Suspension Ceilinng Grid System Suspension Ceilinng Grid System

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1,Structure of (Flat Suspension Grids) Description

t grids ceiling system

1 Materiel: Galvanized steel & prepainted

2 Size: H38&H32 H15

3 System: flat & groove

fut ceiling t grid

Materiel: Hot dipped galvanized steel & prepainted

Surface:Baking Finish

System: flat ceil & groove ceiling

t grids ceiling system

1 Materiel: Galvanized steel & prepainted

2 Size: H38&H32 H15

3 System: flat & groove

fut ceiling t grid

Materiel: Hot dipped galvanized steel & prepainted

Surface:Baking Finish

System: flat ceil & groove ceiling

2,Main Features of the (Flat Suspension Grids)

Shape:Plane,groove

Groove T bar ceiling grid (FUT) & FUT Ceiling Grid system is made of high quality prepainted galvanized steel,which guarantee the characters of moisture proof,corrosion resistanct and color lasting.The automatic cold roll forming and punching machineries guarantee the high precision.

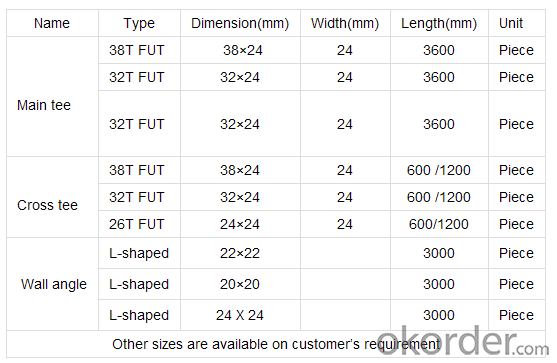

Standard size:

1. Main tee:38x24x3000/3600mm(10'),(12'); 32x24x3000/3600mm(10'),(12')

2. Cross tee:32x24x1200mm (4');26x24x1200mm (4')

3. Cross tee:32x24x600mm (2'); 26x24x600mm (2')

4. Wall angle:24x24x3000mm (10'); 22x22x3000mm (10'); 20x20x3000mm (10')

5. Thickness:0.25mm,0.27mm,0.3mm,0.35mm,0.4mm

6. The length, thickness and color can be provided in accordance with customers'

requirements.

3,(Flat Suspension Grids) Images

4,(Flat Suspension Grids) Specification

5,FAQ of (Flat Suspension Grids)

1. Convenience in installation, it shortens working time and labor fees.

2. Neither air nor environment pollution while installing. With good effect for space dividing and beautifying.

3. Using fire proof material to assure living safety.

4. Can be installed according to practical demands.

5. The physical coefficient of all kinds Suspension

Standard size:

1. Main tee:38x24x3000/3600mm(10'),(12'); 32x24x3000/3600mm(10'),(12')

2. Cross tee:32x24x1200mm (4');26x24x1200mm (4')

3. Cross tee:32x24x600mm (2'); 26x24x600mm (2')

4. Wall angle:24x24x3000mm (10'); 22x22x3000mm (10'); 20x20x3000mm (10')

5. Thickness:0.25mm,0.27mm,0.3mm,0.35mm,0.4mm

6. The length, thickness and color can be provided in accordance with customers'

requirements.

- Q:I would like to finish a large room in my basement and was wondering how hard a drop ceiling would be to install also drywall is already up but its just the bare drywall what else need to be done to the walls before theyre ready to be painted and my thinking is im just going to put some kind of rubber flooring in for now like would go in a garage since i could do that myself and there is no ac but ill probably just put a window unit in

- Drop ceilings aren’t that hard if you have common sense and some mechanical ability it’s a good DYI project if the drywall is already taped and finished with compound then just primer it with any drywall primer and paint

- Q:There are several layers of ladder when it is linked directly with the big core board, or how to do? Need to be fixed with wooden square?

- Light steel keel ceiling of the main dragon generally use 50 # light steel keel, if it is a large shopping malls, the need for time to the top of the maintenance, it needs to use 60 series of light steel keel, 60 series design is in accordance with the characteristics of the design , Can carry a weight of an adult, like a general ceiling as long as a hole to install a repair port on it ???? Light steel keel in the use of the wall when there are 50/75/100 series, different keels used in different occasions, if the space is relatively small with 50 type, you can save space, the general situation 75 vertical and most commonly used The

- Q:Decoration, said light steel keel gypsum board wall what is the use?

- Energy saving and environmental protection, policy support. Gypsum board production energy consumption is very low, in the regular annual production capacity of 20 million square meters of production lines per square meter double-sided monolithic gypsum board partition, the production of energy consumption does not exceed 3kg standard coal, and per square meter Clay brick wall production energy consumption is 4-12kg standard coal. In 2000, the former National Building Materials Bureau, the Ministry of Construction, the Ministry of Agriculture, the Ministry of Land and Resources, the Office of Building Materials (2000), published a list of large and medium cities with solid clay brick tiles. Light steel keel gypsum board will be the new wall materials in the most development potential of one of the products, but also to replace the solid clay brick is one of the most ideal and most economical wall materials.

- Q:I'm looking to mount the two front speakers and center speaker of a 5.1 surround sound home theater system onto my ceiling. My only concern is that I have ceiling tiles in this room, which means that the tiles can move. Can I mount speakers onto ceiling tiles? If I can't, are there any other solutions that will allow me to somehow have the speakers hang from the ceiling? All three speakers weigh 2.2 pounds each, and I guess combined with a mount it would be a little more.

- I have drilled ceramic tile many times using a carbide bit. To keep the bit in the right place while starting the hole, you simply take a pointed punch and hammer and tap a little chip in the tile surface. That will keep the point of the bit from wandering until you get started drilling By the way, the tiles were in place on a shower wall when I drilled them

- Q:I'm not sure if lots of stores sell it, but I've always wanted something to put on the floor that would project stars and space onto my ceiling. I'm not sure what that's called or where I could buy one. Anyone have any ideas?

- Command hooks do work very well, as other answerers have told you. But they are once and done. A cheaper solution, if you want to go around a window frame is stick 'um - at least that's what it is called in Canada. It is a putty that is sticky and really strong and you can remove it and re-use it. I have seen in in blue (not so inconspicuous) and white (almost invisible if you have white frames) and is strong enough to hold the lights and comes off without damaging the paint. This stuff is also awesome for holding candles straight in their holders.

- Q:What are the advantages and disadvantages of wood keel and light steel keel?

- Wood keel: easy to draw, what is the amount of small, complex structure of the special occasions. But the fire is not allowed to use a higher environment;

- Q:I would like to hang curtains from the ceiling to function like a room divider. But I can't make any holes in the ceiling, so does anyone know how I could do this? Or any alternatives to using some fabric as a room dividerThanks in advanced

- These okorder /products/cable-sys... Or you can use command hooks, heavy duty fish line.

- Q:What is the light steel keel double gypsum board partition wall

- National Standard Atlas 03J111-1 (light steel keel wall) Free to see this Atlas it, the main content is: light steel keel gypsum board light wall practice.

- Q:i just leased a unit in a new plaza. im going to put a barbershop in it. what i want to do is to remove the suspended grid ceiling so it can make the shop look bigger. i know their is sometype of requirement for the ac and i cant just leave it out in the open.. what do i need to do to meet the requirements? ive seen that they put some type of cover over it..

- The space between the drop ceiling and the actual ceiling is most likely being used as a return plenum. That is, the entire ceiling is your return duct. You will notice there are a couple egg crate tiles in the ceiling that allow for return air to get above the drop ceiling.The supply ducts are no doubt wrapped to avoid the dripping as stated by Dart otherwise you wouldn't have got the C.O. in the first place. The return is filled with hot, humid air that would've condensed on the cool ductwork and dripped onto the drop ceiling, but i doubt this is the case. They are insulated. If you were to remove this ceiling, you would have to spend the money to run return duct to the various points in the barber shop to ensure air changes and proper CFM (cubic feet per minute) exchange. Not to mention the reason a drop ceiling is there in the first place is to make the room smaller so the unit won't run as much and cost loads of money. Which brings up another problem. If you raise the ceiling in the room, you've just changed the heating and cooling demands for that roof unit and it may not be able to keep up. My advice is to leave the celing and all as it is. If you want to do something with it, why not paint a design on the tiles? If you know an artist, or artistic yourself, do a :Sisitine Chapel thing and have a mural on the ceiling. The tiles come down easily and it would be quite the conversation piece. OK so i'm not a decorator........

- Q:Where are they used? What is the use of aluminum slab and mineral wool board ceiling?

- Triangle keel, T-keel called paint keel, triangular keel is used in the wall, T-keel is divided into large T in the small T, is used to put the mineral wool board. Aluminum plate and mineral wool board ceiling can be used

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Suspension Ceilinng Grid System Suspension Ceilinng Grid System

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords