Swing Check Valve Wafer Type Double Disc DN 100 mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Products Description of Swing Check Valve

Check valves are used in pipes under pressures between PN1.6~16.0MPa(Class150~2500Lb), working temperatures-196~600℃, They are used in industries include oil, chemistry, pharmaceutical, fertilizer, and power gene-ration to prevent the backward flux of the media.

The main structure features of Swing Check Valve:

1、The products feature a reasonable structure, reliable seal, good performance and nice modeling.

2、Either soft or hard seal can be selected for the product upon different working conditions.The sealing face is built up with Co-based

carbide alloy, leaving a better wearability, corrosion and scrap resistance and a longer duration.

3、Small opening pressure, the disc can be opened fully with a very small pressure differential.

4、Inside-set bolt-bearing structure reduces leakage and reliable use.

5、PN≥16.0Mpa (class1500), the middle cavity uses a self-tightening sealing structure to have the sealing performance reinforced along

with the pressure rise so as to ensure the sealing performance.

6、Different parts materials and different sizes for flange, butt-welding are available for sensible combination according to different working facts and customers' requirements.

Parameter of Swing Check Valve:

Standard Criteria | GB customize |

Pressure Rating | 1 Mpa 1.6 Mpa 2.5 Mpa 4 Mpa 6.4 Mpa 10 Mpa 16 Mpa customize |

Valve Size | 50 mm 65 mm 80 mm 100 mm 125 mm 150 mm 200 mm 250 mm 300 mm 350 mm 400 mm 450 mm 500 mm 600 mm customi |

Actuator | Automatic customize |

Connection | Wafer customize |

Medium | Oil Steam Water customize |

Medium Temperature | -196~600℃ customize |

Structural style | Swing double-clack structure customize |

Application Fields | Agriculture Electricity Medical Petrochemical customize |

1-Body Material | CF3 CF8C CF8 WCB CF8M CF3M customize |

2-Disc | CF3 CF3M WCB CF8 CF8M CF8C customize |

3-Pivot | 1Cr13 1Cr18Ni9Ti 0Cr18Ni12Mo2Ti 2Cr13 customize |

4-Spring | 60Si2Mn 1Cr18Ni9Ti 4Cr13 0Cr18Ni12Mo2Ti customize |

Design Standard | GB/T 12224 customize |

Connection Standard | GB/T 9113 HG 20592 JB/T 79 customize |

Test Standard | JB/T 9092-1999 customize |

Face to Face | GB/T 15188.2-1994 customize |

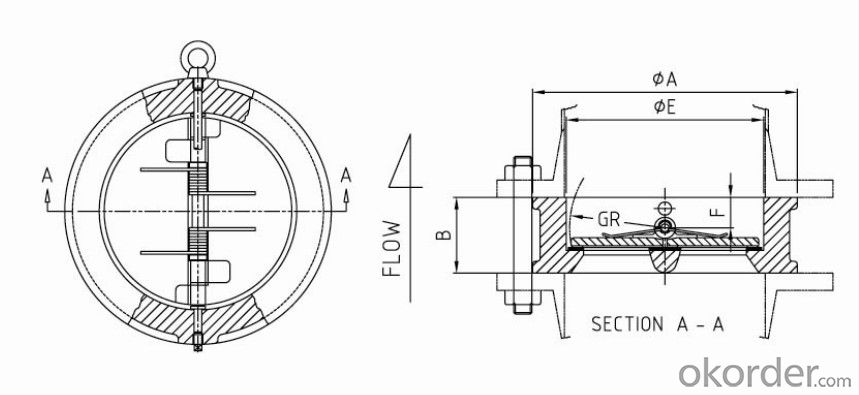

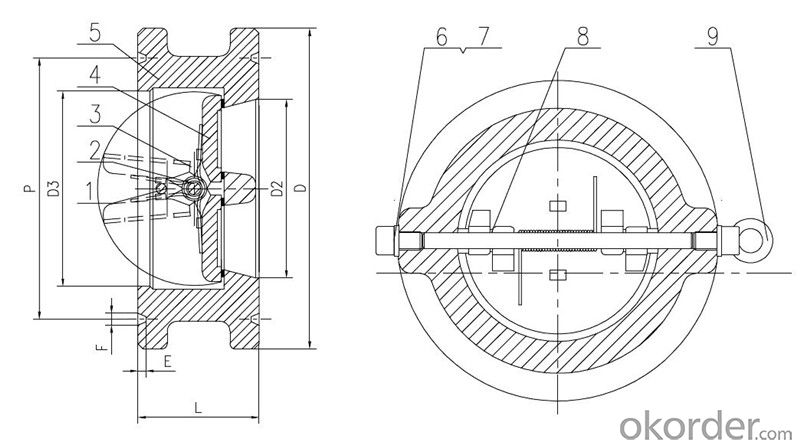

Images of Swing Check Valve:

FAQ of Swing Check Valve:

Q1:I can’t find the type of steel check valve which I need. what can I do?

The chart above only lists out some common composition of steel check valve parts.We may provide other different parts material composition according to the customer's request or the actual valve working condition.

Q2:Which certification do your products pass?

Our products are in accordance with ISO 9001、ISO 14001、API 6A、API 6D、TS CE、API607/6FA/BS6755.

Q3:How can I place an order?

The only one thing you should do is to tell us the sepecification about type 、quantity and mode of transportation, then we will send you quotation within 24 hours.

- Q:I recently converted my furnace from l.p. gas to natural gas. It's been maybe two weeks of me troubleshooting and replacing. I have a new gas valve and transformer in the furnace. There is 24v running to the valve and it clicks to open but no gas comes out. I have exhausted all my options with the mechanical/electrical components on the furnace. I have bled the valve to be sure that there was gas making it to the inlet side. Does anyone have an idea as to why the valve stopped opening once I converted it over?

- may sound like a stupid answer but there is an arrow on the bottom of the gas valve and i have seen them put in backwards,or it sez inlet on 1 end,,make sure the knob is turned to on,make sure the arrow is pointing towards the burners

- Q:1994 Chevy K1500 P/U 5.7 liter 350 4X4 5 speed. When the truck is under a hard pull the valves start knocking, the knock sensor adjust the timing and the check engine light comes on. The code for the light is not detecting knock sensor. I have changed the pcv valve (which was suggested) and no change. This has went on for about 5 years. Doesn't matter the grade of fuel I use. Routine maintance and tune ups have been done to this truck. The converter was taken off 7 years ago because it was clogged. The truck runs rich after the timing adjust. The light resets itself when it is turned off. ( the code is saved)

- Excessive carbon build up on the valves may also be causing pre-detonation which the knock sensor will not be able to correct. If it is a high mileage or a rough service motor it may be time to open it up and see if it's time for a valve job, or possibly a rebuild.

- Q:My cardiologist says I have Mitral Valve Relapse. She says MVR is when there is a backflow of bood entering the heart. When I checked online for MVR, I couldn't find anything except MVP (Mitral Valve Prolapse). What is MVR and how is it different than MVP?

- I believe you DO mean MVP. You probably misunderstood your cardiologist. Prolapse is a deformation of the valve in which valve does not completely close, causing a back flow of blood into the atrium. In most cases this is relatively benign and in fact, occurs in about 10% of people. In severe cases, you may need a value replacement, but usually this occurs at birth or after a disease damages the heart.

- Q:are the carborator reed valves supposed to be open or closed on a 1999 yz 250?dirt bike

- the aggregate is slightly skinny. The exhaust will smoke much less, however the appropriate end will ware quicker then standard. replace the piston rings as quickly as a 12 months could shop the engine risk-free.

- Q:We have an oil steam system. There are Dole valves - 1A on each of the radiators. We bought new ones. They don't seem to be working. They look like a bullet shape with a screw in (on the side of the bullet) to the radiator. On the top of the bullet is a slit with numbers 1-10 on a dial. A picture we saw on the web showed a plastic piece of tubing in the screw part which looks like it goes into the radiator. If we remove the valve, the radiator gets hot with steam coming out of the hole. With the new valve on, the radiator barely gets warm. We're in Piscataway, NJ 08854. H-E-L-P.

- Seems to me that a steam valve would need to hold a lot more pressure than a hot water valve. Steam is a high pressure gas and water is a liquid irregardless how hot it is (below boiling point) I am not a qualified plumber or boiler tech but personally I wouldn't use a steam valve for water or vise versa.

- Q:Pressure relief valve on boiler is dripping.Starts to drip more when the boiler is turned on.Bad relief valve?

- Check The Pressure Gauge Should Be Between 12 to 15 Psi. If it's above That Could be Expansion Tank could be overfilled. Or Feeder .

- Q:How much would it cost to get a new valve cover gasket on a 1993 Nissan Quest van?? I know of a van for sale, but they said it might need a gasket soon. How much plus labor, average, do you think it'll cost? Thanks!!

- The valve cover gasket (parts and labor) is about $100 - $200 for the left side and $300 - $400 for the right hand side, but be sure you didn't misunderstand and the failing gasket is actually a head gasket. Those are a big deal: $1500 - $2000.

- Q:When I went to cardiologist he said i had normal EKG, excellent blood work high HDl 58, low triglycerides only 51, and LDL was like 71, ejection fraction of 65% he said I was fine but he said I had mild mitral valve prolapse. DO I have to worry abt the mitral valve prolapse? Im healthy and can I live a normal long life any opinions?I dont smoke, dont do drugs, no family history of Heart problems just some cholesterol but mine is low so Im good

- In 95 plus percent of cases so-called mitral valve prolapse is a normal variant. If yours was other than a normal variant your cardiologist should have discussed this with you. As such I would not worry. JR

- Q:I have a 98 Mitsubishi Mirage, seems there is a valve cover oil leak, i know this can be easily fixed by replacing the gasket.. but how will i know if the leak isn't from the valve cover gasket . Is the cylinder head gasket a major issue also .. if its not really the valve cover thats producing the oil leak should i not worry and just replace the valve cover gasket .?

- The valve cover gasket is not as big of a deal, if it gets really bad you will just start smelling a lot of burining oil. The head gasket can become a major issue, especially since coolant also flows through more internal part of the gasket. The question you need to ask is if the leak is closer to the top (valve cover) or farther down the block?

- Q:I need to make a ball valve that will open with no manual force but by a motor of some sort to spin it and release water. how do i make a ball valve controlled by preferably a motor or other CHEAP device. I need to do this for less that 20$

- put a slave servo on it,

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Swing Check Valve Wafer Type Double Disc DN 100 mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords