Swing Check Valve Wafer Type Double Disc Body Material CF8C

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

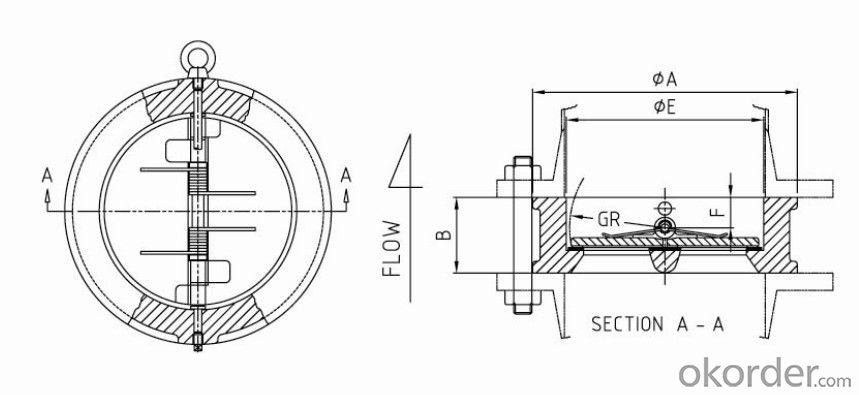

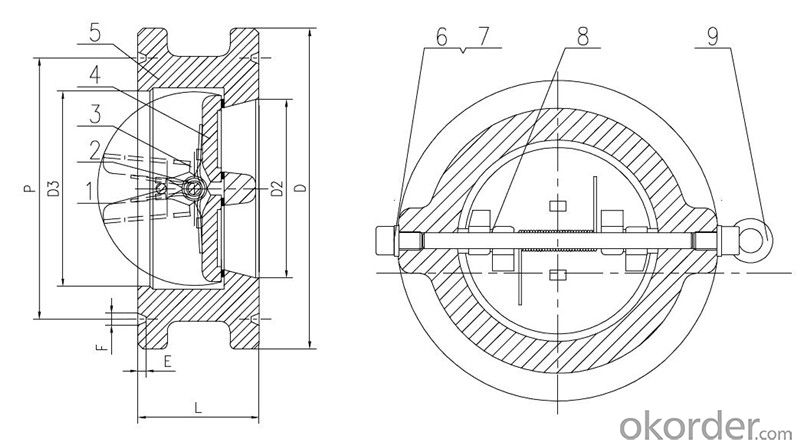

Products Description of Swing Check Valve

Check valves are used in pipes under pressures between PN1.6~16.0MPa(Class150~2500Lb), working temperatures-196~600℃, They are used in industries include oil, chemistry, pharmaceutical, fertilizer, and power gene-ration to prevent the backward flux of the media.

The main structure features of Swing Check Valve:

1、The products feature a reasonable structure, reliable seal, good performance and nice modeling.

2、Either soft or hard seal can be selected for the product upon different working conditions.The sealing face is built up with Co-based

carbide alloy, leaving a better wearability, corrosion and scrap resistance and a longer duration.

3、Small opening pressure, the disc can be opened fully with a very small pressure differential.

4、Inside-set bolt-bearing structure reduces leakage and reliable use.

5、PN≥16.0Mpa (class1500), the middle cavity uses a self-tightening sealing structure to have the sealing performance reinforced along

with the pressure rise so as to ensure the sealing performance.

6、Different parts materials and different sizes for flange, butt-welding are available for sensible combination according to different working facts and customers' requirements.

Parameter of Swing Check Valve:

Standard Criteria | GB customize |

Pressure Rating | 1 Mpa 1.6 Mpa 2.5 Mpa 4 Mpa 6.4 Mpa 10 Mpa 16 Mpa customize |

Valve Size | 50 mm 65 mm 80 mm 100 mm 125 mm 150 mm 200 mm 250 mm 300 mm 350 mm 400 mm 450 mm 500 mm 600 mm customi |

Actuator | Automatic customize |

Connection | Wafer customize |

Medium | Oil Steam Water customize |

Medium Temperature | -196~600℃ customize |

Structural style | Swing double-clack structure customize |

Application Fields | Agriculture Electricity Medical Petrochemical customize |

1-Body Material | CF3 CF8C CF8 WCB CF8M CF3M customize |

2-Disc | CF3 CF3M WCB CF8 CF8M CF8C customize |

3-Pivot | 1Cr13 1Cr18Ni9Ti 0Cr18Ni12Mo2Ti 2Cr13 customize |

4-Spring | 60Si2Mn 1Cr18Ni9Ti 4Cr13 0Cr18Ni12Mo2Ti customize |

Design Standard | GB/T 12224 customize |

Connection Standard | GB/T 9113 HG 20592 JB/T 79 customize |

Test Standard | JB/T 9092-1999 customize |

Face to Face | GB/T 15188.2-1994 customize |

Images of Swing Check Valve:

FAQ of Swing Check Valve:

Q1:I can’t find the type of steel check valve which I need. what can I do?

The chart above only lists out some common composition of steel check valve parts.We may provide other different parts material composition according to the customer's request or the actual valve working condition.

Q2:Which certification do your products pass?

Our products are in accordance with ISO 9001、ISO 14001、API 6A、API 6D、TS CE、API607/6FA/BS6755.

Q3:How can I place an order?

The only one thing you should do is to tell us the sepecification about type 、quantity and mode of transportation, then we will send you quotation within 24 hours.

- Q:what do the doctors do and is it dangerouse? aslo how do you get a cloged valve?

- Are you referring to heart valves? They don't really get clogged, but can get calcified and what we call stenotic (the area through which blood flows is reduced). There are ways to manage valvular heart disease with medications, but some people require surgery and valve replacement. There are mechanical and biologic heart valves that can be put in place of a damaged valve. The surgery is one of the riskier ones, because it's on the heart.

- Q:If I buy one of those Presta valve adapters can I just screw it on and leave it on while I ride? Will I lose air pressure at to fast of a rate?

- If ya want to leave an adaptor on you could. I would close the valve though. That way you would have the adaptor always available. It only takes a few seconds to open the valve to fill the tire. Or, like most people, simply buy a punp that fits presta.

- Q:Hey my sexy internet homies lt;3: I need help on artificial valves. I need to know the following things:How do the properties of the materials artifical heart valves are made from make them useful?Explain how the structure of the technology is related to the function that it needs to perform.Thanks!!

- There are three of these things: the caged-ball which utilizes a metal cage to house a metal ball, tilting-disc valves, which have a single circular occluder controlled by a metal strut. They are made of a metal ring covered by a tissue, into which the suture threads are stitched, in order to keep the valve in place once implanted and there's bileaflet valves, which consist of two semicircular leaflets that rotate about struts attached to the valve housing which is the most recent type, eh? So heart valves are considered to be extremely durable. They're made of either pyrolytic carbon or titanium coated with pyrolytic carbon, and the sewing ring cuff is Teflon or polyester or dracon (probably dacron :P). They key to the materials chosen is durability because of the constant fluid flow. I see this as pure engineering, not medicine, specifically fluid mechanics: like if there are rare complications for example thrombus formation is a debilitating side effect of high shear stresses created by design of the valves. Ideal heart valve from an engineering view would produce minimal pressure drops of course have small regurgitation volumes because it's supposed to minimize turbulence and regulate the flow.

- Q:I got a french horn, but don't know if I can just use the valve oil I use for my trumpet. please help, thnx in advance :D

- Simply said: nope

- Q:I was diagnosed with Mitral Valve Prolapse. Does anyone else have this? Does this cause panic attacks? I have heard that. What other problems does it cause?

- My 8 yr. old son was thought to have this at birth, thankfully he out grew it It can cause your heart to beat rapidly, especially during physical activity. There are different types also, but mainly a valve in your heart is not formed correctly causing it not to seal witch creates the back flow of blood. Look up MVP on the web and you can find tons of info. on it! Also, make sure to have a sonogram and speak to a great cardiologist!

- Q:So i was looking for car parts and i was using my favorite website, and i was looking at turbos which are wicked costly. But i saw some blow off valves which i have heard about before. But i was wondering if you need a turbo in order to have a blow off valve installed into your car. And if you don't my next question would be is it hard to put one in and how?? Thank you for your time..

- A blowoff valve goes onto your intake or the piping from your turbocharger to make sure that you dont run to much pressure they are adjustable to whatever pressure you desire. Usually people running a positive displacement blower or a turbochargers run them. That being said I'm sure that you could put one on your car but without a power adder it would never blow off. Except in the case of a intake manifold overpressure such as a backfire.

- Q:here are pix's i want to no, if there is a easy fix or does it have 2 b machined thanksi think it use to have a bent valve in it

- hard to tell looking at your pic,s. your best bet is to find a trust worthy machine shop...they can tell you if they can be lapped or if they need replacing...newer heads have hardened valve,s seat,s..if damaged they should be replaced ...valve,s , seat,s , guide,s , valve seal,s , possible rocker assembly,s , lifter,s , push rod,s ,Etc......best of luck!

- Q:and i want to but over size valve seatscan i do it in a 1991 chevy chenynne k2500

- Jasons $1500 quote is way over priced. Valve seats crack due to heat and age. Its a common prob with chevy heads really. Price at a machine shop to replace the seats and do a valve job will be about $400 If your wanting to go larger on the valves, then you will need new valves ($75-150) Now why do you want larger valves in a stock head? Most chevy heads has 1.84 or 1.94 intake and 1.50 exhaust valves. I had 1.94/1.50's on my 355 making 505 HP, and running mid 11's 1/4 mile in a camaro. I have now stepped up to 2.02/1.60 It might be cheaper and better for you to buy an aftermarket set of heads with the larger valves if thats what you want. Aftermarket heads range from about $600 to 1200 a pair. I bought a new bare set of alum brodix IK 200cc heads for under $700, then bought all parts I needed to build them with for about $175

- Q:I am a junior piping engineer. I want to know what is the meaning of term Triple Eccentric in Triple Eccentric Butterfly ValveButterfly Valve. So kindly enlighten me.

- Above answers your question. I've used these and they work great. But they cost much more then your tradition quarter turn butterfly valve.

- Q:So i finaly got my check valve and my airstone. The airstone is actually a flat round airstone and is 5 inches in diameter to be in my 10gallon. Is it to big? though i have a tetra whisper air pump for 10-30g.And how do i place the check valve? Do i put it closer to the tank or closer to the pump? (just to make sure since i heard so many different ways people put it). Or does it even matter?And lastly, do i put the OUT side of the check valve facing towards the tank or the pump?Thanks! after this im ready to install it!

- Adequate the purpose you let a tank cycle in the first place is due to the fact of Bactria needs to grow that will maintain your water clear. As for overstocked. I consider your proper on the threshold of being over stocked. Just preserve the tank walking a lil longer and spot if it clears up. But when your 15 gallon tank has the filter from the ten gallon tank that could be why to you dont have sufficient water moving around to scrub it

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Swing Check Valve Wafer Type Double Disc Body Material CF8C

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords