working condition.

Q2:Which certification do your products pass?

Our products are in accordance with ISO 9001、ISO 14001、API 6A、API 6D、TS CE、API607/6FA/BS6755.

Q3:How can I place an order?

The only one thing you should do is to tell us the sepecification about type 、quantity and mode of transportation, then we will send you quotation within 24 hours.

- Q:had a water heater put in after that i have low hot water pressure it get hot but goes to a low stream.when i try to adjust gate valve it keeps turning

- freeze the line coming to the valve, with a co2 fire extinguisher, or dry ice, then swap the valve, and let it thaw

- Q:The atrioventricular valves will be open whenA. Atria are in diastole and ventricles are in systole B. Pressure in the ventricles is greater than the pressure in the great arteries C. The ventricles are being passively filled D. The ventricles are in isovolumetric contraction

- Answer: (c) The ventricles are being passively filled. During diastole, a normally-functioning mitral valve opens as a result of increased pressure from the left atrium as it fills with blood (preloading). As atrial pressure increases above that of the left ventricle, the mitral valve opens. Opening facilitates the passive flow of blood into the left ventricle. Diastole ends with atrial contraction, which ejects the final 20% of blood that is transferred from the left atrium to the left ventricle. This amount of blood is known as end diastolic volume (EDV), and the mitral valve closes at the end of atrial contraction to prevent a reversal of blood flow. Mitral valve also opens when right ventricle is passively filled.

- Q:I have a 03 civic ex with 96k how important is it that I do a valve adjustment. The engine runs smooth.

- the factory maintenance manual calls for the valves to be checked and adjusted if necessary every 110,000. unless they're noisy (loud tapping) they probably don't require adjustment. The older Civics were very sensitive to the valve adjustment but the 2003 won't give you any problems if the valves aren't noisy. that being said, if you notice a decrease in performance or fuel economy around that mileage it won't hurt to get them checked and adjusted. hope that helps

- Q:My sprinkler valve I just put in leaks from the top knobs you turn to allow water to pass through to the 3 main pvc pipes. I turn the water on on the main water line, open the little black twisty knobs to allow the water to pass through to the irrigation lines, but water leaks out through all 3 black twisty knobs. What do I need to do?!?!?!

- You are turning on electric valves, manually, with the bleeder valve (little black twisty thing). It is normal for this to happen. This valve can turn on and off a zone, but it also releases air from within the lines causing water to spit out with it. After the air is out, you can twist it down enough to stop the leak and still have that zone remain on.

- Q:Where can I get a trigger valve like a one you use on a propane tank.

- Its okorder

- Q:I was wondering if anyone knew how important tire valve stem caps were in maintaining inflation pressure in auto tires? I noticed one of my tires losing air slowly (from 30 psi to 21 psi in about a week) and this tire (unlike the other three) also had a missing tire valve stem cap. I've just replaced it, and was wondering if a missing valve stem cap caused faster loss of tire pressure.

- The valve caps main purpose is o keep dirt/debris out of the valve stem. if the valve inside were to leak due to not being tight or dirt holding it open the cap may prevent leaks. but if you refill that tire once a week, the dirt would have been forced in. replace the cap and see what happens. check the tire and valve stem with soapy water to help find the leak.

- Q:If I flush the toilet the drama begins. While the toilet is flushing, if I lift the lift of the lid of the tank cover NOT THE SEAT, water shoots up straight in the air from the top/cap of the fill valve. This is a picture of a toilet fill valve.

- The okorder . Type in toilet fill valve in the search box and click on SEARCH. You will see a list of How-To videos that will help you with this project.

- Q:Water has been seeping out of the sprinklers closest to the anti-siphon valve. Water seeps out of the sprinkler even when the anti-siphon valve is manually closed and not connected electronically. I opened up the anti-siphon valve to inspect the diaphragm, but there is no debris nor it was damaged. To be sure, I switched the diaphragm chamber of the two anti-siphon valves (a suspected leaky one and another good working one), but leak persists from the same sprinklers. I think the leak is from the (float?) rubber seal at the bottom of the stem closing the inlet valve. My anti-siphon is a Hardie (or Irritrol) model 311A series.1) Is my troubleshooting and logic correct? What other components could have contributed to the leak described? 2) At what scenario will water be flowing out of the anti-siphon cap?3) How can I determine if my anti-siphon valve has a vacuum breaker? What is a vacuum breaker good for?4)Which brand makes the most reliable anti-siphon valve?

- Sprinkler Anti Siphon Valve Leaking

- Q:What is the International Standard or other acceptable calculation or table for determine the air supply of pneumatic actuator in shutdown valve 6 to 24.Desired answer will be air flow in SCFM.Thank you.

- Shut down valves I've worked with haven't had an 'Air Flow' for their operation. For the smaller valves, they consist of diaphragm operated valves either held open or closed by pneumatic pressure. The air supply at 25psi to give a diaphragm holding pressure of 15 psi, is via a solenoid valve which dumps the air pressure to either open or close the valve depending upon its function. (That of isolating a system or relieving pressure). The solenoid is actuated by a signal from the shut-down system, and the valve is a 3-way unit which isolates the supply air and vents the pressure off the diaphragm. Other SDV's in my experience, are operated in a similar way but are much larger and are operated by a pneumatic air cylinder and piston with air supplied at 100 psi. Others encountered are ... MOV's...Motor Operated Valves that can be automatically operated from the shutdown system, or Operated Remotely from a safe distance (ROV's).

- Q:My boyfriend is getting mitral valve replacement surgery soon, he is getting a mechanical valve put in.Has anyone had this surgery done? What are the risks. Anything else need to know about this surgery that is important. Im just worried about the surgery wanting to know as much as I can to be prepared. thank you

- Haven't had it done before but: It's a pretty involved procedure. Patient is put under general anesthesia and is usually on the cardiopulmonary bypass machine (heart-lung machine) since you can't really replace a heart valve if the heart is beating. mortality for full valve replacement according to wiki is 6-8 percent, prob less than 5% for young healthy patients. Recently, many people have been doing the procedure laparoscopically. Patients are put into the surgical ICU for typically 1-2 days after the surgery. You can be discharged about a week after. Obviously there's risks, this is a very involved and definitely not a simple procedure. However, the cardiothoracic surgeons do these procedures every day for their entire lives-they're very skilled and qualified. good luck!

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Swing Check Valve Wafer Type Double Disc DN 450 mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords