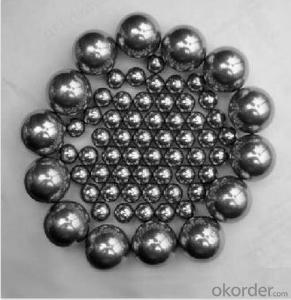

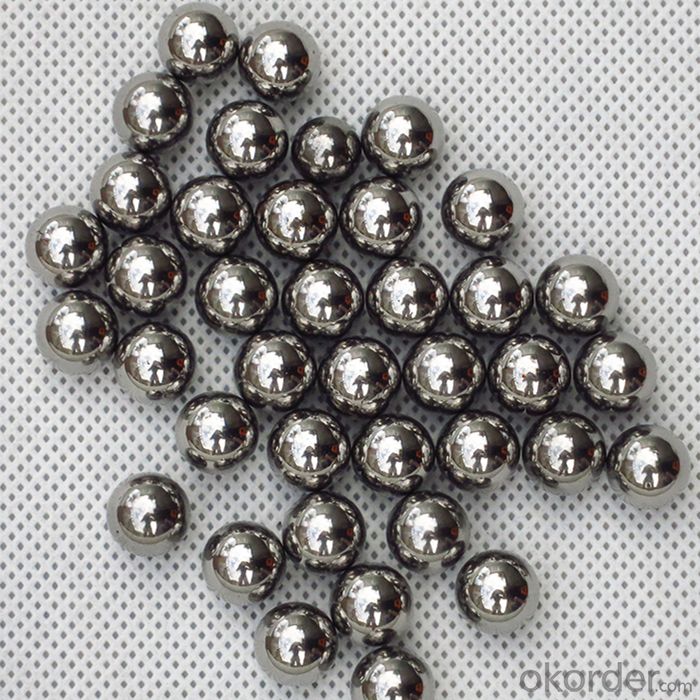

SUS304 Steel Shot 2mm Chemical Product Stainless Steel Ball

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Item specifice

Standard:

ASTM

Technique:

Cold Rolled

Shape:

Round

Surface Treatment:

Dry

Steel Grade:

304

Certification:

ISO

Thickness:

0.045-2.8mm

Length:

0.045-2.8mm

Net Weight:

20kg/bag

Packaging:

Standard Export Packing

Product Description

Stainless Steel Ball

1. Used in where good corrosion resistance is important, but hardness is not.

2. Offer good resistance to atmospheric corrosion, dyes, food environments, sterilizing solutions and many organic and inorganic materials.

| Stainless steel ball AISI 304 | ||||||||

| 1. Material | AISI 304/ SUS 304/ Wks 1.4301 | |||||||

| 2. Size Range | 1mm-180mm | |||||||

| 3. Grade | G40-1000 | |||||||

| 4. Hardness | 25-39 HRC | |||||||

| 5. Characteristic | (a)Good resistance to corrosion (b)Apply in where material toughness and resistance to corrosion are more important than hardness (c)Good corrosion resistance in the food environment, oxidizing solutions and most organic chemicals | |||||||

| 6. Magnetic | Much little | |||||||

| 7. Application | Valves, finger pumps, Aggressive applications without mechanical efforts | |||||||

| 8. Chemical composition | ||||||||

| C% | Si% | Mn% | Cr% | Ni% | P% | S% | N% | |

| min. | --- | --- | --- | 17.0 | 8.0 | --- | --- | --- |

| max. | 0.07 | 1.00 | 2.00 | 19.5 | 10.5 | 0.045 | 0.015 | 0.11 |

| 9.Packing | Standard: 10kg or 20kg per carton, 1 ton per pallet or as customer required | |||||||

| 10.Conditioning | dry or oiled | |||||||

| 11.Delivery time | Stock within a short time or 20 days. | |||||||

- Q:How is steel used in the production of mining equipment?

- Steel is commonly used in the production of mining equipment due to its strength, durability, and resistance to harsh conditions. It is used to manufacture various components such as buckets, shovels, drill bits, and machinery frames, ensuring they can withstand the rigorous demands of the mining industry.

- Q:What are the different types of steel nails and their applications?

- There are several types of steel nails, each designed for specific applications. Common types include common nails, finishing nails, roofing nails, and concrete nails. Common nails are versatile and used for general construction purposes. Finishing nails have a smaller head and are used for trim work or other finishing touches. Roofing nails are specifically designed for securing roofing materials. Concrete nails are hardened and used for fastening materials to concrete or masonry surfaces.

- Q:What are the common types of steel products used in the railway industry?

- The common types of steel products used in the railway industry include rails, sleepers, fasteners, and rolling stock components such as bogies, frames, and axles.

- Q:How are steel tubes used in the fabrication of bicycle frames?

- Steel tubes are commonly used in the fabrication of bicycle frames because they provide strength, durability, and flexibility. These tubes are cut and shaped into various lengths and sizes, and then joined together using welding or brazing techniques to form the frame structure. The steel tubes allow for the creation of lightweight yet robust frames that offer excellent stability and performance while cycling.

- Q:How is steel used in the production of medical equipment?

- Steel is commonly used in the production of medical equipment due to its strength, durability, and resistance to corrosion. It is used to manufacture various surgical instruments, such as scalpels, forceps, and scissors, as well as medical implants like joint replacements and orthopedic devices. Additionally, steel is utilized in the construction of medical equipment cabinets, tables, and frames, providing stability and reliability in healthcare settings.

- Q:What are the different types of steel sheets and their uses in the packaging industry?

- There are various types of steel sheets used in the packaging industry, including tinplate, galvanized steel, and stainless steel. Tinplate is commonly used for food packaging due to its corrosion resistance and ability to maintain product freshness. Galvanized steel sheets are used for heavy-duty packaging, such as shipping containers, as they provide strength and durability. Stainless steel sheets are often used in the pharmaceutical industry for packaging sensitive or corrosive substances, thanks to their resistance to chemical reactions and contamination.

- Q:How does steel compare to other materials like aluminum or wood?

- Steel is a versatile and durable material that offers several advantages over other materials like aluminum or wood. It is much stronger and more resistant to impacts, making it suitable for heavy-duty applications such as construction and manufacturing. Unlike wood, steel does not warp or rot, ensuring long-term stability. While aluminum is lightweight and corrosion-resistant, steel possesses greater tensile strength and can withstand higher temperatures. Additionally, steel is more cost-effective and sustainable, as it can be recycled indefinitely without losing its properties.

- Q:What are the different types of steel bolts and their uses in the construction of power plants?

- There are several types of steel bolts commonly used in the construction of power plants. Some of the most common types include anchor bolts, structural bolts, and high-strength bolts. Anchor bolts are used to secure equipment, machinery, and structures to the concrete foundation in power plants. They provide stability and prevent movement or displacement. Structural bolts, on the other hand, are used for connecting steel members together in power plant structures. These bolts are designed to withstand high loads and provide structural integrity to the plant's framework. High-strength bolts are specifically designed to withstand extreme forces and provide the necessary strength for critical connections. They are commonly used in the construction of power plants to connect heavy equipment, turbine foundations, and other crucial components. Overall, these different types of steel bolts play a vital role in ensuring the safety, stability, and structural integrity of power plants during their construction process.

- Q:What are the different types of steel angles and their applications in the manufacturing of machinery?

- There are several types of steel angles commonly used in the manufacturing of machinery. Some of the most common types include equal angles, unequal angles, and L-shaped angles. Equal angles have equal sides and are typically used for structural applications, such as providing support or reinforcement in machinery frames, brackets, or beams. They offer stability and strength, making them suitable for heavy-duty machinery. Unequal angles have different side lengths and are often used when specific strength or load-bearing requirements need to be met. They are commonly utilized in machinery components like supports, braces, or brackets, where different lengths are needed to distribute loads or provide stability. L-shaped angles, also known as corner or edge angles, are used for joining or connecting different parts of machinery. They are commonly employed in the construction of machinery frames, cabinets, or enclosures, providing structural integrity and stability. Overall, steel angles play a crucial role in the manufacturing of machinery by providing structural support, reinforcement, and connection points. The specific type of angle used depends on the intended application and the specific requirements of the machinery being manufactured.

- Q:What are the applications of alloy steel in the energy sector?

- Alloy steel finds numerous applications in the energy sector due to its exceptional strength, corrosion resistance, and heat resistance properties. It is commonly used in the construction of power plants, oil and gas pipelines, and offshore platforms. Alloy steel is also utilized in the manufacturing of turbine blades, reactor vessels, and other critical components in nuclear power plants. Its high temperature and pressure resistance make it suitable for steam boilers and pressure vessels. Additionally, alloy steel is used in the production of high-strength bolts and fasteners, ensuring the structural integrity and safety of energy infrastructure.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

SUS304 Steel Shot 2mm Chemical Product Stainless Steel Ball

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords