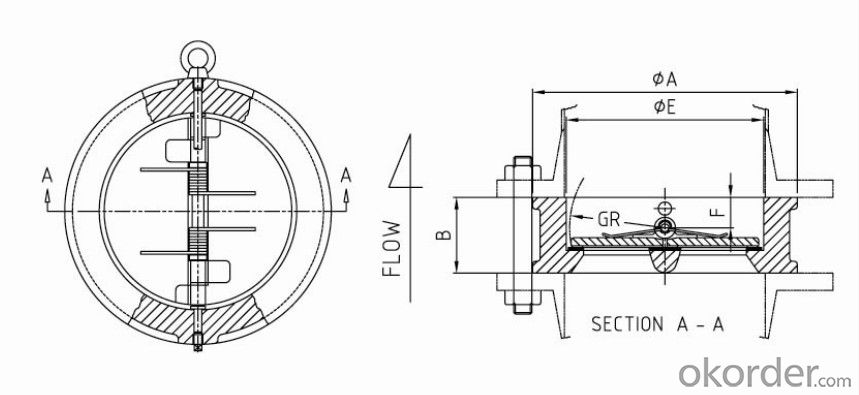

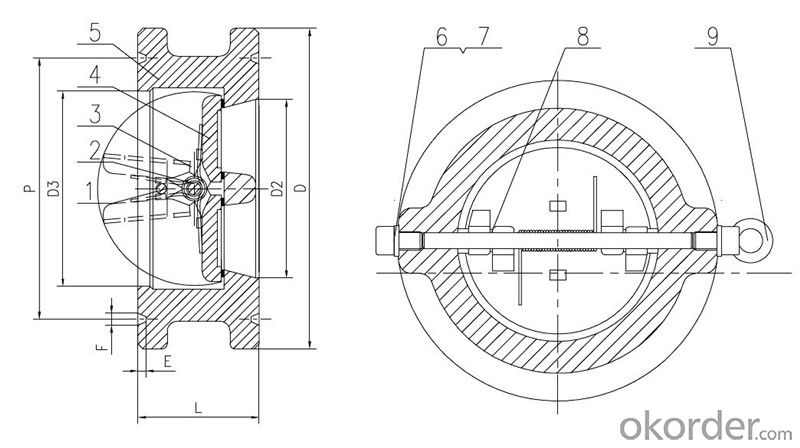

Swing Check Valve Wafer Type Double Disc Body Material CF3

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Products Description of Swing Check Valve

Check valves are used in pipes under pressures between PN1.6~16.0MPa(Class150~2500Lb), working temperatures-196~600℃, They are used in industries include oil, chemistry, pharmaceutical, fertilizer, and power gene-ration to prevent the backward flux of the media.

The main structure features of Swing Check Valve:

1、The products feature a reasonable structure, reliable seal, good performance and nice modeling.

2、Either soft or hard seal can be selected for the product upon different working conditions.The sealing face is built up with Co-based

carbide alloy, leaving a better wearability, corrosion and scrap resistance and a longer duration.

3、Small opening pressure, the disc can be opened fully with a very small pressure differential.

4、Inside-set bolt-bearing structure reduces leakage and reliable use.

5、PN≥16.0Mpa (class1500), the middle cavity uses a self-tightening sealing structure to have the sealing performance reinforced along

with the pressure rise so as to ensure the sealing performance.

6、Different parts materials and different sizes for flange, butt-welding are available for sensible combination according to different working facts and customers' requirements.

Parameter of Swing Check Valve:

Standard Criteria | GB customize |

Pressure Rating | 1 Mpa 1.6 Mpa 2.5 Mpa 4 Mpa 6.4 Mpa 10 Mpa 16 Mpa customize |

Valve Size | 50 mm 65 mm 80 mm 100 mm 125 mm 150 mm 200 mm 250 mm 300 mm 350 mm 400 mm 450 mm 500 mm 600 mm customi |

Actuator | Automatic customize |

Connection | Wafer customize |

Medium | Oil Steam Water customize |

Medium Temperature | -196~600℃ customize |

Structural style | Swing double-clack structure customize |

Application Fields | Agriculture Electricity Medical Petrochemical customize |

1-Body Material | CF3 CF8C CF8 WCB CF8M CF3M customize |

2-Disc | CF3 CF3M WCB CF8 CF8M CF8C customize |

3-Pivot | 1Cr13 1Cr18Ni9Ti 0Cr18Ni12Mo2Ti 2Cr13 customize |

4-Spring | 60Si2Mn 1Cr18Ni9Ti 4Cr13 0Cr18Ni12Mo2Ti customize |

Design Standard | GB/T 12224 customize |

Connection Standard | GB/T 9113 HG 20592 JB/T 79 customize |

Test Standard | JB/T 9092-1999 customize |

Face to Face | GB/T 15188.2-1994 customize |

Images of Swing Check Valve:

FAQ of Swing Check Valve:

Q1:I can’t find the type of steel check valve which I need. what can I do?

The chart above only lists out some common composition of steel check valve parts.We may provide other different parts material composition according to the customer's request or the actual valve working condition.

Q2:Which certification do your products pass?

Our products are in accordance with ISO 9001、ISO 14001、API 6A、API 6D、TS CE、API607/6FA/BS6755.

Q3:How can I place an order?

The only one thing you should do is to tell us the sepecification about type 、quantity and mode of transportation, then we will send you quotation within 24 hours.

- Q:My cardiologist says I have Mitral Valve Relapse. She says MVR is when there is a backflow of bood entering the heart. When I checked online for MVR, I couldn't find anything except MVP (Mitral Valve Prolapse). What is MVR and how is it different than MVP?

- Mitral okorder /

- Q:My 10 year old boy was diagnosed with a leaking heart valve yesterday.The Doctor is trying to get him in to see a specialist asap.She didn't seem that concerned with it,but I don't know if she was just trying to keep us calm about it.How serious is this,and is surgery the only way to fix it,or do they have meds for this condition.

- I was also diagnosed with a leaky Aortic valve at 10 years old. Mine wasnt really bad at the time, i am now 16 years old and still havent had surgery for it(surgery is really the only way to fix it, they may put him on meds also though) Your Son should be fine, i had no restrictions do to this heart problem, i lived a normal life but the best thing is to have him see a cardiologist to see how severe it is. Best of luck to you and your son

- Q:Hi guys, Thanks for your advice. RandyK is right, my dad's GP told me that if we don't get the valve operation, his heart will swell in years time and might cause more complicated illness. Just let you know my dad had seen his cardiologists recently and had some scan or tests done. The results will be discuss in next appointment, they suggested that mechanical valve would be used if the operation go ahead. At the mean time I just hope and pray his condition will under control by medication. Wendy, may I ask you how old are you when you had your valve operation? I am too scare to suggest or encourage my dad to do the operation. Because if there is any difficulties or worse ...during operation, I will be the one send him away......If anyone have a relative like my dad's case,(76 years old had valve operation) please give me some advice.. Many thanks

- Hi David, just saw your post. I was young when I had my valve replaced. I was 37, now am 42. My mother had her valve replaced at the age of 54. Honestly, that is the oldest person I know of that has had valve replacement. As with any surgery, there are alot of risks young or old. The older a person is though it may be tougher especially if he has a lot of other health problems. Just take all of this into consideration when you and your father are discussing all the details, etc. and find out any and all options that he has before proceeding with surgery. Best wishes to you both.

- Q:Hi! I have three brass gate valves surrounding a filter for my well. They are starting to show some signs of leaking. I realize that I might need to replace them... or, there seems to be a couple of places where they could be adjusted. Is this something I should do? Or, if I need to replace them, can you help me put a name to this type of valve so I can have an easier time tracking them down ?

- if its the nut with the green residue on it just give it a little tighten if they still leek you can undue the nut an wrap ptf tape (plumbers tape) round the into the space left and screw it back in make sure the bigger nut going into the body of the valve does not come loose ( roll the tape in your hand so it more rope like wrap it around or even just poke it with a small screwdriver then tighten up ) O and think it is a male to male gate valve

- Q:So it always seems that when I see the jet and foot valve out of a well there's a drop tube between the jet and foot valve. My question concerns this drop tube- is it necessary? I've got a leak somewhere, replaced the foot valve and still have a leak. I'm inclined to get rid of the old drop tube, it's crusty and likely to be the source of leaks either now or in the future. any reason to not just plumb the foot valve directly to the jet? Thank you kindly for useful information.

- This drop tube is the suction line. This tube will always be below the water level in the well. I would talk to a competent water well company and get their recommendations. Regards, Dale

- Q:i have a zone that - when turnd on by timer or manually only about 1 foot of spray comes out of sprinkler heads (used to wk fine). When i turn the ittle screw on top of valve (its about the size of a dime) water pressure comes up and wks fine - only water leaks at screw and when zone comes on next time NO pressure??? metal valves were just replaces about 1 yr ago.

- No. that's not gas tight and the plastic factors would possibly no longer delight in the petroleum ecosystem. you will choose a valve it is meant for propane. And the suitable valve would matter on the rigidity the place you meant to place in the valve interior the line. you will additionally would desire to layout the entire element very intently - no open touch relays - to steer away from a spark that would spark off errant propane.

- Q:the water coming out of the kitchen faucet has been getting weaker and weaker this week and now it flows a 3 out of 10. The thought it might be time to replace the faucet/faucet washer. I went to turn off the water under the sink.. hot and cold valve but water still comes out of the faucet with enough force aka not a dip but free flowing water. I turned the red handle valve to off as well but same thing. I am totally thrown off. HOt and cold water still comes out of faucet. When I push the faucet handle down, the water does not stop right away as well but slowly stops. No problem water into dish washer. I have replaced numerous faucets but I can not figure how water is still getting to the faucet after turning all 3 valves to shut off position. I still think it might be the faucet but now I am not sure. I am close to calling a plumber but really do not want to do that. thx

- Sounds like your water has lots of solid stuff in it. Maybe from the city, maybe from your pipes. Take the aerator off the end of the faucet and check to see if it is clogged with stuff. Be careful to note the order of the pieces that come out of the aerator--you will have to put them back. Try running faucet without an aerator. If it runs free then the stuff is your problem and is probably also the problem with the shut off. Pieces of rust or whatever on the faucet washer will allow water to continue to run.

- Q:I been playing the trombone for 6 years, do you think i could learn to play the baritone easily,which baritone is easier,3 valve or 4 valve.

- Some baritones have 3 valves, but the others have 4. The 3 valved ones are baritones and then the 4 valved ones are euphoniums.

- Q:It started leaking slowly so I opened the release valve for about 20 secs than closed it back to see if that would help, but now it leaks even more. So I had to shut off the water that's coming into the water heater and know I can't use the hot water in my house. Can someone help me please!!!!

- you will have to get it repalced.after they get old the spring inside starts to get weak.It will only get worst!Do not do a patch job,its not worth it.

- Q:i have a 1987 nissan 300zx and i can get the car to start unless its 40 degrees and when it does it idles hard. is this idle control valve or a fast idle valve??

- Could be.. Also could be dirty. Easy fix, remove the valve and spray carb cleaner in the hole.. Using a small brush, clean the bore that the valve rides up and down in. Also, inspect the valve while it is off the manifold. Harder fix: After cleaning the bore, replace valve with brand new one. Your car will have to relearn the idle after starting with the new valve or after you put the old one back in.. Start car, but do not put it in drive or give it any throttle until the computer has finished making adjustments. - Dave. (Long Island, NY)

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Swing Check Valve Wafer Type Double Disc Body Material CF3

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords